Pvc waterproof membrane (calendered laminating process) outdoor weather-resistant feasibility plan

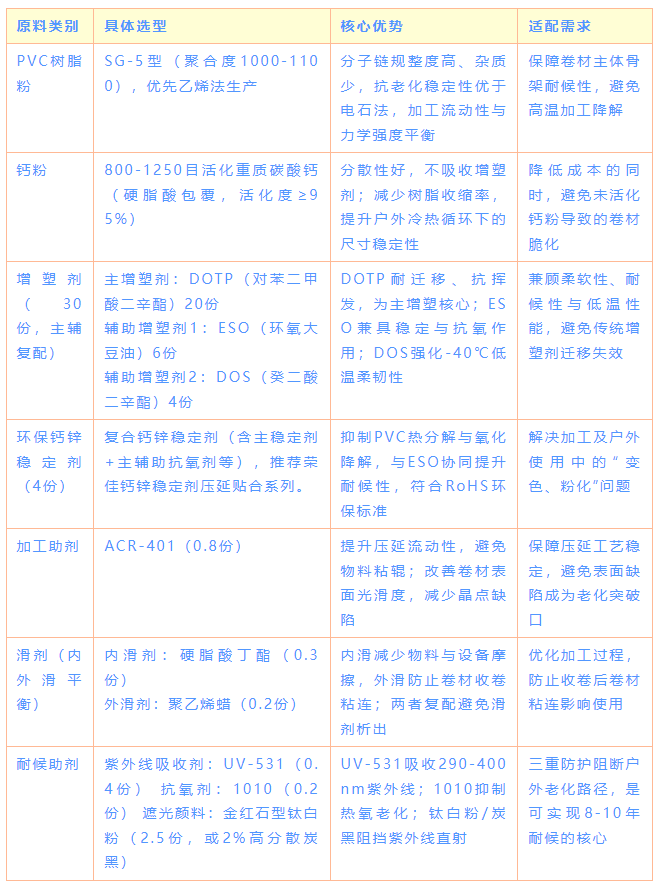

1. Material Selection: Focus on Weather Resistance Core, Balance Environmental Friendliness and Processability

Under the premise of meeting weather resistance requirements, control the total amount of additives to avoid excessive addition that could affect processability or increase costs. The specific formulation is as follows:

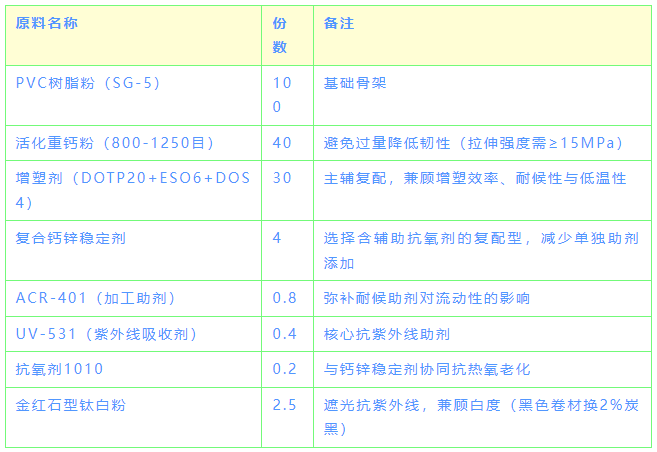

2. Formula Optimization: Balance Performance and Cost Based on 100 Parts of PVC

Recipe Core Logic

1. Weathering Enhancement:"UV absorbers + antioxidants + light-blocking pigments" form a closed-loop protection to address degradation issues caused by outdoor ultraviolet rays, high temperatures, and high humidity.

2. Performance balanceThe total number of plasticizers remains unchanged, utilizing a combination of DOTP as the main component and ESO+DOS as supplements, which ensures flexibility and prevents migration; the addition of processing aids and lubricants ensures stability during the calendering process.

3. Cost controllable:The total addition of weather-resistant additives is about 3.1 parts, increasing the cost by 800-1000 yuan per ton. Compared to traditional formulations, it offers a higher cost-performance ratio and can meet long-term weather resistance needs.

3. Process Control: Key Parameters in the Calendering and Lamination Process to Avoid Defects Affecting Weather Resistance

Focus on controlling the mixing, calendering, laminating, and post-treatment processes to reduce defects such as bubbles, crystal points, and delamination, as these defects can accelerate outdoor aging and shorten the lifespan.

1. Pre-mixing process (ensure uniform dispersion)

- EquipmentHigh-speed mixer + cooling mixer

Translate the above content into English, and output the translation directly without any explanation.

1. Low-speed stage (500r/min): Add PVC resin powder, calcium-zinc stabilizer, UV-531, and antioxidant 1010, and mix for 3 minutes to ensure the stabilizer and weather-resistant additives evenly coat the resin.

2. High-speed phase (1200r/min): Add plasticizers (DOTP→ESO→DOS in sequence), heat to 85-90℃, and maintain the temperature for 5 minutes to ensure that the plasticizers are fully absorbed by the resin without any free residue.

3. Supplementary Addition Stage: Add calcium powder, titanium dioxide, ACR-401, and lubricant, and mix at high speed until the temperature reaches 110-115°C (the material appears as loose granules). Immediately discharge into a cooling mixer and cool to below 40°C before discharging.

Core RequirementsThe mixed material has no clumps or white lumps, with a dispersion uniformity of ≥95%, preventing local insufficiency of additives that could lead to processing degradation.

2. Rolling Forming Process (Control of Thickness and Surface Quality)

- EquipmentFour-roller calender (roller diameter Φ600-800mm)

- Key Parameters:

Other parameters:

- Rolling speed: 8-12m/min (excessive speed may lead to uneven thickness, deviation must be ≤±5%);

- Roll gap adjustment: According to the target thickness (2.0-3.0mm, no less than 2.0mm for outdoor use), decrease sequentially as "first roll > second roll > third roll > fourth roll" for gradual compaction.

3. Bonding Process (if composite polyester substrate)

- Fetal base preprocessingPolyester tire is dried by hot air (80-90℃, for 3-5 seconds) to remove surface moisture, preventing bubbles after bonding.

- Fit parametersThe temperature of the laminating roller is 160-165℃, with a pressure of 0.8-1.0MPa. After laminating, it immediately enters the cooling roller (25-30℃) for setting, with a cooling time of ≥5 seconds to ensure a firm bond between the carcass and the PVC layer without delamination (delamination can lead to moisture infiltration, accelerating internal aging).

4. Post-processing Techniques

- Trimming and ReelingTrim width is controlled within ±5mm, rewinding speed is synchronized with calendering speed (8-12m/min), and rewinding tension is 50-80N (excessive tension can easily cause stretching and deformation, while insufficient tension can lead to looseness).

Aging treatmentAfter rolling, place it in a curing chamber (40-50°C, humidity ≤60%) for 24 hours to allow the plasticizer to further diffuse evenly, reducing the shrinkage rate in the later stage (shrinkage rate after curing ≤1.5%).

4. Feasibility Verification of the Plan

WeatherabilityAccording to GB/T 18244-2000, conduct a xenon lamp accelerated aging test (irradiance 0.71W/(m²·nm), 65℃, 50% humidity). After 1000 hours, the tensile strength retention rate should be ≥80%, and the elongation at break retention rate should be ≥70%, corresponding to an outdoor lifespan of 8-10 years.

2. Processing FeasibilityThe formulation exhibits good material flow at a calendering temperature of 150-170°C, without sticking to the roller or forming crystalline points. After lamination, the surface of the rolled material is smooth, with a thickness deviation of ≤±3%.

3. Environmental Compliance:All materials comply with RoHS standards, the plasticizers are free of phthalates, and the calcium-zinc stabilizers contain no heavy metals, meeting the requirements for outdoor environmental use.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track