Porsche, BASF, And BEST Jointly Complete Breakthrough Pilot For Chemical Recycling Of Automotive Waste

On September 30, Zhuanshu Vision cited Porsche news, Porsche AG (Porsche AG, in cooperation with BASF SE and with the assistance of technology partner BEST Bioenergy and Sustainable Technologies GmbH, has successfully completed a joint pilot recycling project for mixed waste from end-of-life vehicles. The project verified the feasibility of recovering high-performance plastics from automotive shredder residue (ASR), which consists of a mixed waste made up of foam, plastic, films, and paint particles, primarily sourced from end-of-life vehicles. Currently, such complex material mixtures can only be processed through thermal recovery.

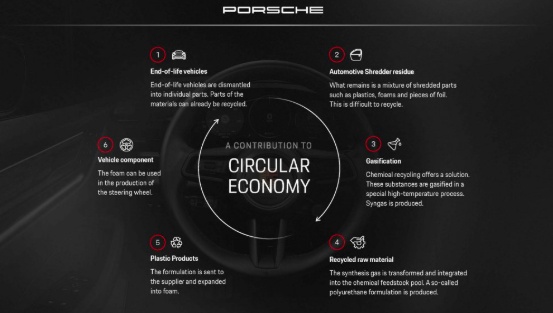

Porsche is committed to promoting a circular economy in the automotive manufacturing sector and has set a goal to increase the proportion of recycled materials in its vehicles.

Gasification technology, as a form of chemical recycling, can convert mixed waste into high-value new raw materials, such as feedstock for plastic production. In the future, this technology is expected to replace existing thermal recovery processes and complement Porsche's circular economy strategy. Chemical recycling is particularly suitable for plastic waste that cannot be processed through mechanical recycling due to technical, economic, or ecological reasons.

This pilot project aims to assess the potential of automotive shredder residue as a future source of recycled materials. The experiment utilizes an innovative recycling process: for the first time, it completely abandons fossil-based materials, instead combining automotive waste with bio-based materials (such as wood chips). Through advanced gasification technology, plastic waste is converted into syngas at high temperatures.

In BASF's integrated syngas production network, new plastics are produced and supplied to component manufacturers.As part of the pilot project, this recycled material, such as a type of polyurethane formulation, is used to produce new steering wheels through the mass balance approach (*).

Porsche steering wheel productionPorsche AG 2025

“This type of pilot project allows us to assess how to further develop the circular economy in the field of sustainability at Porsche, as well as how to integrate chemical recycling into our long-term strategy,” said Dr. Robert Kallenberg, Head of Sustainability at Porsche. “We are testing new recycling technologies with partners to increase the share of recycled materials, to obtain previously unusable recycled resources, and to evaluate new processes for waste streams currently utilized through thermal energy.”

"BASF offers a wide range of recycling solutions, and we firmly believe that a combination of multiple recycling technologies is necessary to achieve recycling goals. We prioritize advancing mechanical recycling and continuously improving its efficiency. The type of waste and the level of sorting determine the most suitable technology. We are convinced that complementary technologies such as chemical recycling are needed to handle the remaining waste that is still being incinerated," explained Martin Jung, President of BASF's Performance Materials division.

The raw materials produced through the gasification process are comparable in quality to traditional raw materials. The products made from these materials meet the requirements for high-performance plastics, and can therefore also be used for safety-critical components.

When these new types of circular feedstocks are introduced into large, complex, and continuously operating production facilities, they mix with conventional fossil feedstocks and are processed into plastic precursors. Through the mass balance method, the new (secondary) feedstocks are traced to the final product. The product and production site are based on internationally recognized systems such as...ISCC PLUS or REDcert² certified by independent auditing organizations.

Porsche's Circular Economy Strategy

Porsche is committed to the responsible and economical use of raw materials, as well as the long-term utilization of vehicles and the materials used in them.Under the sustainable development framework of the "circular economy," Porsche is committed to promoting more eco-sustainable materials and circular concepts within the vehicle value chain. This includes initiatives such as high-voltage battery closed-loop recycling projects, the use of recycled materials, waste reduction, and the remanufacturing of vehicle components.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track