Polyolefin Giants Expand Production! Wanma and Wanhua Ignite High-End Market "Battle"

On October 9th, Nordic Chemicals announced a significant investment to expand the cross-linked polyethylene (XLPE) production capacity at its Stenungsund plant in Sweden.

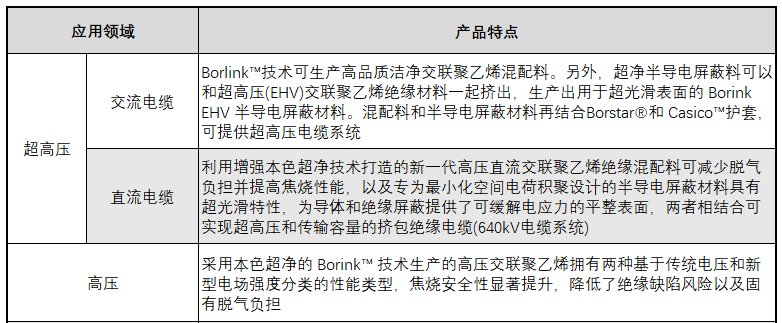

Including: 1. Establishing a new medium-voltage cross-linked polyethylene (MV XLPE) production facility to produce the new generation of homopolymer XLPE grades; 2. Expanding the production capacity of high-end cross-linked polyethylene (HV/EHV XLPE) for high-voltage and ultra-high-voltage applications; while also expanding the closed-loop circulation system from monomer to final packaging to ensure high standards of product cleanliness.

It is reported that the project is scheduled for completion in 2026 and will be put into operation in 2027.

It is worth mentioning that Nordic Chemicals, along with its joint venture Borouge, has announced that it will double its relevant capacity by the end of 2027. The expansion project of the 100,000-ton XLPE plant at Borouge's Ruwais facility in the UAE is expected to be put into operation by the end of 2025 to meet the surging demand for high-end cables.

Trillion-dollar track new blue ocean

In recent years, the global interconnection of large power grids, integration of new energy sources, and construction of offshore wind power have progressed simultaneously, driving up the global demand for cables. The market size is expected to rise from 1.5 trillion yuan in 2023 to 2 trillion yuan by 2030. As a key material ensuring the safe operation of cables, the reliability of insulation materials is crucial.

High-voltage cables are categorized by their main insulating medium into oil-filled cables, oil-impregnated paper cables, and extruded insulation cables. Currently, high-voltage extruded cables commonly use XLPE as the main insulating material.

XLPE (Cross-Linked Polyethylene) is a thermosetting resin made from polyethylene cross-linking. It has stable chemical properties, excellent low-temperature resistance, and can withstand acid and alkali corrosion. It is a high-quality electrical insulation material, especially advantageous in the field of long-distance, high-capacity power transmission.

China's "Chokehold" Dilemma

XLPE's main downstream cable fields can be divided into low voltage, medium voltage, and high voltage.

High voltage cables are the main component of this market. Data shows that by 2025, this segment's market share is expected to be close to 53%. However, in terms of insulation materials, the ultra-high voltage material products in the international market are mainly monopolized by Borealis.

In recent years, to achieve the localization of high-end polyethylene materials, domestic companies such as Zhejiang Wanma, Qingdao Hanlan, Jiangsu Dewei, and Wanhua Chemical have successively embarked on localization development. Currently, Wanhua Chemical, leveraging its upstream and downstream integration advantages and utilizing pipeline transportation, has achieved integrated supply of base materials and modified materials, with pilot production output of XLPE products at ultra-high voltage levels.

At present, although domestic insulating materials have achieved certain results, with the increasing number of high-voltage cable projects planned in China and the continuous improvement of cable operating voltage levels, higher requirements are being placed on the overall performance of XLPE insulating materials.

-

Insulation performance

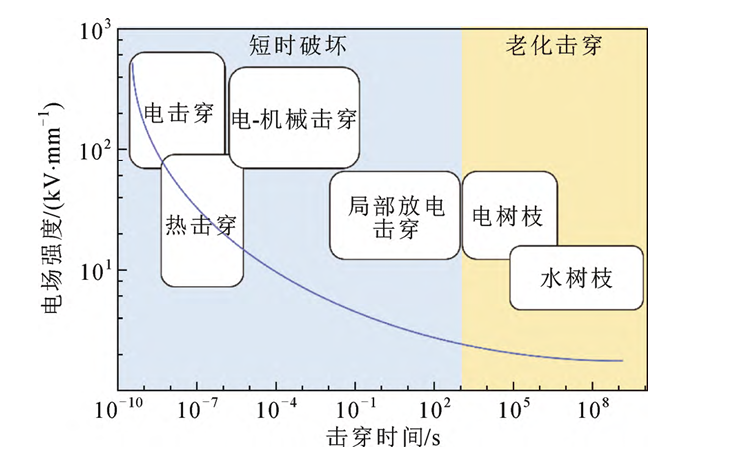

High-voltage and ultra-high-voltage direct current cables have become a research hotspot due to their high transmission efficiency, low line losses, and low maintenance costs. The demands on XLPE insulation mainly include low DC conductivity and superior space charge characteristics. These properties will directly determine whether the core risk leading to cable failure—insulation breakdown—can be avoided.

Specifically, in the field of DC cables, the conductivity and space charge characteristics of XLPE respectively dominate different forms of breakdown risk.

Different breakdown modes are closely related to electric field strength and action time.

1. Conductivity is primarily associated with the risk of "electrical breakdown."

Influencing mechanism:

The electric field distribution of XLPE cables differs under AC and DC voltage. Under DC electric field, the electric field distribution of the cable insulation layer is no longer determined by the dielectric constant as it is under AC electric field, but rather depends on the conductivity of the material.

The conductivity increases exponentially with the rise in load temperature. When the cable operates under direct current voltage, the insulation layer forms a temperature gradient from the inside to the outside and from high to low. This results in the inner resistance, which is at a higher temperature and has a higher conductivity, being smaller, while the outer resistance, which is at a lower temperature and has a lower conductivity, being larger.

According to circuit principles, more voltage will be distributed in areas with high resistance, leading to "field reversal"—the electric field strength on the outside of the insulating layer is higher than on the inside, causing a risk of breakdown.

2. Space charge is mainly associated with the risk of "aging breakdown."

Influencing mechanism:

The accumulation of space charge can create a significant local electric field within the insulation. This persistent and excessive electrical stress can gradually lead to material degradation, trigger partial discharge, and ultimately result in insulation aging and breakdown after long-term accumulation.

Furthermore, in actual operation, the aforementioned two characteristics are interrelated and exacerbate each other. Their combined effects influence the actual withstand voltage strength and lifespan of the insulation system.

-

Cleanliness

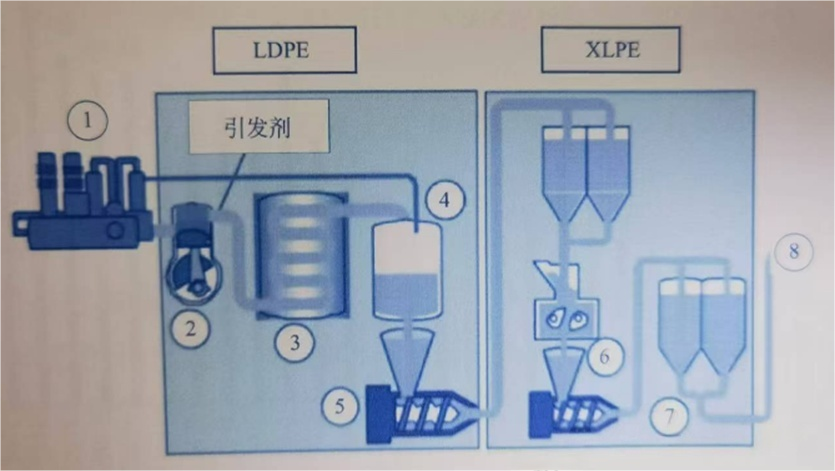

Regardless of the type of breakthrough, achieving a complete and closed-loop ultra-clean control process from substrate polymerization to insulation material production is the most fundamental and crucial prerequisite. It simultaneously addresses the two major issues of abnormal conductivity caused by impurities and the accumulation of space charge.

Currently, the ultra-clean route is the most mature. Borealis has achieved mass production of ultra-clean XLPE insulation materials through dedicated polymerization equipment and full-process clean control, while domestically, breakthroughs are still needed in base material synthesis and impurity detection technology.

Borlink™ Polyethylene Production Process

The sources of impurities in XLPE come from every stage of the entire long process, including raw materials, polymerization, transportation, mixing, degassing, and packaging. The purpose of Nordic Chemicals expanding its closed-loop integrated production system is also in line with this.

Characteristics of Nordic Chemical's High/Ultra-High Voltage XLPE Products

-

Stable extrusion process

High-voltage XLPE cable extrusion is typically carried out by co-extruding three layers of molten material (inner shielding, insulation, outer shielding) onto a metal conductor, followed by a cross-linking reaction to produce the insulated core.

The control of the insulation material melt extrusion process is a key link in producing high-quality cable products. It typically requires a lower melt temperature to ensure a faster startup speed for the screw extruder and to avoid localized high temperatures in the flow channel, preventing scorching (premature cross-linking, loss of fluidity, and reprocessing capability).

Additionally, due to limitations in storage, transportation, and other aspects, there is a length limit in the manufacturing of single high-voltage submarine cables, which cannot meet the requirements for continuous extrusion. Therefore, improving the rheological properties, extrusion stability, and scorch resistance of cable insulation materials, as well as optimizing the insulation extrusion molding process, are key directions for future research and development of ultra-high-voltage insulation materials.

In 2018, domestic optical fiber cable giant Hengtong used Nordic Chemicals LS 4201 EHV XLPE insulation material to achieve a continuous extrusion of an 18-kilometer-long 500 kV submarine cable, marking the completion of China's first domestically produced 500 kV submarine cable, which is used in the Zhoushan interconnection project.

Borealis is one of the top ten polyolefin producers in the world and a leader in the basic chemicals and plastics recycling sector in the European market.

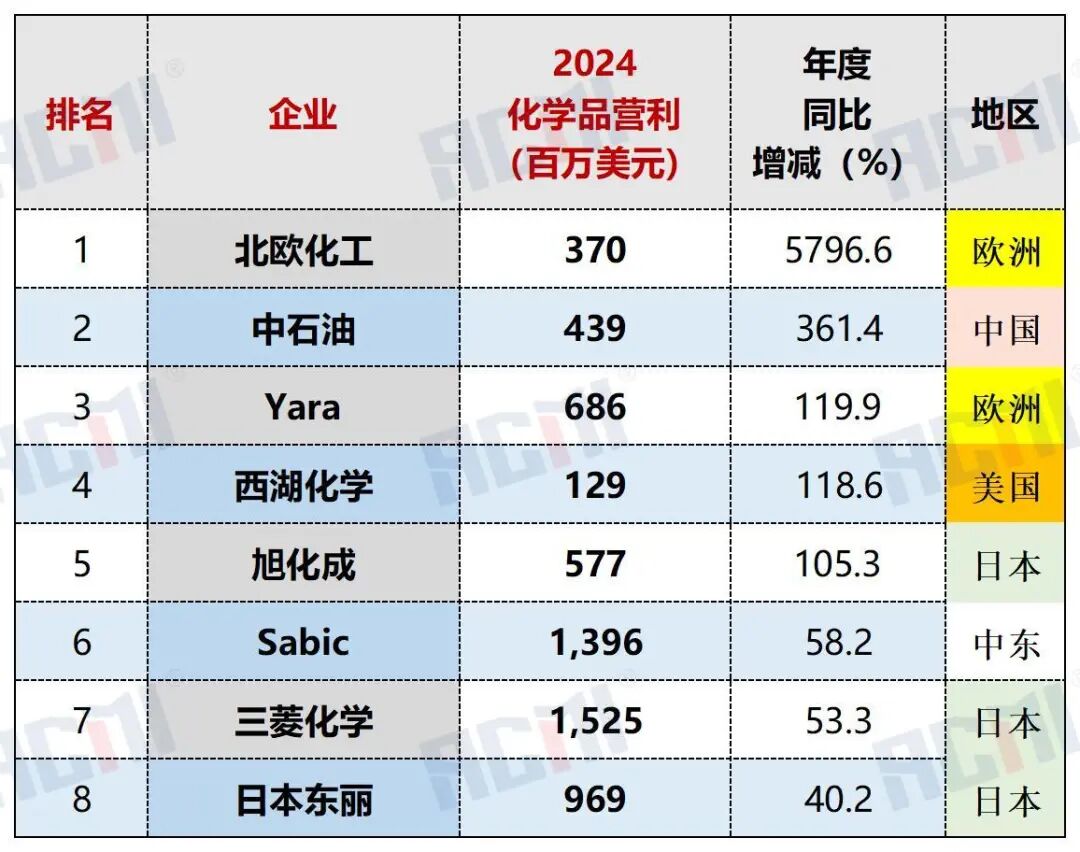

In 2024, the profitability of its core polyolefin business improved significantly, and the company achieved a staggering profit increase of 5796.6%, making it the company with the largest annual profit growth on the list of the world's top 50 chemical companies.

References: Company website, Chemical New Materials, Internet

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track