Plastic Energy Turns Chemical Recycling Byproducts Into Circular Fillers for Rubber

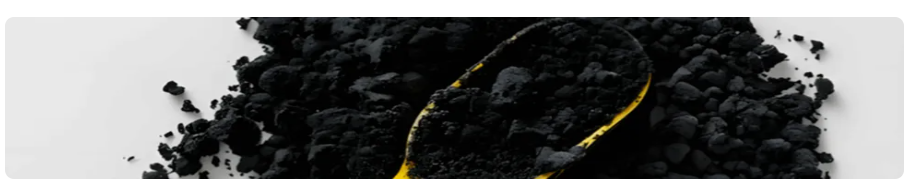

Plastic Energy is considered the first plastic chemical recycling company to commercialize the by-product "char" from the TAC™ chemical recycling process, under the name TACFILLER.

This groundbreaking product offers a low-carbon circular alternative to carbon black, an unsustainable material primarily used in rubber manufacturing to improve rubber performance.

REACH registered round fillers for rubber applications

The arrival of this milestone comes at a time when the rubber industry is facing increasing pressure to reduce emissions and comply with regulations such as the EU's End-of-Life Vehicles Directive, which requires a higher recovery content for motor vehicle components to minimize environmental impact.

TACFILLER provides a scalable and sustainable solution. It is the first product of its kind to achieve REACH registration (a regulation applicable to most chemicals manufactured or imported into the UK), which will help the rubber industry significantly reduce emissions and achieve recycling content targets as a direct alternative to carbon black.

Carbon black is added to rubber to increase its durability. However, its production from fossil fuels is emission-intensive, releasing 2.9 to 79 million tons of carbon dioxide annually worldwide.

In contrast, TACFILLER is made from post-consumer plastic waste, reducing the reliance on virgin fossil fuels. Plastic Energy conducted a lifecycle assessment of TACFILLER and found that its production emissions are 89% lower than traditional carbon black.

TACFILLER is derived from Plastic Energy's proprietary TAC.™Chemical recycling process transforms hard-to-recycle post-consumer plastic waste into TACOIL.™TACFILLER is a type of recycled material used to replace fossil fuels in the production of new plastics. Compared to incineration, this process diverts plastics from landfills and burning, reducing waste and lowering emissions by up to 78%. The addition of TACFILLER increases Plastic Energy's potential total recycling rate to nearly 90%, further enhancing the circularity of its process.

Ian Temperton, CEO of Plastic Energy, said:Carbon black is energy-intensive, and the rubber industry needs alternatives. We are proud to lead our industry by creating new circular products through the utilization of plastic waste. Globally, less than 10% of plastic is recycled, but it is a valuable resource that should be reused. Our technology enables us to reduce plastic waste sent to incineration and landfills by finding sustainable uses in the production of new plastics and now rubber. We are offering a pioneering product that is both better for the environment and commercially viable.

Plastic Energy is currently working with several leading manufacturers, including Standard Profil, to ensure that TACFILLER is fully compatible for integration into their products.

Standard Profil Group R&D Materials Senior Expert Yusuf Güner stated:We boldly explored the use of TACFILLER as a partial substitute for carbon black in our products. After a series of rigorous tests, we have verified its feasibility and are encouraged by the results. This opens up exciting possibilities for future applications, and we will continue to evaluate it with curiosity and caution.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track