Pioneer Machinery: Custom Solutions for Plastic Recycling and Washing, Exported to 80+ Countries After 40 Years of Expertise

Shunping County Pioneer Machinery Manufacturing Co., Ltd., established in 1984, is a high-tech enterprise specializing in the research, design, manufacturing, and sales of plastic cleaning and recycling equipment. After nearly 40 years of industry dedication, the company has grown to become a leading manufacturer of plastic recycling equipment in the northern region, with products exported to over 80 countries and regions worldwide, providing efficient and intelligent solutions for the plastic recycling and processing industry.

The company is headquartered in Shunping County, Hebei Province, covering an area of 35,000 square meters, with a standardized production plant of 18,000 square meters, equipped with advanced manufacturing equipment and a professional R&D team. Relying on strong technical strength and rich industry experience, we are committed to providing customers with customized plastic recycling cleaning systems, covering cold and hot washing solutions for various materials such as PET, HDPE, PP, ABS, PS, and PC.

— 1 —Core Business and Product Advantages

Provide high-quality PET cleaning solutions such as RPET bottle flakes, AAA-grade sheets, and blue-white flakes based on the characteristics of different raw materials and customer needs. Optimize processes such as label removal, crushing, sorting, and rinsing to ensure the purity and production efficiency of the final product.

02 Diversified plastic treatment solutions:

Design customized hot or cold washing systems for materials such as HDPE, PP, and ABS, adaptable to various forms of raw materials including films and rigid plastics, to improve recycling rates and economic efficiency.

The company adheres to innovation-driven development, establishing long-term cooperation with domestic and international plastic production bases and leading enterprises. We continuously optimize equipment energy consumption, automation level, and environmental performance to help customers achieve green and low-carbon production. With outstanding product quality and comprehensive after-sales service, Pioneer Machinery has become a trusted partner in the global plastic recycling industry. In the future, we will continue to drive technological innovation, promote resource recycling, and create greater value for customers worldwide.

— 2 —Product Introduction

01 All-network spin dryer:

This equipment utilizes high-speed centrifugal dewatering technology and is specially designed for sheet plastics such as PET, PE, PP, and ABS. Through powerful rotational separation, it reduces the moisture content of the material to below 2%. Equipped with a wear-resistant stainless steel screen and a high-efficiency power system, it ensures long-term stable operation, high output, and low energy consumption. The automated discharge design eliminates the need for manual intervention, making it economical and practical—an ideal choice for plastic recycling and dewatering.

The device features an integrated alloy steel shaft design, equipped with high-hardness SKD-11 and other special steel blades to ensure exceptional wear resistance and sharpness. For hard plastics such as PET bottles, it utilizes high-pressure shear crushing technology to achieve efficient shredding, increasing productivity by more than 30%, with uniform and fine flakes. The bearings and power system are optimized for stable operation and long service life, making it suitable for high-load continuous operation.

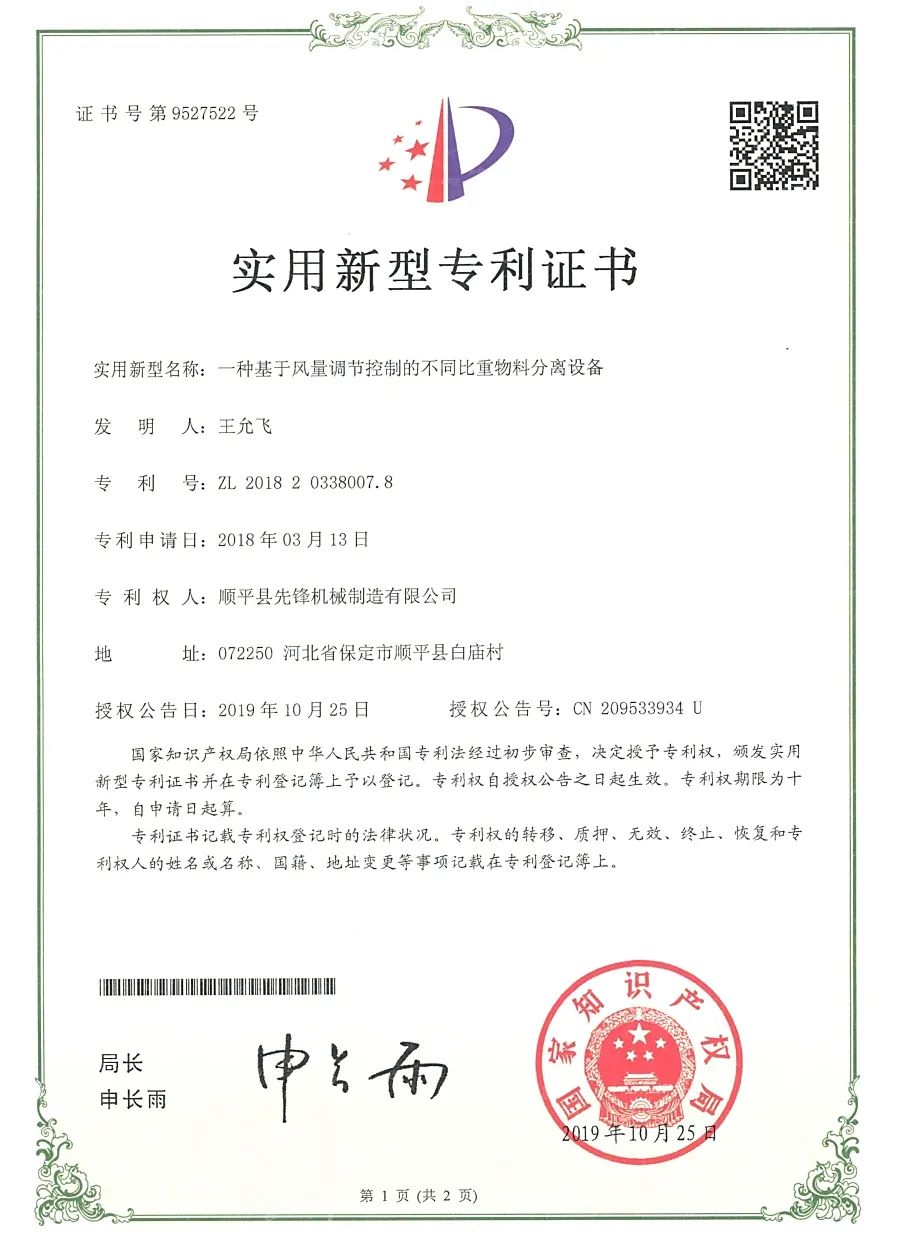

This equipment adopts centrifugal air separation technology (patent number: ZL: 2018 2 0338007.8). After the bottle flakes are spun dry and enter the air separation cylinder, they are efficiently separated from the label paper by utilizing the difference in specific gravity under the action of high-speed rotating airflow. The patented design of the guide vanes and wind speed adjustment system ensures sorting precision, with a purity of over 99% for the clean flakes, thoroughly solving the problem of high carryover rates in traditional processes. With stable performance, annual sales have exceeded 700 units and the equipment is widely used in plastic recycling processing bases nationwide.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track