Packaging costs drop instead of increase? digital labels are here! food giants chacha, pepsi, and master kong have joined!

"Ingredients list, expiration date, the text is too small to read?"

Many friends are likely

I've encountered this situation before.

To address this pain point

Audible, playable, zoomable

Pre-packaged food digital labels are here!

What is the difference between numeric labels and entity labels?

What impact do businesses have on consumers?

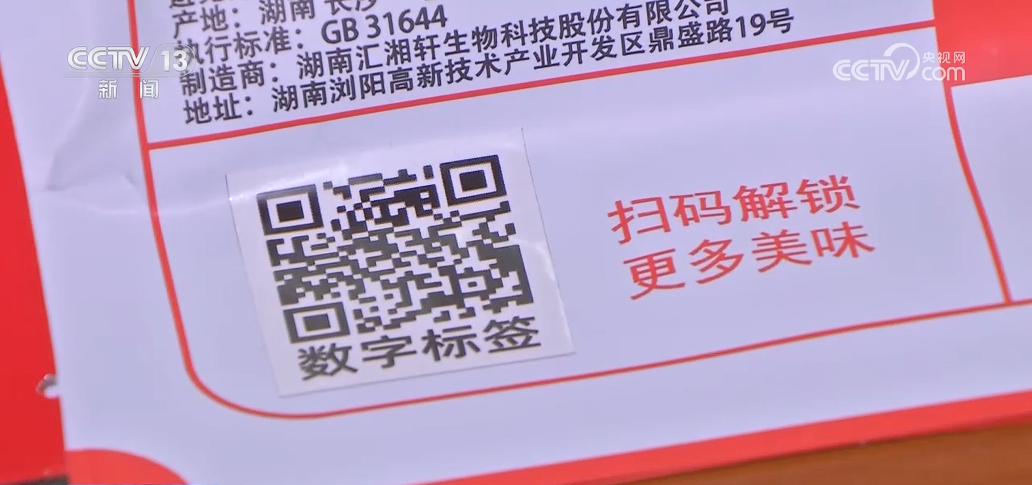

Scan the food ingredient list to view it.

On September 8, the National Health Commission and the State Administration for Market Regulation issued the "Announcement on Matters Related to the Implementation of Digital Labels on Pre-packaged Foods," further detailing the application requirements for digital labels.

Compared to physical labels, digital labels have no space limitations and offer richer content.

Consumers can scan QR codes with mobile devices such as smartphones to access digital label pages. With features like page zoom, voice recognition, and video explanations, they can achieve the "audible, playable, and magnifiable" functionality of food label information. This effectively addresses the issues of "not finding, not seeing clearly, and not understanding" label information.

The "Announcement" clearly allows the use of digital labels to display more legitimate information that cannot be shown due to the limited space on physical labels, including: specific sources of ingredients and production process details, product origin traceability information, detailed consumption recommendations, food safety and nutritional characteristics descriptions, and full-chain product traceability information.

In addition, the announcement strongly encourages the integration of digital label QR codes with other QR codes on the packaging to achieve a unified code.

The National Health Commission has designated 2025 as the "Year for the Promotion of Digital Food Labels" and will organize provinces, cities, and related food industries across the country to promote the application of digital labels.

Cost-saving, energy conservation, and emission reduction

Digital labels are not just "adding another code."

For enterprises, digital labels are not just about "adding an extra code."

Digital labeling provides convenience for business production, operation, and management.

The pilot enterprise for digital labels, ChaCha Food, has previously stated that for foods with more label information, there were inconveniences in label design. Digital labels increase the flexibility of pre-packaged food label identification, enhancing the efficiency and accuracy of the company's food label management work.

In addition, using digital labels can save packaging costs for food companies, reduce ink usage, and be more environmentally friendly.

Currently, enterprises such as Mengniu, Luhua, Pepsi, Feihe, Sanyuan, Master Kong, Starbucks, Shuanghui, and Bright Dairy are actively responding, with over a thousand food products across major categories such as dairy products, grain and oil, baked goods, meat products, and beverages now using digital labels.

Besides the numeric labels

The market has also seen the emergence of various innovative labels.

Anti-counterfeiting labels, temperature-sensitive labels, etc.

Implemented functions such as anti-counterfeiting, interaction, and data traceability, widely used in industries like food and beverage packaging, logistics, and healthcare, significantly enhancing product value and user experience.

Next, let's explore together with Xiangxiang↓

What is the secret behind a small label?

01 Label Film Material Selection

Label film refers to a type of thin film material used for making the facestock or functional substrate of self-adhesive labels. It has good printability, processing performance, weather resistance, and stability.

The food and beverage industry has specific requirements for labels: firstly, labels need to have high safety and, as food contact materials, must comply with FDA and EU standards; secondly, they should be water-resistant, oil-resistant, and able to withstand low or high temperature environments (such as pasteurization); additionally, labels need to have a strong visual impact to attract consumer attention.

Common label film materials used in the food and beverage industry include:

Transparent BOPP film: Suitable for transparent bottled products such as juice, dairy products, and tea drinks, showcasing the internal contents.

White PP film: suitable for opaque bottles or cans, with strong coverage.

Frozen grade PE film: Suitable for refrigerated and frozen products, does not peel or warp at low temperatures.

Metallic effect films (such as gold and silver dragon films): Enhance the grade of high-end foods, such as wine and imported chocolate.

……

02 The printing process of labels

Printing technology is the core of visual expression in packaging, with different techniques offering advantages in terms of color effects, low-temperature resistance, cost, and more.

Flexographic printing

Flexographic printing is characterized by fast ink drying, strong adaptability, and lower cost. The flexible plates used in this process have a certain elasticity, allowing for clear printing on non-absorbent film materials such as PE and PP. The inks are mostly solvent-based or water-based systems, and after low-temperature curing, they can maintain color stability in freezing environments below -18°C, reducing the likelihood of fading or cracking.

For example, the outer plastic sealing film of commonly seen bagged ice cream and cup ice cream mostly uses flexographic printing technology, which can achieve multi-color overprinting to meet the basic display needs of brand logos and product patterns.

Gravure printing

Gravure printing achieves printing by engraving recessed images and texts on the printing cylinder, utilizing the filling and transfer of ink. Its advantages lie in high color saturation, strong layering, and precise detail reproduction, capable of printing complex effects such as metallic gloss and gradient colors, enhancing the high-end texture of products.

Gravure printing inks have stronger adhesion to film materials, and after high-temperature curing, they exhibit excellent abrasion resistance and low-temperature performance. Even during long-term frozen storage or transportation, the packaging appearance can remain intact.

Digital printing

Digital printing technology has the advantages of no need for plate-making, quick response, and strong personalization. It can print images and text directly on materials such as film and paper, supports variable data printing, and its color reproduction is close to that of gravure printing.

Meet the diverse needs of the industry

CHINAPLAS 2026 International Exhibition on Plastics and Rubber

Convergence of printing, label innovation materials and processes

Support the packaging industry

Safer, smarter, and greener development

▲PETG shrink film is typically used for gravure/flexographic printing to produce shrink labels for beverage bottles. (Photo taken at CHINAPLAS 2025 International Exhibition on Plastics and Rubber, the same applies below.)

▲Surrounding label film, white label film.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track