Overall Scale of the Global PE-XC Pipe Industry, Market Shares and Rankings of Major Enterprises at Home and Abroad

PE-XC pipe is a type of polymer material pipe, scientifically known as radiation cross-linked polyethylene pipe. It is produced using high-density polyethylene (HDPE) as the raw material, along with some auxiliary materials (such as antioxidants). The pipe is first extruded (uncrosslinked) in a plastic extruder, and then the extruded uncrosslinked pipe is exposed to radiation (using an electron accelerator or a cobalt-60 irradiation station). By utilizing high-energy rays (electron beams or γ rays), radiation cross-linking is carried out. Polyethylene pipes produced by this method are called radiation cross-linked polyethylene pipes.

01

PE-XC pipes, as the fourth generation of plastic pipe products, are currently in a critical stage of transitioning from technological maturity to market expansion.

PE-XC (Electron Beam Cross-Linked Polyethylene) pipes are a subcategory within the PEX (Cross-Linked Polyethylene) pipe market. Unlike PE-Xa (Peroxide Cross-Linked) and PE-Xb (Silane Cross-Linked), PE-XC utilizes high-energy electron beam irradiation for cross-linking – a clean, additive-free process that produces pipes with excellent mechanical properties and long-term stability.

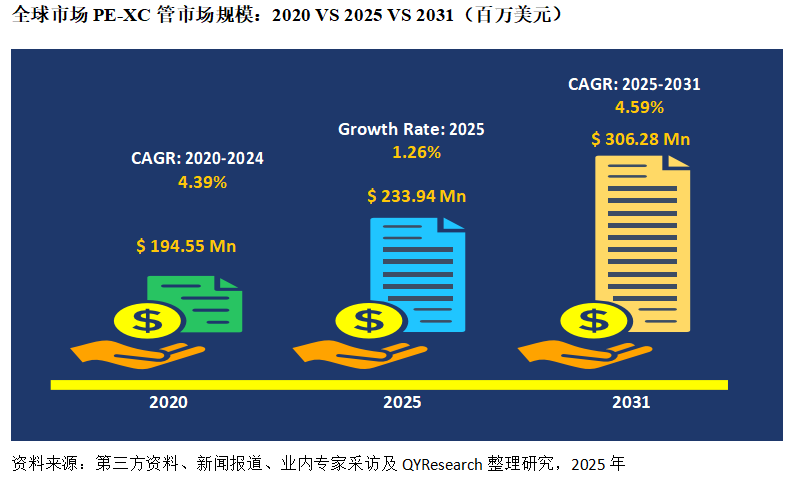

According to research team surveys and statistics, the global PE-XC pipe market reached sales of USD 231 million in 2024 and is expected to reach USD 306 million by 2031, with a compound annual growth rate (CAGR) of 4.59% from 2025 to 2031.

In terms of regional development, Europe, as the birthplace of PE-XC pipe technology, accounted for 45.76% of the global market share in 2022, with a market size of $106 million in 2024. The North American market shows a clear dual structure; in the residential sector, PE-Xa still holds the major share, while in the commercial sector, the share of PE-XC is rapidly increasing. The Chinese PE-XC pipe market is cost-sensitive and currently limited, exhibiting typical developing market characteristics. In 2024, the Chinese PE-XC pipe market size is $18.48 million, accounting for 8.00% of the global market, and is expected to reach $26.35 million by 2031, with the global share rising to 8.60%.

Although PE-XC pipes still hold a minority share in the overall PEX market, they are attracting attention due to their environmental characteristics, dimensional stability, and suitability for underfloor heating and drinking water applications.

02

Environmentally-oriented market demand

One of the core advantages of PE-XC pipes lies in its non-chemical crosslinking process. The crosslinking is achieved through high-energy electron beam irradiation, rather than using peroxide (PE-Xa) or silane compounds (PE-Xb).

This ensures that PE-XC pipes have no chemical residues; low volatile organic compound (VOC) emissions, in compliance with green building certification; and a stable and controllable cross-linking process, effectively improving product quality.

Competitive positioning in the high-end market

Although the production cost of PE-XC is higher than that of PE-Xb or PE-RT, it is positioned as a high-end technological alternative, particularly suitable for systems with strict temperature control requirements, high-end residential complexes, commercial buildings, and green environmentally-friendly buildings. Its high price is usually justified by its performance and sustainability advantages.

Regional Differentiated Development Pattern

Germany, Austria, Switzerland, and the Nordic countries: the most mature markets, with a high penetration rate of PE-XC in underfloor heating and drinking water fields.

Japan and South Korea: Strong application in ecologically certified buildings.

North America: Niche applications are continuously growing, especially in the fields of schools, hospitals, and prefabricated housing.

China and Southeast Asia: The market demand is limited, but driven by downstream demand and high-end construction, the market is continuously growing.

Application scenarios continue to expand

Based on the traditional application areas of building water supply and drainage, the boundaries of industry applications are continuously being, and potential emerging fields include:

Data center liquid cooling system; solar thermal utilization; medical gas delivery.

The standard system is gradually improving.

Currently, with the continuous development of the market, the standardization of PE-XC pipes is accelerating.

International Standards: ISO 15875 is continuously being updated; Regional Standards: The EU EN standard system is the most comprehensive; Chinese Standards: GB/T 18992 is currently under revision.

03

Growth in demand for the high-end construction market

The global green building market is growing at an annual rate of 12%, driving demand for high-end piping materials.

The policy of finely decorated houses in China promotes the application of PE-XC pipes in high-end residential buildings.

The demand for underfloor heating systems is continually growing.

The rapid global adoption of low-temperature hydronic underfloor heating systems is the main driving force behind the development of PE-XC pipes.

The dimensional stability, flexibility, and heat resistance of PE-XC make it an ideal choice for embedded heating circuits under concrete or wooden floors.

Integrated PE-XC underfloor heating kits are becoming increasingly popular in multi-unit residential buildings, commercial buildings, and energy-efficient homes.

Product Excellence Promotion

PE-XC pipes, with their unique electron beam cross-linked structure, demonstrate exceptional adaptability to extreme environments: in terms of high temperature, nano-modification technology has enabled the temperature resistance limit to exceed 110°C, with a lifespan of 50 years at 95°C; pressure resistance is optimized through a three-dimensional network structure of molecular chains; in terms of cold resistance, the low-temperature impact strength retention rate remains above 90% at -40°C, making it particularly suitable for harsh northern regions.

Product Environmental Friendliness Promotion

PE-XC pipes are produced using electron beam irradiation technology, avoiding the use of chemical crosslinking agents such as peroxides or silanes.

This makes PE-XC the first choice when considering low-emission and low-toxicity building materials, making it more attractive in buildings certified by LEED, BREEAM, and WELL.

Irradiation Service Capacity Expansion

The popularity of electron beam irradiation services is continuously increasing in key areas, making the production of PE-XC more convenient.

BGS Beta-Gamma-Service, IBA, and Sterigenics provide outsourced crosslinking services for pipeline manufacturers in Europe and Asia.

The modular production model enables extrusion companies to outsource the cross-linking step, thereby lowering the capital expenditure threshold and helping companies enter the market.

This production flexibility allows small and medium-sized enterprises to offer PE-XC solutions without the need to own irradiation equipment and technology.

04

Macroeconomic fluctuations

Macroeconomic fluctuations have a significant impact on the PE-XC pipe market.

During periods of economic expansion, the demand in the construction and renovation industries is strong, driving the sales growth of PE-XC pipes; whereas during economic downturns, a slowdown in real estate investment may suppress market demand.

Policy adjustments (such as infrastructure investment) will also change the market landscape, prompting companies to adjust their product structures and competitive strategies.

Enterprises need to enhance their risk resistance capabilities by responding to cyclical fluctuations through technological innovation and diversified.

Product quality varies significantly.

Due to some small and medium-sized manufacturers reducing irradiation doses and using inferior raw materials, the quality issues in the PE-XC pipe market have become prominent, seriously affecting the industry's reputation.

Crosslinking is uneven

Due to the difficulty in controlling the electron beam irradiation process, PE-XC pipes have a risk of uneven cross-linking. However, this potential risk is usually limited to small and medium-sized suppliers.

Threat of substitutes

There are similar PE-Xa or PE-Xb products on the market that have a price advantage. At the same time, with the upgrading of PE-RT products, the gap between them and PE-XC products is becoming smaller and smaller, which poses a significant threat to the development of the PE-XC market.

Insufficient consumer awareness: End users have limited understanding of the performance advantages of PE-XC pipes, resulting in consumers still prioritizing price as the primary selection criterion.

Substitute competition is intense.

The temperature resistance performance of PE-RT Type II pipes has been improved to 82℃, with prices 25% lower than PE-XC, creating strong competition.

Supply constraints and risks of raw materials

The import dependency of high-end polyethylene materials reaches 45%, and it is greatly affected by fluctuations in international oil prices. If upstream raw material prices rise or are affected by geopolitical factors, the production or profitability of enterprises will be impacted.

Cross-linked Infrastructure Limited

Electron beam crosslinking requires specialized irradiation facilities, and many emerging markets lack local irradiation equipment and service providers.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track