One Device Equals Five Traditional Sorting Machines? Jiexun Optoelectronics Live Broadcast Unveils AI Quality Selection Superintelligence

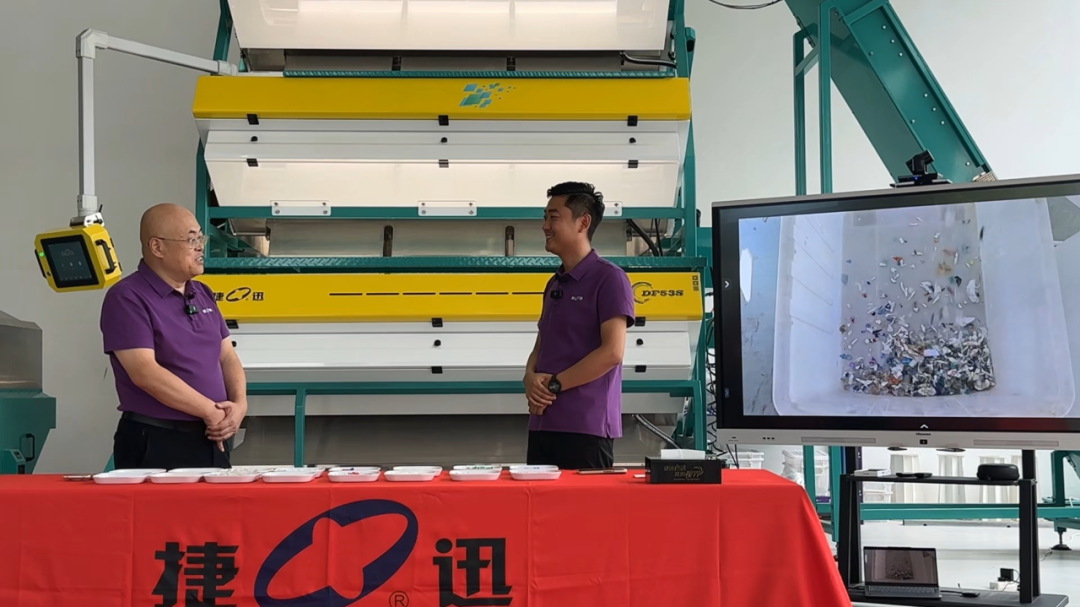

Recently, a live event focusing on renewable resource sorting technology—“The First AI Quality Sorting Superintelligence Is Coming Soon”—was successfully held.This live broadcast features Wang Qi, Director of the Recycling Resource Production Line at Anhui Jiexun Optoelectronic Technology Co., Ltd., and Wang Wang, Executive Vice President of the Plastic Recycling Branch of the China Synthetic Resin Association, as guests. They conducted an in-depth discussion on the "First AI Quality Sorting Super Intelligence," unveiling Jiexun Optoelectronic’s technological breakthroughs and industry practices in the field of recycled plastic sorting.

— 1—

Deeply cultivating the sorting industry for 26 years, technological strategic transfer strengthens the foundation for development.

In the live broadcast, Director Wang Qi first introduced the company background: Anhui Jiexun Optoelectronic was established in 1999 and is a global leading provider of all-scenario intelligent sorting solutions. It has mature and professional solutions in the fields of food safety, industrial manufacturing, and renewable resources, with products distributed in more than 100 countries and regions worldwide.

He emphasized that the company firmly believes that "deep cultivation can improve sorting efficiency" and completed a technical strategy shift a few years ago, comprehensively enhancing its reserves in equipment development and sales teams. This adjustment has proven to be significantly effective, with the number of mid-to-high-end clients using its equipment increasing substantially over the past two years. The company's exposure in the mid-to-high-end market continues to rise, laying a solid foundation for the restart and upgrade of the renewable resources business.

— 2 —

AI Quality Selection Superintelligent Agent: Restructuring the Efficiency of Recycled Plastic Sorting

As the core highlight of this livestream, Wang Qi provided a detailed explanation of the company’s blockbuster product —AI Quality Selection Super Intelligence SystemThe curiosity of the industry about "superintelligent entities" has been addressed.

"Core of 'Quality Selection': Breakthrough in both color and material dimensions."

The "Quality Selection" concept is the core competitiveness of the system, encompassing two main directions: color quality selection and material quality selection. The color quality selection is based on in-depth market research to accurately match industry needs, while the material quality selection covers multiple fields including PP, PE, and fluorescent aging. The system can sort 3-6 types of finished products in one go, avoiding the time and financial waste caused by traditional multiple sorting processes, while reducing the number of sorting equipment and significantly improving sorting efficiency.

Customized + Energy-saving and Efficiency-enhancing to Create a "Small but Excellent" Sorting Solution

The AI Quality Selection Super Intelligent System possesses an exceptionally strong customization capability, allowing it to tailor sorting functions such as color, material, size, whiteness, and fluorescent aging according to customer requirements. It is especially adept at accurately removing black plastic impurities. The system excels in spatial and energy consumption optimization: 5-6 combined units occupy a small area, reduce the use of elevators, and "one unit can replace two or even three units," significantly reducing space and energy consumption, thereby achieving energy conservation, cost reduction, quality improvement, and efficiency enhancement.

Market validation: Deployment of 40-50 units, customer repurchase demonstrates strength.

It is reported that currently, there are already 40 to 50 sets of AI quality selection super-intelligent systems on the market, with some customers purchasing as many as four to five sets individually. Application scenarios cover sorting fields such as PET, HDPE, and mixed plastics. An Anhui customer has repeatedly purchased nearly 20 units of the same equipment from last year to this year, applied to two production lines for PP, PE, and PET. A Shandong customer, after using the equipment, reported that it can accurately remove small black spots. High-end particle sorting equipment has also been purchased in multiple units by an Iranian customer, whose repeated purchases have confirmed the product quality.

— 3 —

Technological Innovation: Eagle Eye 4.0 Achieves 99.99% Sorting Accuracy

During the live broadcast, Wang Qi highlighted the core technological breakthrough of Jiexun Optoelectronics.Hawkeye 4.0 CameraThis bionic recognition device, specially developed for the renewable resources industry, has evolved from version 1.0 to 4.0. Adopting the bionic eagle-eye recognition principle, it offers the advantages of a wider field of view and fewer blind spots.

Through the combination of positive and negative selection, as well as the integration of single-sided and double-sided technology, the Eagle Eye 4.0 camera achieves high-precision recognition. In scenarios such as aluminum bottle sorting, it attains a residual aluminum-free piece recognition rate as high as 99.99% in a single identification, far surpassing the 50% recognition rate of traditional equipment. This technology effectively solves the challenge of recognizing the curvature of bottle pieces and provides a solid technical foundation for color and material sorting.

— 4 —

Focusing on all-material sorting and cost reduction efficiency

Wang Qi candidly stated that the industry's ultimate goal is "to have one machine sort all materials," but it currently faces challenges such as limited spectral bands and high manufacturing costs. Therefore, at this stage, Jiexun Optoelectronics is focusing on the development of customized 2D, 3D, and 4D material sorting machines, aiming to control costs through overall system design—for example, using only one elevator for five color sorters, thus avoiding the high costs associated with connecting individual machines in series.

Meanwhile, the Jiexun team is advancing the research and development of "visible and non-visible integration," planning to apply the eagle-eye camera technology to more scenarios such as barrier agent screen sorting. Currently, the results have shown improvements over competitors, and they will continue to break through technical bottlenecks in the future.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track