Northwestern University Invents Biomimetic Artificial Muscles Enabling Robot Limbs to Push, Lift, and Kick

In the near future, robots may soon possess much greater muscle strength. According to foreign media reports, engineers at Northwestern University have developed a soft artificial muscle, paving the way for untethered animal and human-like robots. This new type of muscle, also known as an actuator, provides the performance and mechanical characteristics needed to build robotic musculoskeletal systems.

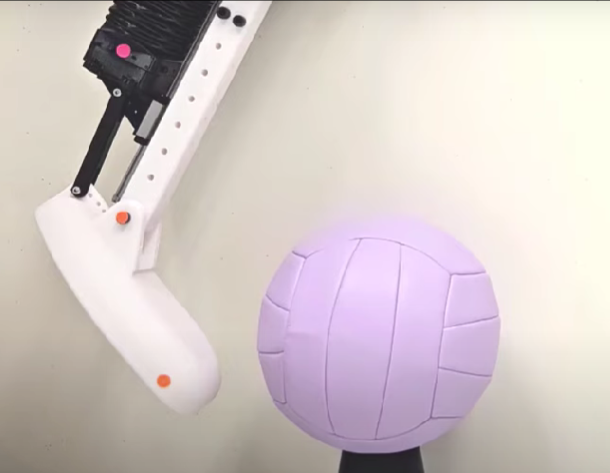

Image source: Northwest University

To demonstrate the functionality of these artificial muscles, engineers implanted them into a life-sized human leg model, equipped with rigid plastic "bones," elastic "tendons," and even a sensor that allows the robot to "sense" its own movements. The leg uses three artificial muscles—the quadriceps, hamstrings, and calf muscles—to flex the knee and ankle joints. These muscles are flexible enough to absorb impact, yet still exert sufficient force and motion to kick a volleyball off its stand.

This new bionic material innovation could change the way robots walk, run, interact with humans, and navigate the surrounding world. The related research paper was published in the journal "Advanced Materials" on July 24th.

"Robots are typically made of rigid materials and mechanical devices that can precisely carry out specific tasks," said Ryan Truby, senior author of the study from Northwestern University. "But the real world is ever-changing and extremely complex. Our goal is to construct bio-inspired robotic bodies that are flexible, adaptable, and capable of handling the uncertainties of the physical world."

This not only includes incorporating practical artificial muscles, but also integrating components such as bones, tendons, or ligaments into robots. If we can achieve this, robots will not only become more resilient and adaptable but also improve efficiency by leveraging the mechanical principles of softer materials.

Copy the current challenges of muscles

At present, most robots are rigid and cumbersome, making it difficult for them to smoothly adapt to uneven terrain or to perform complex and delicate tasks without damaging other objects or injuring themselves.

"It is very challenging for robots that lack physical compliance to smoothly respond or adapt to external changes and interact safely with humans," said Dr. Kim, a postdoctoral researcher at the Truby Lab. "To enable future robots to move more naturally and safely in unstructured environments, we need to design them more like the human body—with both hard skeletons and soft, muscle-like actuators."

Recently, robotics experts have started developing soft actuators with muscle-like mechanical properties. However, current methods typically require large and heavy equipment to drive them. Even so, they are not durable enough to generate sufficient force to accomplish practical tasks.

"Designing soft materials that work like muscles is really difficult," Truby said. "Even if you can make a material move like artificial muscles, there are many other challenges, such as delivering enough power to exert sufficient force. Connecting them to rigid structures similar to bones poses even more problems."

Manufacturing artificial muscles

To overcome these challenges, the team referred to an actuator previously developed by the Truby Lab. The core of this actuator is a 3D-printed cylindrical structure called a "chiral shear auxetic" (HSA). The HSA has a complex structure capable of achieving unique movements and characteristics, such as stretching and expanding when twisted.

The twisting motion required to move the HSA can be generated by a small integrated motor. Kim developed a method to 3D print the HSA using inexpensive rubber commonly found in phone cases.

In the new design, the team encapsulates the HSA in a rubber origami bellows structure, allowing the rotary motor to drive the assembled actuator to extend and retract. Now, these actuators can push and pull with astonishing force, much like artificial muscles. These muscles can even dynamically stiffen under load, just like human muscles.

Each muscle weighs approximately the same as a football, slightly larger than a can of soda. It can stretch to 30% of its length, contract, and lift objects 17 times its own weight. Perhaps most crucial for their application in robots, these muscles can be powered by batteries without the need for bulky external devices.

A life-sized leg that can "kick" and "sense"

To demonstrate the practical application potential of these muscles, Truby, Kim, and their team used 3D printing technology to create a life-sized robotic leg. The team made the "bones" of the leg from hard plastic and used rubber to create connectors similar to tendons. The elastic tendons connect the quadriceps and hamstring muscles to the lower leg bones and connect the calf muscles to the foot structure. The tendons and muscles help to dampen motion and absorb impact, similar to a biological musculoskeletal system.

The team also added a flexible 3D-printed sensor that enables the leg to "sense" its own muscles. The sensor is designed in a sandwich structure, with a layer of flexible conductive plastic sandwiched between two non-conductive layers. When the artificial muscle moves, the sensor moves as well. As it stretches, its resistance changes, allowing the robot to sense the degree of extension or contraction of its muscles.

The final prosthesis is compact in structure and powered by a battery. A portable battery can provide enough energy on a single charge to bend the knee thousands of times within an hour. Achieving similar functionality using other soft actuator technologies would be very difficult, if not impractical.

“By designing new robotic materials with the performance and characteristics of biological musculoskeletal systems, we can create more resilient and durable robots to meet practical usage demands,” said Truby. “We are very much looking forward to seeing how these artificial muscles will drive new directions for humanoid and animal-like robots.”

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track