New Regulations for "Little E-Scooters" Focus on Safety and Plastic Reduction: Impacts and Opportunities for the Plastics Industry

Specialized Plastic VisionOn September 1, it was announced that the mandatory national standard "Technical Specifications for the Safety of Electric Bicycles" (GB 17761—2024), jointly revised by the Ministry of Industry and Information Technology, the Ministry of Public Security, the Ministry of Emergency Management, the State Administration for Market Regulation, and the National Fire and Rescue Administration, has officially come into effect today!

Regarding the current topic of electric bicycle safety, which has been frequently reported in the news this year, just recently on the streets of Kunming, an electric bicycle with an exaggerated design...An "alien"-modified electric vehicle was seized on the spot by law enforcement officers. The entire vehicle was fitted with bionic limb-shaped parts, making the original appearance of the vehicle almost unrecognizable. This not only violates exterior regulations but also poses a driving safety risk due to the altered center of gravity. Law enforcement officers from the Kunming Public Security Bureau Traffic Management Detachment seized the illegally modified vehicle on site, ordered the shop to cease modifications, and required rectification within a specified period.

Source of image: Global Times

To improve range or speed, or to seek excitement or attract attention, illegal modifications of electric bicycles remain rampant despite repeated bans. In response to such chaos, the government has already..."The move has been made," and at the same time, what impact will it have on the plastics industry? Zhuansu Shijie analyzes this here.

"Safety" becomes an unbearable burden for electric bicycles.

At present, the electric bicycle market is booming, with sales continuously rising, making it the preferred choice for convenient travel among many consumers. However, behind this prosperous scene lies significant safety hazards, and the safety issues of electric bicycles have become urgent and must be addressed immediately.

According to relevant statistics,In 2024, there were 473,000 traffic accidents nationwide caused by electric vehicles, resulting in 6,280 deaths and economic losses exceeding 1.8 billion yuan. Illegal modifications, unlicensed vehicles on the road, running red lights, overloading, and riding on highways are frequent violations involving electric vehicles.。Modifying electric vehicles is not only illegal but also greatly increases driving risks and can even lead to tragic accidents causing vehicle damage and loss of life. For example, modifications can change the overall weight of the vehicle, affecting handling and braking performance. Removing speed limits and driving at excessive speeds can easily result in skidding, overturning, and other loss-of-control incidents. Two students in Taojiang, Hunan, were riding a modified vehicle that could reach speeds of...An electric bicycle traveling at 100 km/h crashed into a wall after just 40 seconds on the road, resulting in a tragic death—an unfortunate example.

At the same time, modifications to the wiring and battery retrofitting also pose significant risks. Such modifications are often accompanied by electrical circuit alterations; if the original wiring is subjected to excessive current, it can lead to circuit instability, making short circuits and spontaneous combustion likely during charging or driving. Adding extra batteries may extend the range but forces the motor and other components to operate under overload conditions. It can also cause electrical sparks due to corroded terminals and wire connections, igniting hydrogen gas and leading to explosions.

The new national standard, while improving the anti-tampering requirements for battery packs, controllers, and speed limiters from a technical perspective and comprehensively upgrading safety technical specifications, also introduces...The "rapid power cutoff" mechanism, among others, provides a strong means to curb illegal modifications. However, solving safety issues cannot rely solely on new regulations; consumers must also enhance their safety awareness, refrain from illegal modifications, and choose vehicles that meet standards, have CCC certification, and product qualification certificates. The safety of electric bicycles concerns everyone's life and property and must be taken seriously. Immediate action is required to jointly create a safe travel environment.

“Plastic reduction regulations”Or constrain the demand for plastic products?

ZhuanSu Vision found thatIn the new regulationsThe regulation that "the total mass of plastics used in electric bicycles should not exceed 5.5% of the entire vehicle's mass" is akin to a "tight binding spell" for plastic components. Taking a 63kg lead-acid battery electric bicycle as an example, the weight of plastic parts cannot exceed 3.465kg, which is more than a 60% reduction compared to the current standard. This means that the application space for plastics in electric bicycles is significantly compressed, posing a huge challenge to the plastics industry.

The image is generated by AI.

To comply with the new regulations, companies are adjusting their strategies. A technical director from a manufacturer stated that in order to meet the requirements for plastic parts, they had no choice but to cut...70% of the decorative parts have led to a major change in the vehicle's exterior appearance. Enterprises have increased R&D investment and launched technological competitions. Yadea invested 200 million yuan in developing magnesium alloy frames, Ninebot jointly developed hydrogen fuel cell vehicles with Segway, while small and medium-sized brands, limited by funds and technology, adopted steel-aluminum hybrid frames to reduce costs, sacrificing aesthetics.

In material selection, companies often consider using metal materials to replace plastics to ensure safety, but in the long run, plastics for electric bicycles in vehicles may trigger a wave of innovation.The trend of “replacing steel with plastics”: Different plastic materials each have their own advantages. ABS has good mechanical strength and impact resistance, and is often used for instrument housings and other components; PP is heat-resistant, chemically resistant, and low in cost. After being reinforced and modified, it can be used for frames and similar parts; PC has high transparency, good impact resistance, and heat resistance, making it suitable for lamp covers and similar uses; PA, PBT, PE, and other plastics also play roles in various components.

Production processes have also undergone transformation. Integrated die-casting technology reduces the number of components and improves production efficiency, but requires significant investment in equipment. This drives the industry toward consolidation, with large enterprises set to dominate.

Under the new regulations, the safety performance of electric bicycles has been greatly improved, with features such as BeiDou positioning, fire resistance, and shorter braking distances.“Life-saving equipment” safeguards travel safety. For the plastics industry, although challenges exist, there are also opportunities. With technological advancements, high-performance lightweight plastic materials are expected to play a greater role in the electric bicycle industry, driving the sector toward safer, smarter, and more environmentally friendly development, and providing consumers with a higher-quality travel experience.

"One Helmet, One Wear" - Plastic Helmets Become the Unsung Winner

As the electric bicycle market flourishes and safety requirements become increasingly stringent, Zhuansu Vision has observed that the helmet market—an essential accessory in the electric bicycle sector—is experiencing a significant boom in popularity. This trend is closely linked with plastic materials, opening up new blue ocean opportunities for many enterprises.

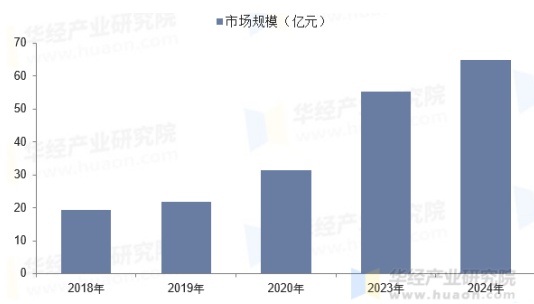

Source: Huajing Industry Research Institute

In recent years, the scale of China's helmet market has grown significantly.The figure soared from 1.276 billion yuan in 2015 to 6.5 billion yuan in 2024, with production surpassing 80.1 million units. Behind this growth are the rise of the food delivery economy and the active promotion of the "One Helmet, One Belt" safety campaign. By the end of 2024, the number of online food delivery users in China had reached 545 million, and the number of electric bicycles in use nationwide stood at 400 million. Policies requiring riders to wear safety helmets have greatly stimulated demand in the helmet market.

In helmet manufacturing, plastic materials are crucial. Regarding shell materials,ABS plastic is impact-resistant, wear-resistant, and low-cost, making it widely used in mid- to low-end helmets and suitable for daily commuting. PC plastic is lightweight and highly impact-resistant, favored in high-end helmets for complex road conditions. Carbon fiber composites have only one-third the density of traditional materials and offer over 40% higher impact strength, making them the top choice for high-end helmets and almost standard in racing, extreme sports, and other high-risk areas. Fiberglass has relatively high strength but is more brittle, and is mostly used in entry-level sports helmets.

Buffer layer materials also rely on plastics.EPS foam polystyrene is lightweight and has excellent cushioning performance, making it a popular choice for the padding layer in mass-market helmets; EPP foam polypropylene offers outstanding cushioning and good resilience, suitable for riders with higher safety requirements. Additionally, the helmet lining and accessories feature soft fabrics and sponges to enhance comfort, PC material is used for the visor to ensure clear vision, and the fastening system consists of nylon straps and plastic buckles.

The booming helmet industry has attracted numerous enterprises from both upstream and downstream of the supply chain. Among upstream raw material companies, Kingfa Sci & Tech, as a leading modified plastics manufacturer in China, is actively expanding into international markets, with overseas base expansions helping to increase its market share. Companies such as Wote New Materials and Polyrocks Chemical are also important suppliers of specialized helmet materials and equipment solutions, providing the helmet industry with a diversified selection of materials.

Among midstream manufacturers, Pengcheng Helmets has an annual production exceedingWith 3 million units produced, products exported to over 100 countries, and its brand LS2 sponsoring multiple international events, it has strong competitiveness in the international market. Foshan Wenjin owns several helmet brands, with products certified by multiple international standards, focusing on design and technological innovation. Chengxiang Emergency Equipment specializes in the research and production of firefighting helmets, launching a full range of carbon fiber firefighting helmets equipped with various intelligent functions, leading in the special helmet field. In addition, well-known brands such as Eternal Helmet YOHE and SHOEI also have comprehensive systems, with products covering multiple fields.

Although Tosta has the capability to provide a full set of helmet production line solutions among equipment suppliers, it faces intense competition and declining revenue. However, overall, the boom in the helmet market has brought unprecedented opportunities to plastic materials and related companies. With the continuous growth of market demand, the industry outlook is very promising, and companies will continue to promote the development of the helmet industry towards higher quality under the safety-first concept.

Source: Baidu Youjia

Epilogue:

With the implementation of the new national standards for electric bicycles, the entire industry is undergoing profound changes. From improvements in vehicle safety performance to challenges faced by the plastics industry, and the booming helmet market, all highlight the power of safety and regulation. Under the new regulations, opportunities and challenges coexist. Whether it is electric bicycle manufacturers, plastics companies, or various parties in the helmet industry chain, all must keep pace with the times, drive development through innovation, and jointly promote the industry towards a more prosperous and sustainable future while ensuring safety.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track