Must-see at the composite expo: What High-Performance New Products Has BYK Brought?

On September 16, the China International Composites Expo grandly opened at the National Exhibition and Convention Center in Shanghai. As one of the leading suppliers in the field of global additives and measuring instruments, what new products did BYK Chemie showcase with its impressive presence?

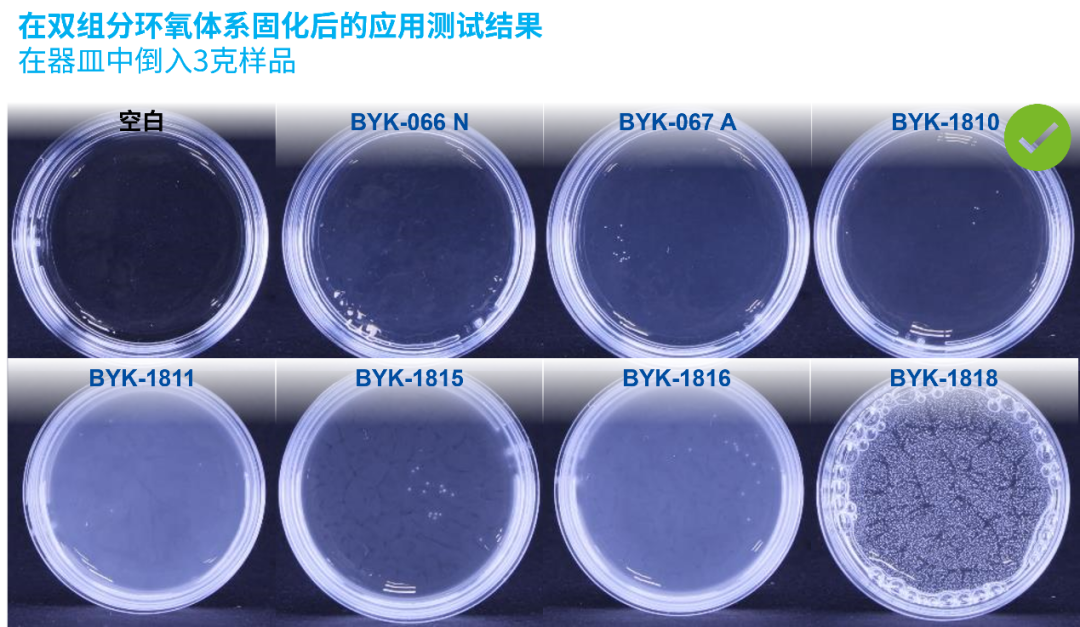

1. BYK-1810, BYK-1815Silicone defoamer without PFAS, suitable for solvent-based and solvent-free systems.

Perfluoroalkyl and polyfluoroalkyl substances (PFAS) are widely used in everyday products such as non-stick coatings, firefighting foams, and paints. However, PFAS are currently suspected of being potentially harmful to health, which is why their use is increasingly restricted worldwide.

These two new defoamers have highly efficient and outstanding spontaneous defoaming performance, achieving spontaneous defoaming even at low dosage. They are completely fluorine-free, yet their defoaming effect is comparable to PFAS-containing products. This series of additives can be used in various solvent-based and solvent-free systems, with a wide range of applications.

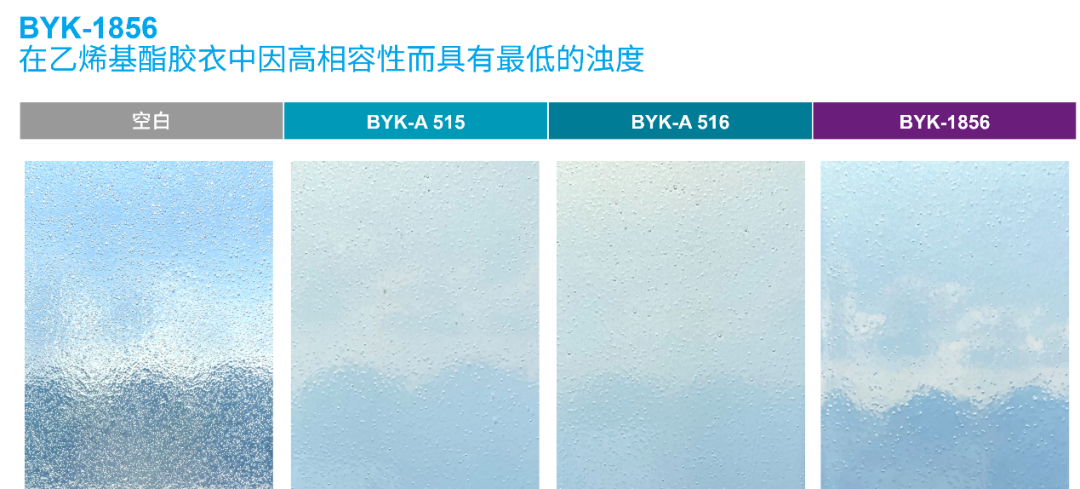

2. BYK-1856 is a silicone-free, aromatic-free defoamer with excellent defoaming performance and outstanding compatibility.

In many application scenarios, defoamers need to achieve high-efficiency defoaming performance while maintaining good compatibility, which seems difficult to achieve simultaneously. However, BYK-1856 utilizes advanced acrylic technology to successfully balance this contradiction, perfectly integrating efficient defoaming with excellent compatibility. This defoamer is particularly suitable for systems that require strict compatibility and outstanding defoaming effects. It is not only applicable to two-component epoxy and two-component polyurethane coatings but also suitable for common thermosetting systems such as epoxy, unsaturated polyester, vinyl ester resins, and low molecular weight acrylic slurries.

3. BYK-081 Fluorine-Free, Highly Transparent Defoamer

BYK-081 is suitable for solvent-based and amine-neutralized, water-reducible systems. This additive replaces the previous BYK-80 A, achieving good surface tension reduction even without using fluorine-containing components. Due to its good compatibility, BYK-081 can be used in UP systems, epoxy resin systems, and polyurethane systems, especially for transparent applications. Additionally, it is also suitable for internationally recognized food contact applications.

Advantages of BYK-081

Fluoride-free

Internationally recognized food contact applications: According to the U.S. Food and Drug Administration 175.300, EU PIM (EC) 10/201, China GB 9685-2008, etc.

·Excellent spontaneous defoaming effect

Significantly reduces surface tension, provides good substrate wettability, and is pinhole-free.

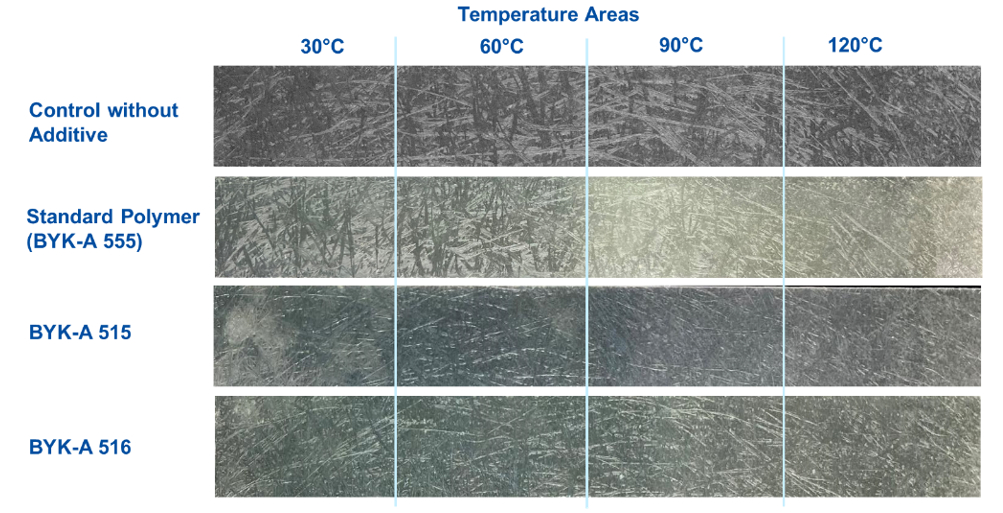

4. BYK-A 516 is a non-silicone, non-aromatic polymer-based defoamer suitable for thermosetting applications and improving glass fiber wetting.

BYK-A 516 is a universal, high surface activity defoamer. In fiber composite applications of unsaturated polyester resins and vinyl ester resins, it not only effectively defoams but also offers fiberglass wetting properties. Particularly in vinyl ester resin applications, BYK-A 516 does not cause the whitening phenomenon common with conventional defoamers. This defoamer is widely applicable, including room temperature curing resin systems based on unsaturated polyester resins, vinyl ester resins, acrylic resins, epoxy resins, and polyurethane resins, as well as pultrusion systems based on acrylic resins, unsaturated polyester resins, or vinyl ester resins.

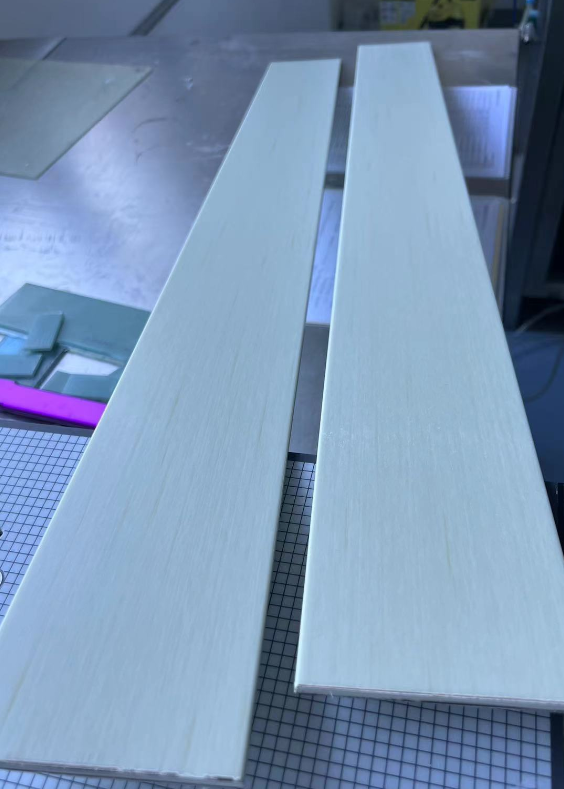

5. BYK-P 9912 is a processing additive with internal mold release functionality, enabling the wind power pultrusion beams to be free from grinding.

Under the current process conditions, removing the release fabric without treating the surface of the beam will affect the interface bonding performance between the subsequent beam panel and the infused resin. BYK-P 9912 is a processing additive with internal release function that allows for direct infusion bonding without grinding the product, and its performance at the interface has been recognized by pultrusion companies.

BYK-P 9912 is a modified hyperbranched polymer where low-polarity groups, which are incompatible with the resin, are distributed at the interface between the resin and the mold to achieve demolding functionality. Meanwhile, the moderately polar main chain and highly polar groups, which have certain compatibility with the resin, enable better compatibility with the resin and can form chemical bonding forces with it. Under the dual effects of hyperbranched physical anchoring and chemical bonding forces, it can be firmly locked within the resin system without secondary migration.

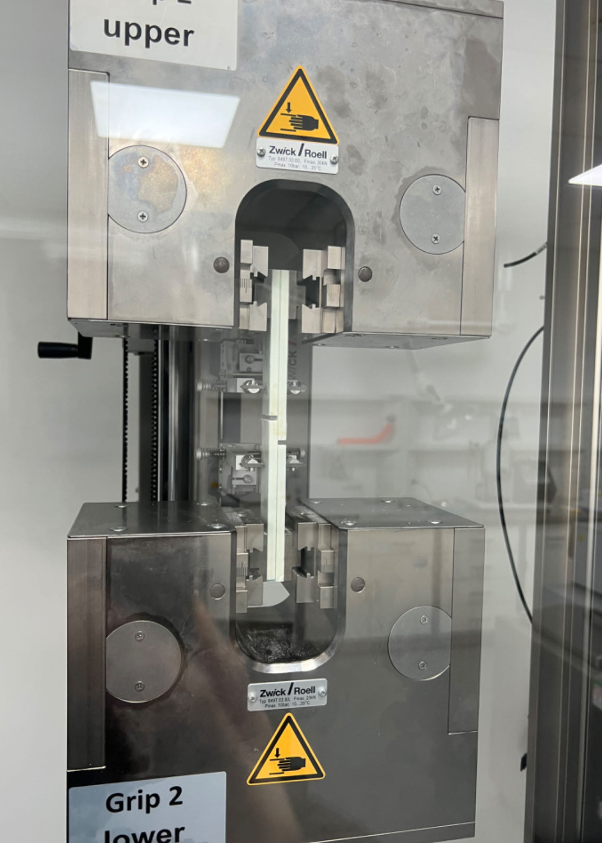

Pultrusion sample

Single lap shear strength test

Advantages of BYK-P 9912

Does not participate in the chemical reaction of the resin system, remains stable without stratification, and can exist stably for a long time when mixed with the resin system.

Do not reduce the interfacial bonding strength between the resin and the fibers.

With a small addition amount and low overall cost, dynamic and static continuous demolding can be achieved.

It has both defoaming properties and reduces voids in the product, improving quality.

Can achieve a no-grinding process, eliminating the dust and wastewater produced by grinding, which is friendly to operators and the environment.

6. BYK-P 9920 Processing Aid for Improving the Wetting Performance of Glass Fiber/Carbon Fiber

This is a multifunctional additive with both defoaming and wetting effects. When added in small amounts, it can reduce the viscosity of epoxy resin and polyurethane on one hand, and effectively lower the surface tension of the system on the other. This accelerates the spreading of the resin on the fiber surface, i.e., reducing the contact angle, thereby further enhancing the resin's wetting of the fibers and eliminating defects such as dry fibers and voids in the product caused by poor wetting.

Add BYK-P 9920

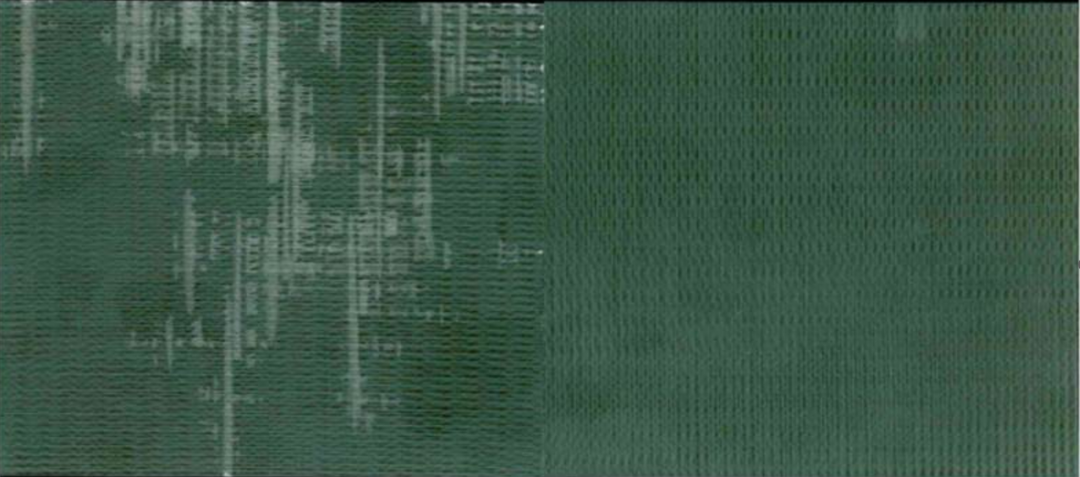

BYK-P 9920 also has a significant effect on solving the fiber impregnation problem of large tow carbon fiber pultruded beams. Due to the strong bundling of large tow carbon fibers like 24K, 48K, 50K, and their smaller fiber diameter compared to glass fibers, it is challenging to achieve good impregnation between the bundles, especially within the bundles, in a short time while maintaining a reasonable production pace. By adding BYK-P 9920, the impregnation problem of large tow carbon fibers can be significantly resolved, improving product yield and reducing overall costs, making it the preferred additive product for carbon fiber pultrusion companies.

Add BYK-P 9920

7. BYK-P 9929 Processing Additive for Reducing Exothermic Peaks in Free Radical Curing Systems

The free radical polymerization of unsaturated polyester and vinyl ester resins is typically a distinctly exothermic reaction, releasing energy that can result in extremely high temperatures. Excessive temperatures may cause the polymer to warp, become brittle, crack, or even undergo thermal decomposition. Therefore, we have developed a processing aid that reduces the exothermic peak without compromising other properties.

Cracking due to excessive temperature

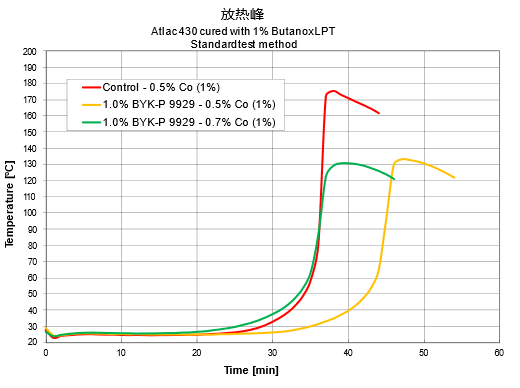

1/The effect in vinyl resin systems.

Adding 1% BYK-P 9929 reduces the exothermic peak from 176°C to 133°C. The delay in curing time can be mitigated by adding 0.2% cobalt accelerator, without increasing the exothermic peak.

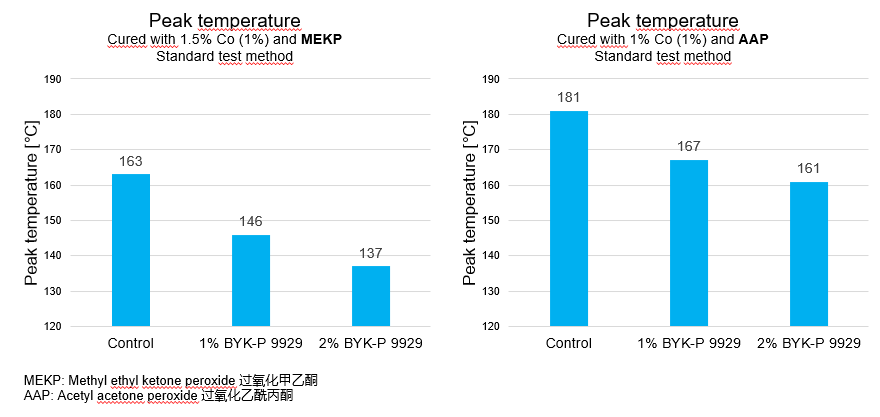

2/The effect in ortho-unsaturated polyester

BYK-P 9929 can reduce the exothermic peak of cobalt-promoted resin systems using different peroxide curing agents.

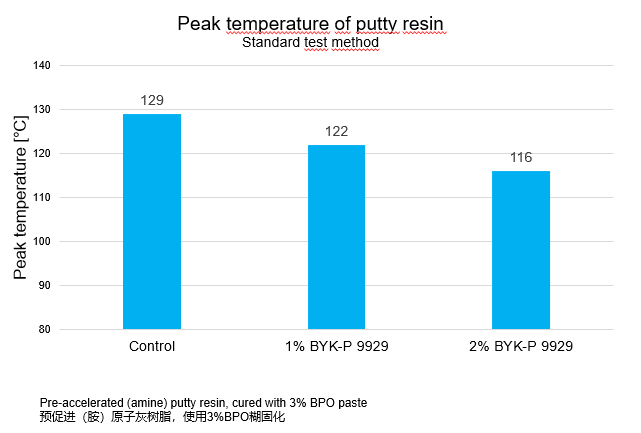

3/The effect of BYK-P 9929 in amine-promoted BPO curing systems.

BYK-P 9929 reduces the exothermic peak of the amine accelerator system in polyester putty resin.

BYK-P 9929 not only can reduce the exothermic peak of the system, but also has many excellent performances, including minimal impact on mechanical properties, no effect on product curing, easy mixing of the liquid, and stable storage in resin.

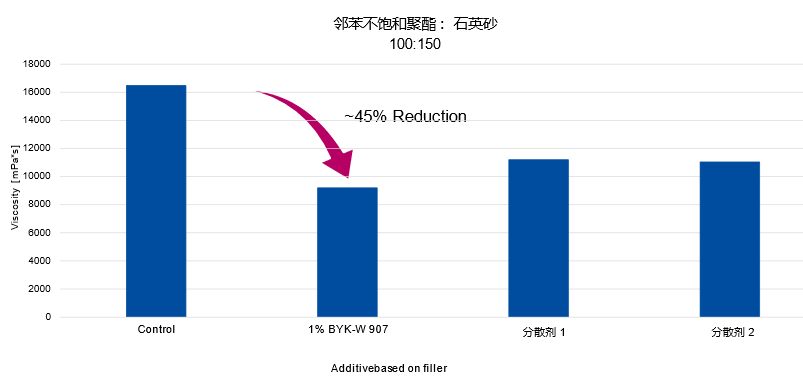

8. BYK-W 907 is especially suitable as a wetting and dispersing agent for engineered stone (artificial stone).

In the formulation of engineered stone materials, a high filler content is required, and the material must be molded through compaction and other methods. To improve the surface quality of the product and reduce adverse effects such as voids, dry cracks, and microcracks, the wetting and dispersing agent BYK-W 907 can be added. This dispersing agent can reduce the liquid phase component and lower the raw material cost without affecting the mechanical properties of the final product.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics