Modified plastics' three golden tracks: Which Will Explode First - Robotics, AI, or Automotive?

The modified plastics industry is ushering in a new wave of development opportunities. Driven by demand from emerging downstream fields, advancements in high-end material technology, and increased penetration rates, the industry is experiencing a sustained upward trend. CITIC Securities has identified three major hot directions: PEEK for robotics; high-frequency, high-speed resin materials for PCB substrates in computing power; and materials benefiting from automotive material technology.

The three major directions not only represent the areas with the greatest growth potential in the modified plastics industry in the future but also reflect the trend of deep integration between new material technologies and emerging downstream industries. Below, Specialized Plastics Vision will conduct an in-depth analysis from the perspectives of material categories and manufacturer layout in these three fields.

1. The demand for lightweight robots is driving the special engineering plastics market.

The humanoid robot industry is developing at an astonishing speed, with lightweight design being one of the major trends for the future, creating a vast market space for special engineering plastics. According to estimates by CITIC Securities, based on the Tesla Optimus production ramp-up, if Tesla Optimus reaches an annual shipment volume of 300,000 units by 2028, the global additional demand for PEEK will reach 3,000 tons, and the new market size is expected to exceed 700 million yuan. Considering that many global tech giants are entering the humanoid robot field, the actual market size could far exceed this forecast.

PEEK(Polyether ether ketone) specialty engineering plasticPEEK is the most prominently driven plastic category after the humanoid robot industry gained traction. It has advantages such as high strength, high elastic modulus, high vibration damping, and low density, making it an ideal material for achieving lightweight robots. As the domestic substitution of upstream raw materials accelerates and production capacity continues to expand, leading to cost reductions, PEEK materials are rapidly penetrating into core components of humanoid robots such as joint bearings and gears. In fact, not only PEEK but also various other types of plastics have huge application potential in humanoid robots.

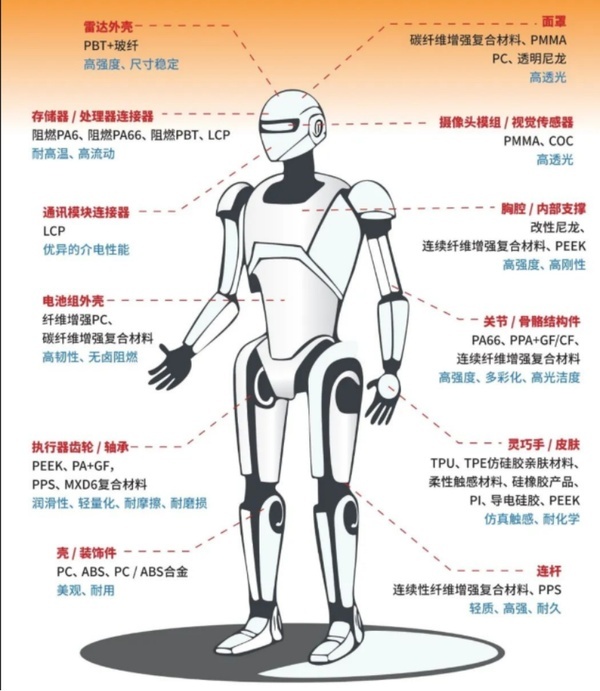

1Key Material Categories and Application Scenarios

In humanoid robot manufacturing, different parts have varying requirements for material properties, leading to a diverse range of modified plastic solutions.

Joint partsPEEK and its modified materials, with their extremely high rigidity and wear resistance, as well as significant lightweight benefits (density much lower than metals), have become the material of choice for joint components. Their high rigidity ensures precise movement and stability of the joints, while their excellent wear resistance extends the lifespan of the joints.

Structural components and skeletonCarbon fiber reinforced nylon materials (such as PA-GF) and "good appearance high-strength continuous fiber reinforced polyamide" (LFT-PA) solutions have achieved a balance of lightweight and rigidity by "replacing steel with plastic". These materials can replace some metal components in the structures of robotic arms and frameworks, reducing weight while maintaining strength.

Shell and SkinPC/ABS, ABS, and other lightweight plastic solutions are used for enclosures; TPE (thermoplastic elastomer) materials are used to simulate the tactile experience of human skin, enhancing the friendliness of human-computer interaction.

Image source: CHINAPLAS 2025

2. Latest Developments in Manufacturers' Layout

Domestic modified plastics companies have keenly seized the opportunities in the humanoid robot industry, and have increased their investment in research and development as well as capacity planning.

Golden Hair TechnologyA specialized research and development team for humanoid robot materials has been established, and collaborations have been initiated with manufacturers such as Unitree Robotics, Yunshenchu, and Zhiyuan Robotics for joint development. Some customers have already achieved bulk supply. The materials developed by the company, such as PEEK, polyamide, and LCP, can be applied to the key components of humanoid robots. It is worth mentioning that Kingfa Sci & Tech has also strengthened its industrial chain coordination by holding less than 1% equity in Unitree Robotics.

PrittIn June 2024, an investment of 1 billion yuan was announced to establish Guangdong Polymtek New Materials Co., Ltd., to build a research and manufacturing base for modified materials. The second phase of this project will focus on producing modified PEEK, modified PPS, liquid crystal polymers (LCP), and carbon fiber reinforced materials for application in the humanoid robot field.

Wote CorporationLiquid crystal polymer (LCP) materials, special nylon (PPA) materials, and PEEK materials have all found applications in the robotics industry. Their DuraKraft™ PEEK material has been optimized for joint components, achieving breakthroughs in lightweight, wear resistance, and high-temperature resistance.

Since 2025,Huitong Co., Ltd.Some materials have already been applied to robotic products, and close cooperation is maintained with many companies. The TPE soft rubber material solution developed for robotic hand components is already being marketed. Huitong pioneered the PC ternary alloy material. This material has ultra-high chemical resistance, wide processing moldability, low residual stress performance, and excellent dimensional stability, which can meet the use of humanoid robots in various complex and harsh environments, further broadening the application and adaptability of humanoid robots.

Source of image: Huitong Co., Ltd.

International chemical giants are also accelerating their expansion.

Recently,BASFBASF Venture Capital GmbH has partnered with Shanghai Fourier Intelligence Co., Ltd. to develop next-generation material solutions for humanoid robots, jointly exploring the application of engineering plastics, polyurethane, and thermoplastic polyurethane in robots and their components. This collaboration is initiated by BASF's venture capital division and is its first collaboration project in the Chinese robotics industry.

EnhualiSENTImotion and Fugen Group have collaborated to develop a new robotic arm gearbox solution based on advanced engineering materials. This gearbox solution, named SMFdrives, uses Stanyl from Enval as its core component.®Made of PA46 material. Thanks to the characteristics of polyamide 46 material and low-density design, compared to traditional metal gearboxes, this plastic-based gearbox reduces cost by 50%, reduces weight by 50%, and yet performs just as well. The gearbox designed in this way better meets the requirements for long-term durability, ensuring that various mechanical indicators meet the safety and reliability needs of robots throughout their entire lifecycle.

The new robotic arm gearbox solution lays the foundation for high-cost-efficiency mass production of lightweight, high-energy-efficiency robots (Image source: Enhuari).

2. The Computing Power Revolution Drives the Explosive Demand for High-Frequency and High-Speed Resin Materials

With the explosive growth of artificial intelligence (AI) technology worldwide, its demand for high-performance materials is driving the engineering plastics industry into a new upgrade cycle. From data center liquid cooling systems to autonomous driving sensors, from medical robots to wearable devices, specialty plastics, with their advantages of high-temperature resistance, lightweight, and chemical stability, have become the core support for AI hardware manufacturing.

1Key plastic categories in the field of computing power substrates

In the field of AI chip packaging (such as GPU/TPU),Polyetherimide (PEI)Due to its long-term resistance to temperatures above 170°C, it has become the preferred choice for heat sinks and connectors.

In high-frequency communication scenarios, low dielectric lossPolyphenylene Oxide (PPO) PTFE materialPTFE copper-clad laminates are widely used in 5G millimeter-wave antennas and server backplanes. NVIDIA's released GB300 AI server even uses PTFE copper-clad laminates instead of traditional copper cables to address the heat dissipation challenges at high transmission rates.

As the computing power density of data centers increases and the efficiency requirements for server operation rise, cooling systems have become a core component in ensuring the stable operation of equipment. The current mainstream application scenarios focus on immersion liquid cooling systems, high-speed connectors, and cooling pipelines, which impose stringent requirements on the performance of supporting materials. Various high-performance materials have clearly defined application directions: 40%Glass fiber reinforced polyphenylene sulfide (PPS)With excellent dimensional stability, it has become the preferred choice for liquid cooling tank structures, with the dimensional change rate controlled within 0.2%.Polyether ether ketone (PEEK)Combining the lightweight advantages of carbon fiber composites for making server support frames can achieve a 30% weight reduction.EPDM (Ethylene Propylene Diene Monomer) Rubber Polytetrafluoroethylene (PTFE)Due to its high pressure resistance, it is compatible with sealing components and quick couplings, and can withstand a working pressure of 35 bar.Liquid Crystal Polymer (LCP)The insulating sheet made through the aluminum nitride filling process has a breakdown voltage of up to 40kV/mm, providing reliable insulation protection for key components.

2. Latest Developments in Manufacturer Layout

Golden Hair TechnologyIn the field of AI, a clear technological path and industrialization direction have been established. For example, the SPxx-CGxx and SPxx-EGxx series of thermally conductive plastics from Kingfa Sci & Tech Co., Ltd. feature both electromagnetic shielding and thermal conductivity properties. They have a vertical thermal conductivity coefficient greater than 1.0 W/(m·K) and an electromagnetic shielding effectiveness greater than 40 dB. Additionally, they offer advantages such as high strength, low density, and dimensional stability, making them suitable for key components like router back covers, base station heat dissipation modules, and chip heat sinks.

Image source: Kingfa Sci & Tech

Silver Jubilee TechnologyThe company is actively investing in electronic-grade high-frequency high-speed substrate PPO materials, with the current 300-ton capacity gradually ramping up. Additionally, it has a planned 1,000-ton capacity facility that has already obtained an A-grade chemical engineering qualification. The company's downstream clients include leading enterprises such as Panasonic and Shengyi Technology. It is expected that once the 1,300-ton PPO capacity is scaled up, the company is likely to become a leading supplier nationwide.

Walt CorporationThe SELECTION®LCP materials target precision gear applications, and their excellent high-temperature resistance and high-frequency signal stability can ensure the stable operation of AI servers in complex environments. The company has also developed LCP material solutions specifically for high-frequency connectors.

PrattIn the construction of the South China base, a special plan was made for the production line of Liquid Crystal Polymer (LCP), a material widely used in the fields of 5G and AI servers. The company collaborates strategically with downstream PCB manufacturers to jointly develop composite materials suitable for high-speed transmission.

3. Automotive Lightweighting and Intelligentization Drive Material Innovation

The automotive industry is undergoing a dual transformation of lightweight and intelligent development, creating a huge market space for modified plastics. According to estimates by the research department of CITIC Securities, the domestic demand for automotive modified plastics is expected to reach 10.37/12.40 million tons by 2030/2035, with a CAGR of approximately 8.5% from 2024 to 2035.

1、Key Material Categories and Application Breakthroughs

Innovations in automotive modified plastics mainly focus on the following types of materials:

Image of car interior (Image source: Napan)

Long glass fiber reinforced PP(LGFPP)Compared to short glass fibers, LGFPP has better creep resistance and a density far lower than that of metals, allowing for a weight reduction of 20% to 50% for the same components. It is widely used in automotive front-end modules, dashboard frames, battery brackets, and other parts.

Micro-foamed PP Through micro-foaming processes such as injection foaming and blow molding foaming, microcellular structures of 80-350μm can be achieved in products, reducing the weight of plastic products by 10%-20% and reducing weight by over 50% compared to metal. This is applied in automotive parts such as tailgates, roofs, and air ducts.

Fiber-reinforced PABy adding 20% to 40% glass fiber (GF) to PA66, the resulting PA66/GF composite can achieve a flexural strength of up to 310 MPa, a notched impact strength of approximately 25.4 J/m, and a water absorption rate of only 0.9%. It is commonly used in heat-resistant functional parts such as engine covers and intake manifolds.

Flame-retardant PA6By using a composite flame retardant system of halogen flame retardants and antimony trioxide, the flame retardancy of PA6 reaches the UL94 V-0 level, making it an ideal material for electric vehicle power battery enclosures, brackets, and covers.

Polyphenylene sulfide (PPSMaterialsThe material possesses characteristics such as high temperature resistance (long-term use temperature of 220°C, heat distortion temperature up to 260°C), dimensional stability (low moisture absorption <0.05%), laser friendliness (light transmittance > 35% after special modification), aging resistance (UV resistance, corrosion resistance), and flame retardancy (UL94 V-0). It was previously used mainly in core automotive components, but is now gradually penetrating into special interior and exterior domains. For example, 20% glass fiber reinforced PPS (P201X20) is used for ADAS camera housings, 50% glass fiber reinforced PPS (P201X50) for lamp bases, 65% glass mineral reinforced PPS (P201M65) for HUD brackets, and 40% glass fiber reinforced PPS (P201X40) for central control instrument light guide plates, addressing the performance deficiencies of traditional plastics.

2Manufacturer's Latest Deployment Dynamics

Huitong Co., Ltd.Developed a variety of modified plastic solutions for automotive use, including: PC ternary alloy materials for housing components with ultra-high chemical resistance; carbon fiber reinforced nylon for structural components, achieving "plastic replacing steel"; and modified PEEK materials for joint components to extend service life.

Dawn HoldingsModified materials and elastomer materials have been applied to the field of new energy vehicle manufacturing, including robotic arm nylon materials, alloy materials, etc. The company also showcased a simulated skin material solution, which can be applied to automotive interiors in the future.

Jinfa TechnologyIn the automotive field, material innovations are too numerous to list. For instance, the development of micro-foamed PP materials has been used in the tailgates and interior parts of several new energy vehicle models, reducing weight by more than 15% compared to traditional materials. The PA6 or PET materials developed by Kingfa Sci & Tech for LED car light housings feature high thermal conductivity, with an in-plane thermal conductivity coefficient of over 5W/(m·K) and a vertical thermal conductivity coefficient of over 1W/(m·K), along with a water absorption rate of less than 0.2%. These characteristics are crucial for LED car lights. Additionally, the PA6 or PET materials used for LED car light housings also have adjustable electrical resistance and are easy to mold into complex structures, which has sparked interest among various lighting manufacturers in using thermally conductive plastics.

Napine New MaterialsThrough continuous innovation, PPS, a "high-end material," is enabling high cost-performance applications in the automotive interior and exterior fields, redefining the value standards of interior and exterior materials. Recently, Napalm released three new PPS-based thermoplastic composite products at the "Napalm New Energy Composite Technology Summit and Thermoplastic Composite Product Launch." These products include a thermoplastic composite three-electric end cover (NVH superior to aluminum alloy, EMC over 60dB across the range), a thermoplastic composite underbody shield (tensile strength >400MPa, impact resistance 500J), and a thermoplastic composite battery box cover (weight reduced from 18kg to 6kg, a reduction of up to 67%, with sustained fire resistance).

Figure: Three new PPS-based thermoplastic composite materials (Image source: Napan)

4. The modified plastics industry is ushering inHigh-end==+PlatformizationNew Stage of Development

The modified plastics industry is experiencing unprecedented development opportunities. From a market perspective, the three major hot directions are showing rapid growth: PEEK materials for humanoid robots are set to boom with the mass production of products like Tesla Optimus; driven by the demand for AI servers, the high-frequency high-speed resin market is expected to have a CAGR of 85% over the next three years; automotive modified plastics are maintaining a stable growth of 8.5% under the trends of automotive lightweighting and electrification.

From the perspective of the industrial structure, domestic enterprises are accelerating their advance into the high-end market. Leading companies such as Kingfa Sci & Tech, WOTE, and Polystone are gradually breaking the monopoly of foreign enterprises in the high-end market by building dedicated production capacities, increasing R&D investments, and forming strategic partnerships with downstream companies.

From the perspective of technological trends, the development direction of "high-end and platform-based" is clear. On one hand, high-end materials such as PEEK, LCP, and high-frequency high-speed resins have become the focus of competition. On the other hand, leading companies are transitioning from being single material suppliers to overall solution providers. For instance, Kingfa Science & Technology showcases a comprehensive material solution for humanoid robots, and Huitong Co., Ltd. has launched a set of materials for various parts of automobiles.

Editor: Lily

Sources: CITIC Securities, Plastics Vision, Napatech, Kingfa, JRJ.com.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics