Milestone Upgrade! KraussMaffei Refreshes TPU Production Capacity "Ceiling"

As the pace of industrialization accelerates and the quality of life improves, the global demand for thermoplastic polyurethane (TPU) continues to rise. TPU materials, with their excellent elasticity, wear resistance, and environmental performance, are being widely used in various fields such as footwear, tubing, films, automotive, and medical.

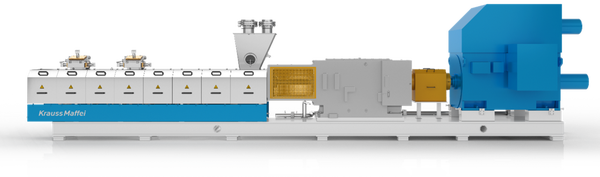

However, one of the core challenges in TPU production lies in capacity and efficiency. Traditional production equipment often struggles to meet the demands of large-scale, high-quality production, leading to capacity bottlenecks and cost pressures for enterprises. Against this backdrop, KraussMaffei launched the Golden Power large and medium-sized twin-screw extruder ZE 145 (hereinafter referred to as ZE 145) in April 2024, with a capacity of up to 4 tons per hour, effectively helping to break through industry capacity constraints.

Recently, the KraussMaffei Golden Power ZE 145 twin-screw extruder has been successfully delivered to a leading domestic polyurethane company and has smoothly passed the customer's acceptance. This milestone not only marks an important breakthrough for KraussMaffei in the TPU production field of the large petrochemical industry, but as the first domestically produced twin-screw extruder with a capacity of 4 tons/hour, the ZE 145 also stands out with its excellent performance and localization advantages, becoming a "super engine" for TPU production in the large petrochemical industry, helping the industry reach new heights.

The success of ZE 145 is inseparable from its strong technical advantages and localized innovation:

1

imported core components, stable and reliable

The key components of ZE 145 adopt internationally renowned brands, ensuring the stability and reliability of the equipment under high-load operation, safeguarding continuous and efficient production.

2

localization of process components, reduce costs

Through the localization of production for process components, ZE 145 significantly reduced equipment manufacturing costs, while also shortening the delivery cycle, allowing customers to enjoy the competitiveness brought by advanced equipment at a better price and faster speed.

3

quick response after-sales, worry-free service

The localized service team provides 24/7 rapid response after-sales maintenance services, minimizing equipment downtime to ensure smooth production and give customers peace of mind.

4

intelligent control, easy operation

ZE 145 is equipped with an advanced intelligent control system, achieving precise control and real-time monitoring of the production process, significantly reducing operational difficulty and improving production efficiency.

The line was delivered to the customer in September 2024, and after several months of installation and debugging, it was successfully put into production, receiving excellent feedback from the customer. The ZE 145 not only helped the customer achieve a significant increase in production capacity but also notably reduced production costs and delivery cycles, truly achieving efficiency, stability, and peace of mind!

This successful delivery and acceptance is not only a victory for the ZE 145, but also an important breakthrough for KraussMaffei in the TPU production field of the large petrochemical industry. The ZE 145 twin-screw extruder, with its advantages of high capacity, high stability, low cost, and intelligent control, is redefining industry standards and helping customers seize market opportunities. KraussMaffei will continue to uphold the spirit of innovation, promote technological progress in the industry, and provide customers with more efficient and reliable solutions.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track