MEAF Showcases Xtender Technology at 2025 Germany K Fair, Two New Devices Boost Recycled Material Quality

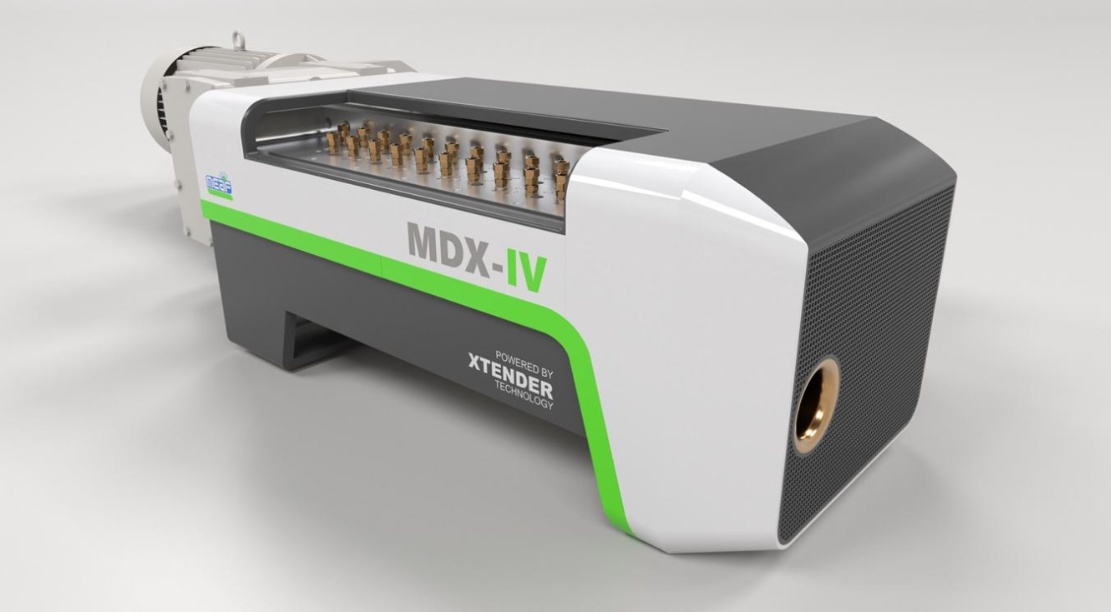

At the 2025 K Fair in Germany (International Plastics and Rubber Exhibition), Dutch manufacturer MEAF Machinery will launch two new equipment series aimed at enhancing the quality of recycled materials—the MDX-IV series and the MDX-DEO series. Both pieces of equipment are based on the company's patented Xtender melt adjustment technology.

MDX-IV Series: Specifically Designed for Recycled PET (rPET) Processing

The MDX-IV series equipment is designed for the purification treatment and intrinsic viscosity (IV value) enhancement of recycled PET (rPET). This functionality can transform low IV value recycled PET materials into higher quality pellets, providing two core values for processing enterprises:

Improved raw material usage flexibilityCan flexibly adapt to recycled materials from different sources without being limited to a single raw material;

Market cost advantages become prominentThe current market often sees the price of virgin resin lower than that of recycled material. This equipment can enhance the quality of low-grade recycled material, helping companies control costs while increasing the proportion of recycled material used.

MDX-DEO Series: Suitable for Other Thermoplastic Plastics

The core functions of the MDX-DEO series are "purification + deodorization" (with "DEO" in the name referring to Deodorization), specifically designed for the upcycling of recycled thermoplastics such as polypropylene (PP), polyethylene (PE), and polystyrene (PS).

This technological breakthrough has opened up new application scenarios for recycled materials, including packaging, films, carpet backing, and automotive interior parts. Previously, the stringent requirements for odor and volatile substance content in these fields had been a key bottleneck limiting the application of recycled materials.

Assist in achieving PPWR goals and sustainable development

The EU Packaging and Packaging Waste Regulation (PPWR) clearly requires that by 2030, the recycled content in PET packaging must reach at least 30%, and the recycled content in other sensitive packaging in contact with products must reach at least 10%.

The MDX series of equipment launched by MEAF Company is focused on helping plastic processing companies achieve the above regulatory goals, while also assisting enterprises in reducing their reliance on virgin materials and lowering their carbon footprint—achieving all of this without compromising product quality or energy efficiency.

Technical Features and Commercialization Plan

Xtender technology has two key advantages:

Excellent Craftsmanship PerformancePossesses excellent mixing and degassing effects, enabling precise control of the quality of recycled material melt.

Wide adaptabilityCan be used as a retrofit component for single-screw and twin-screw extruders, eliminating the need for companies to replace the entire equipment and reducing the cost of technological upgrades.

It is reported that these two new devices will be officially commercialized globally starting in the fourth quarter of 2025.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track