Major Innovation! Ninghua YHIII Pre-Plasticizing Series Injection Molding Machine Newly Launched

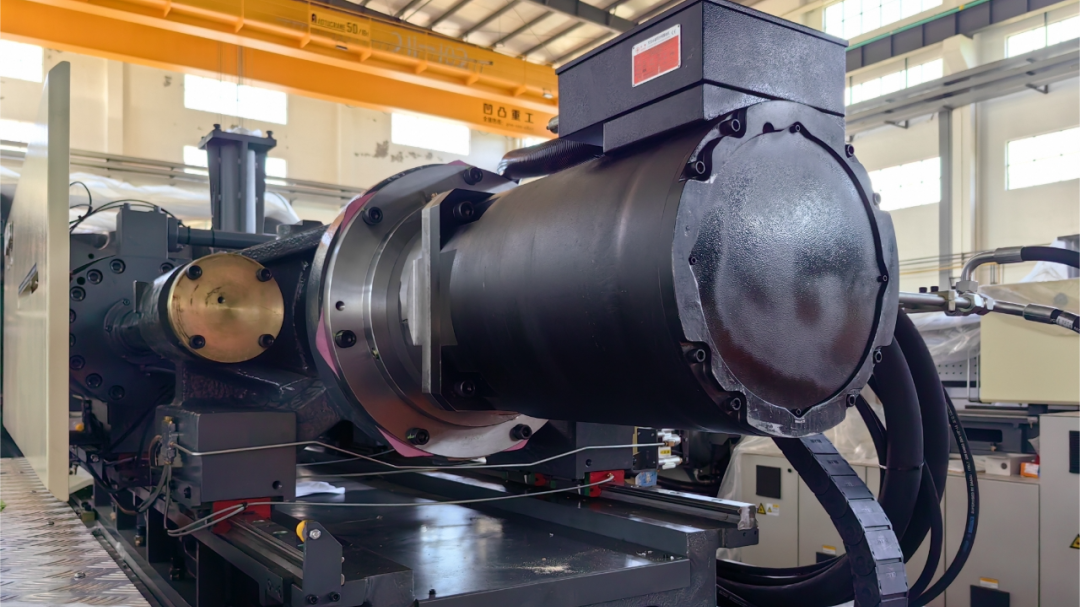

Yonghua Plastic Machinery Grandly Launches a New ModelYHIII Electric Pre-Plasticization Series Injection Molding Machine.This series deeply integrates core electro-preplasticization technology, achieving multidimensional breakthroughs in plasticizing performance, energy-saving effects, and overall machine stability, dedicated to providing you with more precise, reliable, and energy-efficient high-performance injection molding solutions!

Five Major Core Breakthroughs, Ushering in a New Era of Injection Molding Production

Speed increased by up to 40%

Breakthroughs in Plasticization Efficiency and Precision

YHIII Series

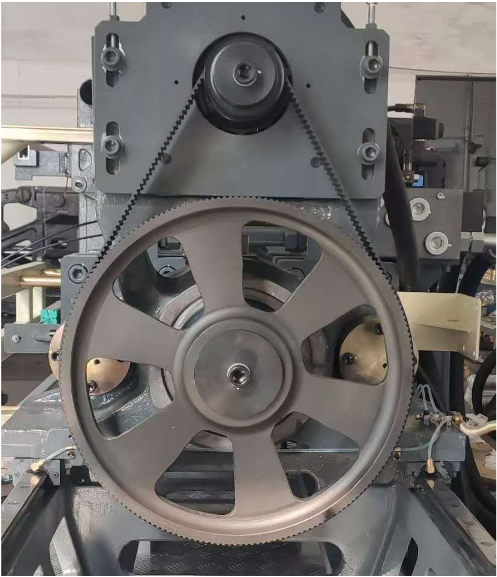

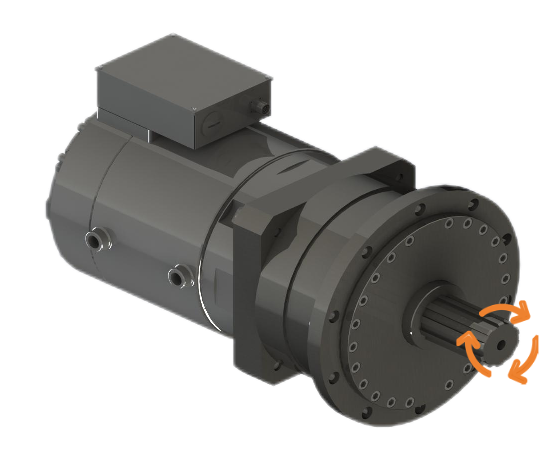

Using a servo motor in conjunction with synchronous belt drive or an integrated electric pre-plasticization system.Screw rotation speed significantly increased by 15%-40%The material storage accuracy is higher, the speed fluctuation is smaller, and the plasticizing speed and quality are significantly improved, making it especially suitable for high-end products with stringent molding process requirements.

Accuracy breakthrough of 0.3%

Injection control reaches new heights

Adopt a low-inertia injection design and a high-response control computer.Clamping force repeatability <0.5%,Injection accuracy <0.3%productMass repeatability <0.2%Ensure molding stability and consistency.

Energy savings of up to 35%

Significantly reduced energy consumption costs

Electric pre-plastic system paired with high-efficiency servo drive.Overall energy savings can reach up to 35%The synchronization of hot melt adhesive function further optimizes energy consumption, helping enterprises achieve green and low-carbon manufacturing.

The rigidity increases by 50%.

The service life is significantly extended.

By increasing the diameter of the tie bars, designing wide-area templates, and optimizing the clamping system, the rigidity, strength, and service life of the clamping components are significantly enhanced, easily adapting to large-size mold applications.

The maintenance cost has been significantly reduced.

Pollution-free and more environmentally friendly

The YH138Ⅲ-YH308Ⅲ models use synchronous belt drive and are built on all-electric technology. They feature mature technology, high reliability, low operating noise, and completely eliminate hydraulic oil leaks and cooling medium pollution, achieving true maintenance-free operation.

We deeply understand customers' concerns about production efficiency, product quality, and return on investment. The launch of the YHIII electric pre-plasticizing series is aimed at helping you increase productivity, reduce costs, and leverage advanced equipment advantages to face market competition.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track