Lou Jianfeng Leads Team for Inspection: Is BASF Interested in the COC "Little Giant"?

On September 12th, Dr. Jianfeng Lou, Chairman and President of BASF Greater China, and his delegation visited Topene Technology. The two parties conducted in-depth discussions on the innovative development and strategic cooperation of high-end polymer materials.

The two parties focused on discussing technological trends, market application scenarios, and potential areas of cooperation in the fields of optics and healthcare. In addition, Dr. Lou Jianfeng proposed several possibilities for collaboration during the exchange, including technology exchange and collaborative innovation on multiple levels.

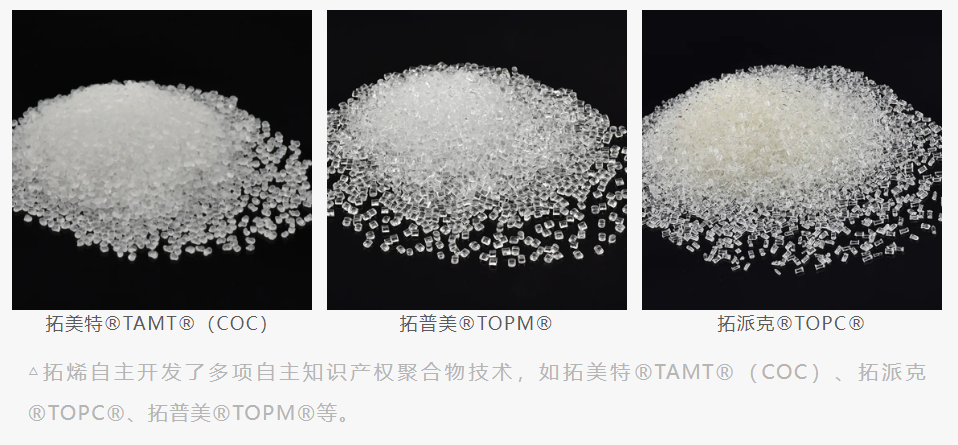

Tuoxi Technology, as a national-level "little giant" specializing in niche sectors, has overcome key technical challenges such as the synthesis of high-purity cyclic olefin monomers, the construction of metallocene catalyst systems, and the optimization of solution polymerization processes. The company has established production lines for optical medical-grade cyclic olefin copolymers (COC), optical-grade carbonate copolymers (TOPC), and optical-grade methyl methacrylate copolymers (TOPM), with a total production capacity of 51,000 tons. These products have achieved domestic substitution in fields such as optical lenses, biomedical applications, integrated circuits, aerospace, and intelligent driving. Tuoxi Technology has also established partnerships with leading companies such as Geely Automobile Research Institute, Yutong Optics, and Goertek Optics.

In June of this year, Tuoxin Technology successfully acquired land for the third phase base in Quzhou. The first phase of Tuoxin Technology, with a production of 3,000 tons of special cyclic olefin copolymer (SOOC® Tuomeite®), was successfully put into operation on November 30, 2023, and has now achieved full production and sales, successfully applied to products of over 20 leading companies. The second phase project, with an annual production of 7,000 tons of COC, has been successfully handed over, bringing the total COC production capacity to 10,000 tons per year, with supporting facilities for 6,000 tons of cyclic olefin copolymer monomer per year. With the upcoming delivery of the second phase project, Tuoxin will become the first domestic mass producer of high-end optical materials with an annual output of 41,000 tons. This project includes 1,000 tons of high-end optical TOPC and 40,000 tons of optical-grade TOPM.

Additionally, on June 20, 2024, the Smart Manufacturing City Branch of Quzhou Municipal Bureau of Ecology and Environment accepted the environmental impact assessment report for Tuoxin Technology's 7,000 tons/year SOOC project.

In the future, Tuoxin Technology plans to continue investing 10 billion yuan to accelerate its global expansion and steadily advance the planning of the third-phase COC project. This includes the phased construction of 60,000 tons per year of copolymerized cycloolefin monomer and 100,000 tons per year of COC materials. Simultaneously, they will plan for new materials products that address key technological bottlenecks in fields such as automotive materials and medical materials. In terms of market expansion, the focus will be on high-growth downstream sectors such as AR/VR and life sciences (including medical, aesthetic medicine, and in vitro diagnostics).

COC's market situation

Cyclic olefin copolymers (COC) are emerging high-performance polymer materials that are utilized in various fields due to their outstanding optical properties, low water absorption, high barrier properties, and good processing capabilities. They are applied in the optical field (such as mobile phone lenses, automotive lenses, AR/VR devices, etc.); in the medical field (such as prefilled syringes and pharmaceutical containers, etc.); and can also be used in other areas such as microtiter plates, biochips, and mobile device antennas.

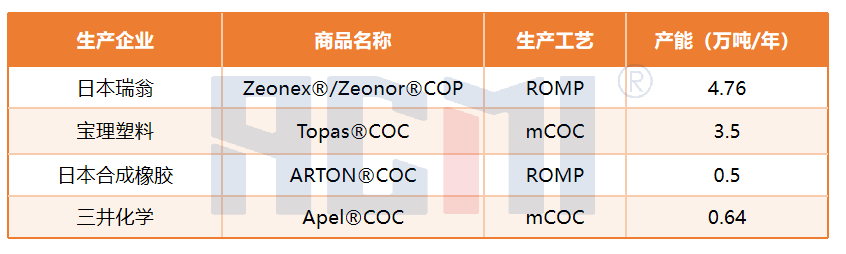

In the global COC market, Japanese companies dominate due to their extensive technical expertise and strong R&D capabilities. Major manufacturers include Zeon Corporation, Polyplastics, Mitsui Chemicals, and Japan Synthetic Rubber (JSR). By the end of 2024, the combined production capacity of COC/COP products is estimated to be around 90,000 to 100,000 tons.

In the domestic market, besides Tuoen Technology, several other companies such as Akoli, Liaoning Luhua Hongjin, Kingfa Sci & Tech, Wanhua Chemical, Yifeng Biochemical, and Gaifeng New Materials are also making arrangements. Among them, Akoli's "20,000-ton per year fatty amine expansion project and 10,000-ton per year new high-transparency material project (Phase II, 5,000 tons per year high-transparency materials)" is set to enter the production phase in June 2025 and has successfully produced qualified products. Liaoning Luhua Hongjin's COC facility was successfully commissioned at the end of January 2024 and smoothly passed the environmental protection acceptance in early September. This project has an annual production capacity of 500 tons of cycloolefin copolymer and 1,000 tons of norbornene (calculated as 100% norbornene). After completing the first phase demonstration project, there are plans for a second phase to construct a 10,000-ton per year cycloolefin polymer production facility.

It is worth mentioning that on the same day, BASF reached a strategic innovation cooperation agreement with the Quzhou Institute of Zhejiang University.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track