Lijin Plastics Machinery: Defining New Manufacturing Standards With Precision and Cleanliness

Currently, the injection molding machinery industry is facing the dual challenges of market saturation and shrinking profit margins.Mr. Xie Xiaosi, General Manager of Guangdong LK Injection Molding Machine Intelligent Manufacturing Co., Ltd., pointed out thatThe key to breaking the deadlock lies in achieving differentiated competition through technological innovation.He analyzed the medical industry as an example: "Low-end medical consumables have fallen into red ocean competition, while high-end medical equipment and related components demonstrate significant technological premium capabilities." Based on this assessment, LK has made all-electric injection molding machines a key R&D focus in the high-end medical sector, aiming to break the long-standing monopoly of foreign brands.

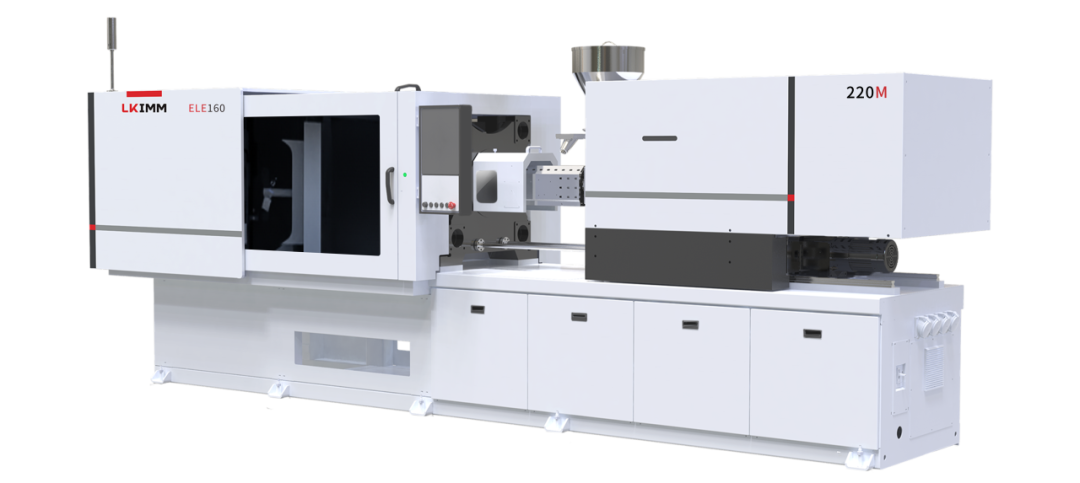

With the successful development of the ELETTRICA series all-electric injection molding machines, LK Group has made substantial breakthroughs in the field of medical production. This series adopts a high-rigidity clamping structure and a precision servo control system, achieving±0.01mm repeatability and millisecond-level response speedFully meets the stringent requirements of the production environment for medical products.

It is worth mentioning that Liking's all-electric injection molding machine demonstrates significant technological advantages. Compared with traditional hydraulic equipment, its innovative all-electric drive system achieves an energy utilization efficiency of up to95%Above all, the degree of mechanical wear is significantly reduced, and the overall energy-saving effect exceeds20%This breakthrough not only brings considerable economic benefits but also fundamentally addresses the pollution risks in medical device production with its oil-free design concept. Its clean production characteristics comply withISO 14644-1 Class 7 Cleanliness StandardIt can be widely applied in fields with stringent requirements for production environments. In the medical industry, this equipment meets the extremely high standards for cleanliness, precision, and stability required by implantable devices, advanced infusion instruments, as well as petri dishes, respirator masks, catheter hubs, and other products. It is also suitable for other high-end manufacturing sectors such as food packaging and infant products, providing various industries with precise, stable, flexible, efficient, and energy-saving solutions.

In terms of digital transformation, Lijin has developed an equipment lifecycle monitoring system based on the OPC-UA standard protocol. This system supports gigabit industrial Ethernet communication and is compatible with various industrial protocols such as Modbus-TCP. It enables real-time visualization of production data and remote diagnostics. According to Xie Xiaosi, the system has already achieved deep integration with ERP and MES systems of multiple customers, providing a complete production data traceability solution for injection molding products and offering a comprehensive digital foundation for the construction of smart factories. Additionally, Lijin has introduced AI algorithms into the production closed-loop control, endowing the production process with self-awareness, self-decision-making, and self-execution capabilities for complete closed-loop intelligent management and control, providing a benchmark solution for enterprise digital transformation.

Faced with increasingly fierce global market competition, from the domestic market to Southeast Asia, the Middle East, and other overseas markets, Lijin Plastic Machinery has chosen to break through with a deep customization strategy. "The logic of innovation has shifted from simple equipment parameter upgrades to mature solutions for specific segments," said Xie Xiaosi.From tariff policies and local industry characteristics to the operational habits of end customers, all have become important dimensions for the customization of our products.”

With the dual-drive strategy of "technological breakthroughs + precise focus," Lijin has achieved a critical leap from leading domestically to competing internationally. Xie Xiaosi emphasized: "We consistently benchmark against international top-tier technology, which is reflected not only in the continuous breakthroughs in product performance but also in our firm determination to create a world-class Chinese brand."Deepening technology is our most steadfast strategic choice, as it not only relates to achieving the goal of import substitution but is also fundamental to the sustainable development of the enterprise.”

In the process of reshaping the global manufacturing landscape, Lijin has demonstrated through practical actions that Chinese manufacturing companies are fully capable of competing with international giants in the high-end medical equipment field. Technological innovation, with precision and cleanliness at its core, is paving a new development path for the Chinese plastic machinery industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track