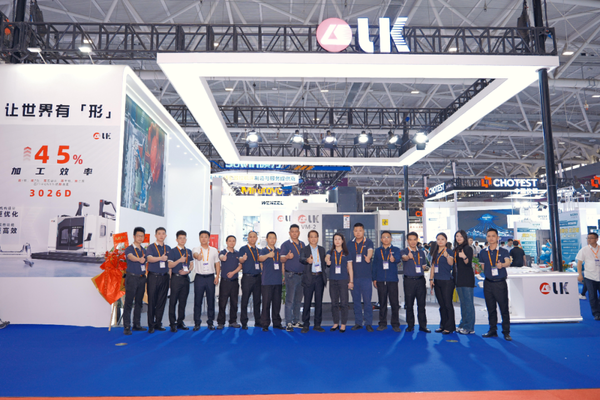

Lijin Group debuts at the 2025 ITES Shenzhen Industrial Exhibition, interpreting the future of digital precision machining transformation.

On March 26, the 2025 ITES Shenzhen Industrial Exhibition officially opened at the Shenzhen International Convention and Exhibition Center (Baoan) with the theme "Professionalism and Determination · Ultimate Innovation."

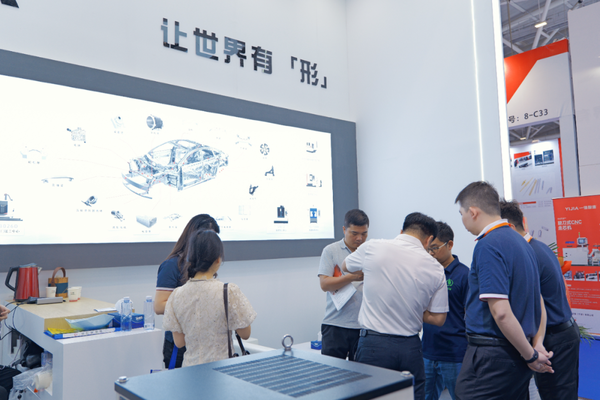

Lijin Group (Booth No.: 8C01) showcases its hard-core technological innovation achievements in precision processing, focusing on the manufacturing upgrade needs of new energy vehicles, motorcycles, yachts, and more, presenting a one-stop intelligent manufacturing solution from die-casting to machining.

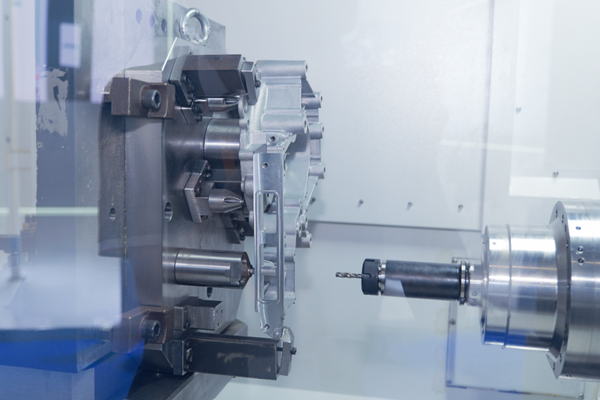

Lijin Group showcased advanced LHP-500 horizontal machining centers and VM-2 vertical machining centers, widely used in the processing of high-complexity and high-precision die-cast parts such as automotive engine middle shells, motorcycle gearbox housings, yacht cylinder bodies, timing chain cover lids, valve bodies, and transmission casings, empowering customers to achieve a dual leap in processing efficiency and quality.

The LHP-500 horizontal machining center adopts high-precision four-axis linkage processing, with a super-strong structural body, high-rigidity integrated base, and internal spindle laying the foundation for high-precision machining. It features a rapid displacement of 60m/min, high acceleration of 0.6G, automatic tool changing, and automatic worktable exchange, redefining the boundaries of intelligent manufacturing.

The VM-2 vertical machining center uses a high-torque spindle motor, demonstrating excellent cutting performance in the processing of mass-produced parts such as aluminum and cast iron. The Fanuc 0i-MF Plus system, 12000rpm direct connection spindle, and 24-tool arm-type tool magazine provide high stability and processing yield, assisting customers in building a flexible intelligent manufacturing system.

"Integrated Die Casting + Intelligent Machining" Technology Matrix Empowers Enterprises' Digital Transformation

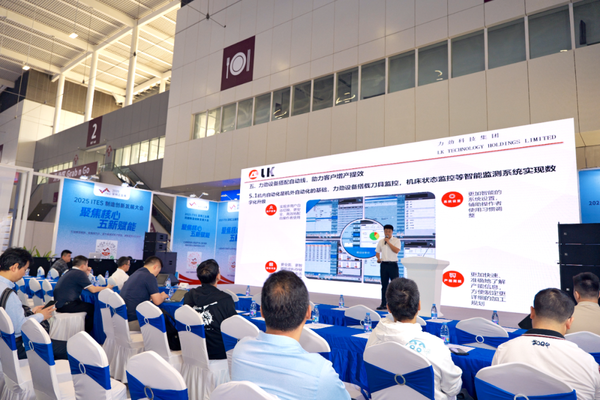

At the same time, at the New Energy Vehicle Intelligent Manufacturing Development Forum, Mr. Xu Xinjian from Lijiang Group's Technology Center was invited to give a speech titled "Lijiang's Support for the Optimization and Upgrade of Post-Casting Processing Solutions for New Energy Vehicles."

Mr. Xu Xinjian stated that the new energy vehicle industry is undergoing three major transformations: "the continuous release of policy dividends," "the disruptive impact of integrated die-casting processes on traditional manufacturing models," and "the accelerated penetration of intelligent manufacturing technologies." Lijiang Group continues to drive China's manufacturing towards greater efficiency and intelligence with a dual approach of "technology + ecosystem."

The new process of "integrated die-casting + machining" is gradually replacing the traditional process of "sheet metal stamping + welding." The Lijin GF5/GP5 series gantry-type five-axis machining centers, GU series gantry-type double-beam double five-axis machining centers, MCG5 series five-axis moving-column gantry machining centers, LHP series horizontal machining centers, and LHU series horizontal five-axis milling-turning composite machining centers are continuously optimizing and upgrading the processing technology for integrated die-cast parts and related components in the new energy vehicle industry.

"Power Force Group is dedicated to the innovative research and development of integrated die-casting parts for new energy vehicles and machining processes for 'three electrics' system structural components. The intelligent manufacturing excellent scenario applications are supported by an intelligent layer within the machine, a production line collaboration layer, and a cloud management platform, constructed using a tool monitoring system, a machine status monitoring system, an RFID intelligent monitoring system, and a loader/robot conveyor system. This helps customers achieve digital upgrades and improve production efficiency," Mr. Xu Xinjian stated.

As China's high-end equipment manufacturing industry advances towards high precision, intelligence, and sustainability, the machining sector is showing trends of digitalization, intelligence, efficiency, and diversification. Lijiang Group continues to promote the research and development of innovative technologies and their industrial application, helping enterprises strengthen their supply chains, reduce costs, increase efficiency, and maintain competitiveness.

The 2025 ITES Shenzhen Industrial Exhibition will continue until March 29. Please continue to visit the Likang booth for discussions and to explore innovations in precision manufacturing technology and paths for industrial upgrading. Likang booth number 8C01!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track