Lightweighting Becomes a Trend: Bole Intelligence Helps Humanoid Robots Usher in a "Magnesium" Era

Humanoid robots are rapidly evolving, with lightweight design becoming an inevitable trend. Their early development began in the 1960s, and with technological advancements, robots have acquired the ability to independently perform complex actions. A humanoid robot consists of four main modules: perception, decision-making, control, and execution. Among these, the execution module functions like human muscles, responsible for limb movement. To achieve highly flexible human-like motions, lightweight design can significantly reduce the load on the drive system, enhance load-bearing capacity, lower power consumption, and extend lifespan. This is crucial for performance improvement and commercial implementation. Magnesium alloys, with their unique performance advantages, are quietly emerging in the field of humanoid robots.

Lightweight and high-strength

Magnesium alloys are lighter and stronger than aluminum alloys, which can reduce the weight of humanoid robots and enhance their mobility and speed, offering more possibilities for the application of humanoid robots.

● Heat dissipation

Magnesium alloy has excellent thermal conductivity, with a thermal conductivity coefficient surpassing most engineering plastics and some aluminum alloys. It is 350 to 400 times that of ABS resin, enabling rapid conduction of heat from joint actuators to prevent overheating, as well as quickly dissipating heat from internal electronic components of robots, ensuring stable operation and avoiding malfunctions.

●Diversity of styles

Magnesium alloys can undergo various surface treatments such as oxidation, painting, and electrophoresis, making humanoid robots more attractive and durable, and meeting the needs of personalized customization.

●Durability

Magnesium alloys, owing to their metallic nature, are resistant to UV radiation and damp heat aging, with no risk of plastic embrittlement and superior creep resistance. Through surface technologies such as micro-arc oxidation, their corrosion drawbacks can be systematically addressed, achieving a balance between lightweight and long-term stability, making them an ideal material choice for humanoid robot joints and skeletons.

►Robotic Arm

The robotic arm is one of the important components of a humanoid robot, requiring strong load-bearing capacity and flexible motion functions. By utilizing the lightweight and high-strength advantages of magnesium alloy, robotic arms with greater load-bearing capacity and more agile movements can be manufactured.

►Skeleton Structure

The skeleton structure of a humanoid robot needs to have good durability and stability, capable of maintaining the structural integrity of the material under high-speed motion and heavy loads. Magnesium alloy possesses excellent durability and stability, which can meet the requirements of the humanoid robot's skeleton structure.

Joint transmission mechanism

The joint transmission mechanism is one of the key components of humanoid robots, requiring efficient transmission capability and reliable operational stability. Using magnesium alloy materials can meet the requirements for efficient transmission and reliable stability, enhancing the overall performance of humanoid robots.

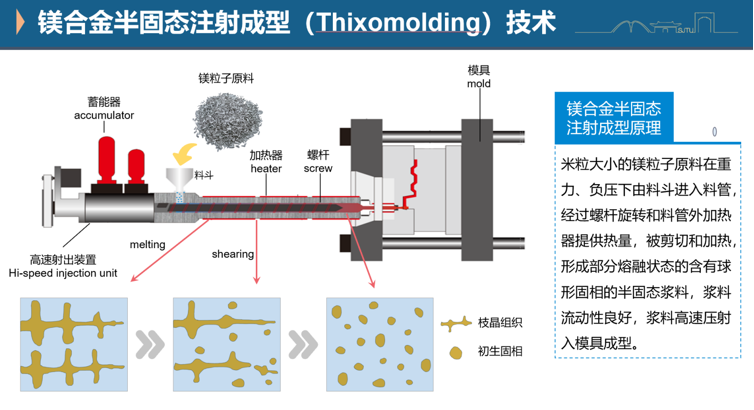

- Completely eliminate furnaces and SF6 gas for safer and greener processes.

Materials are injection molded in a semi-solid state, resulting in lower energy consumption and higher efficiency.

MTX2000D Two-Plate Magnesium Alloy Semi-Solid Injection Molding Machine

Bole Intelligence has been deeply engaged in the magnesium alloy forming field for many years, independently developing semi-solid magnesium alloy injection molding machines. It has successively launched 300-4000T magnesium alloy forming equipment and introduced it to the market. Bole adopts semi-solid thixotropic forming technology, utilizing semi-molten magnesium alloy for injection molding, which significantly reduces issues such as part shrinkage, gas entrapment, corrosion, and reliability problems during the forming process. This results in higher material utilization while reducing energy consumption.

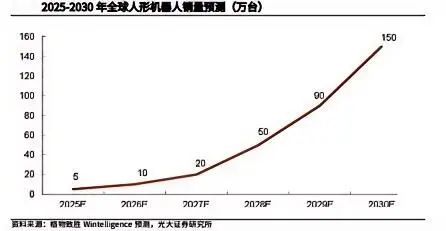

With the significant improvement in magnesium supply and the maturation of semi-solid injection molding technology for magnesium alloys, magnesium alloys are expected to be used in components such as the skeleton, shell, joints, and heat dissipation and shock absorption parts of robots.

The application of magnesium alloys is not just a matter of technological substitution; it is also key to the transition of humanoid robots from "functional implementation" to "performance leap." Strong policy support, innovative practices by enterprises, and continuous technological breakthroughs are jointly driving magnesium alloys from the laboratory to a hundred-billion-level market. In the future, as AI large models deeply integrate with materials science, "intelligent magnesium alloys" may enable humanoid robots to surpass current limitations.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track