KRICT Develops New Transfer Method to Create Safer, Longer-Lasting Lithium Metal Batteries

According to foreign media reports, a research team from the National Research Council of Science and Technology of Korea has developed a breakthrough transfer technology that can form a thin protective layer on the surface of lithium metal. This innovation is expected to solve the long-standing dendrite problem that has plagued next-generation lithium metal batteries.

Image Source: KRICT

Dr. Jungdon Suk's team at the Advanced Battery Research Center of the Korea Research Institute of Chemical Technology (KRICT) successfully transferred a hybrid protective layer composed of solid polymer and ceramic onto lithium metal using a solvent-free process. The related research paper was published in the journal Energy Storage Materials.

Unlike traditional wet coating methods, this technology can achieve uniform coating over large areas without damaging the surface of active lithium, marking a significant step toward commercial viability.

Lithium metal batteries are the next generation of energy storage systems, using lithium metal instead of graphite as the anode. The theoretical capacity of lithium metal anodes is ten times that of conventional lithium-ion batteries and is a key material for high-energy-density solid-state batteries and lithium-sulfur batteries.

However, the risk of dendrite formation during charge-discharge cycles poses safety hazards, including the risks of short circuits and fires, and also limits battery lifespan. In addition, traditional wet coating processes rely on organic solvents, which can introduce impurities and cause surface damage, making large-scale production and commercialization more complex.

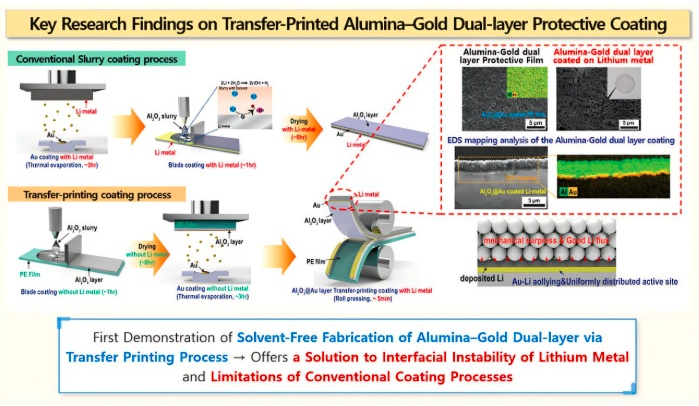

To overcome these challenges, the research team developed two types of protective layers: a bilayer consisting of aluminum oxide (Al₂O₃) and gold (Au), and a hybrid layer composed of ceramic (Al-LLZO) and polymer components. Subsequently, the researchers used roll-to-roll transfer technology to laminate these protective layers onto lithium metal, marking the first demonstration of this method in the field.

The technology forms a protective layer on a separate substrate and then transfers it onto lithium using pressure, without the use of solvents, minimizing lithium damage while improving uniformity and process repeatability.

In early studies, the Al2O3-Au bilayer structure effectively suppressed dendrite growth and maintained stable cycling performance by leveraging mechanical strength and reduced interfacial resistance. This research was the first to introduce transfer printing technology to address interfacial instability and the limitations of wet coating methods.

On this basis, the research team has now demonstrated a method for transferring an ion-conductive flexible hybrid protective layer over an area of 245 × 50 mm, with the protective layer having a thickness of only 5 micrometers.

These mixed layers inhibit dendrite growth and induce uniform lithium-ion flux at the electrode-electrolyte interface, thereby achieving stable cycling performance. The uniform transfer of large-area protective films not only confirms the advanced nature of the technology but also demonstrates its scalability for commercialization.

In the soft-pack battery test, the mixed protection lithium anode retained 81.5% of its capacity after 100 charge-discharge cycles, with an overpotential as low as 55.34 mV and a coulombic efficiency of up to 99.1%, making its stability more than twice that of bare lithium batteries. Even under high-rate conditions with complete discharge in 9 minutes, the battery was able to maintain 74.1% of its initial capacity, demonstrating fast, stable, and efficient cycling characteristics.

The team expects that this innovation will accelerate the practical application of lithium metal batteries in high-energy applications such as electric vehicles and energy storage systems (ESS). Additionally, the technology is anticipated to extend to solid-state batteries and lithium-sulfur batteries, further advancing next-generation battery platforms.

Dr. Suk stated, "This study combines novel protective materials with a scalable transfer process, overcoming key challenges such as interfacial instability in lithium metal batteries and the limitations of wet processing."

Dr. Young-Kuk Lee, Director of KRICT, added, "This is one of the most practical solutions to achieve high energy density lithium metal batteries, which is expected to enhance Korea's competitiveness in the global battery industry."

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track