K Show Moment | Innovative Injection Molding Meets Digital Technology as KraussMaffei Leads in Energy Efficiency

As K 2025 approaches, KraussMaffei will focus on showcasing its latest achievements in injection molding, automation, and additive manufacturing that empower the polymer processing value chain. Highlights of the exhibition will include improvements in production efficiency, optimization of component quality, realization of sustainable development, and advancement of digital transformation.Intuitive MC7 control system of the all-electric PX series injection molding machine, innovative short-cut fiber processing (CFP) technology, automated assembly production line, and digital innovation solutions for additive manufacturing.

KraussMaffei's core competitiveness stems from the integration of innovative mechanical engineering, deep process knowledge, and intelligent digital solutions. This advantage spans the entire spectrum of injection molding, automation, reaction molding, extrusion, and additive manufacturing. Leveraging a global service network and digital tools, we provide customers with cost-effective lifecycle support.

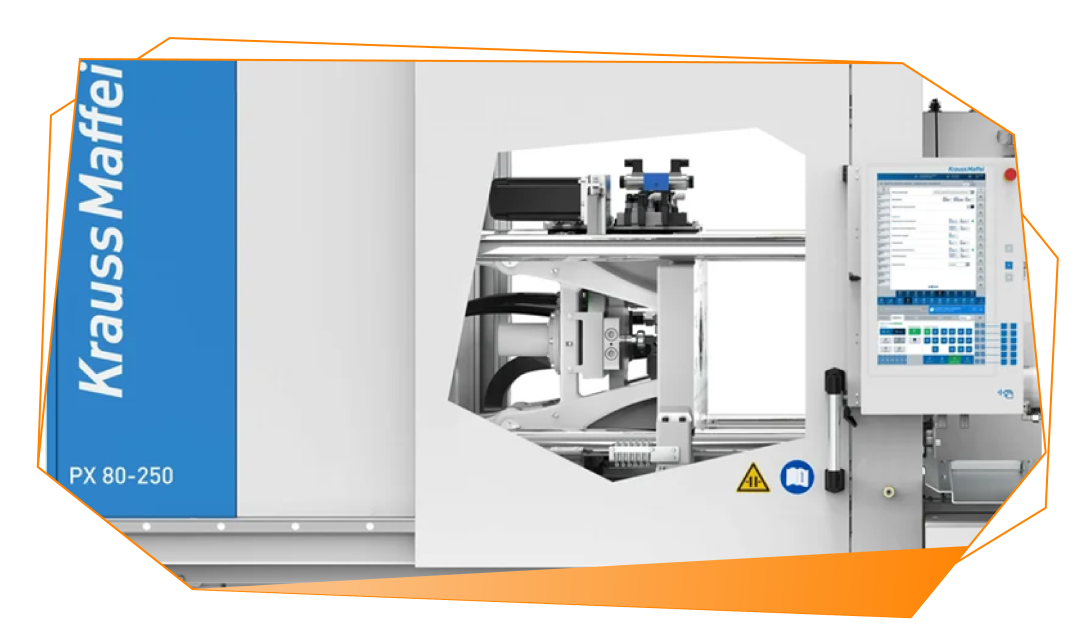

At K 2025, KraussMaffei willGlobal launch of the all-new PX injection molding machine series.Combining compact design, exceptional performance, and sustainable production, it sets a new industry benchmark with outstanding energy efficiency, stable injection precision, and shorter cycle times. Based on superior cost-effectiveness and ultra-long service life, this series further integrates resource optimization designs such as energy recovery drive and low media consumption, allowing the equipment to achieve maximum energy efficiency both in operation and standby, providing customers with sustainable solutions with long-term value.

At the exhibition site, the PX injection molding machine and the new LRXplus linear robotic arm will demonstrate efficient collaboration, showcasing their highly flexible integration capabilities.LRXplus offers broad compatibility, capable of adapting to different brands of injection molding systems and a variety of automation tasks.The audience can closely observe the practical applications of the unit in fields such as healthcare, industrial components, and packaging.

Simultaneous deviceThe KraussMaffei MC7 new generation control system is a modern control platform based on a network.With a focus on a robust hardware and software architecture and forward-thinking network security design as core highlights, it significantly simplifies device setup, daily operations, and maintenance processes through clear user guidance and extended functionalities, comprehensively enhancing production efficiency and user experience.

The innovative Chopped Fiber Processing (CFP) technology provides a cost-effective solution for the direct compounding of polypropylene with glass fibers. Compared to traditional long glass fiber pellets, CFP offers greater production flexibility and significant cost advantages while maintaining the same performance of the components.

The process employs a patented screw geometric structure, ensuring efficient melting and uniform mixing of materials, achieving high-quality fiber-reinforced components while maximizing material utilization.The CFP process is compatible with all KraussMaffei standard injection molding equipment and can be easily retrofitted through professional services to achieve a quick return on investment.

At the exhibition site, the complete CFP processing of complex automotive tailgate components will be demonstrated using the GX 650-4300 injection molding machine, showcasing its stable performance and outstanding capabilities.

KraussMaffei will also showcase a modular autonomous assembly unit at K Fair, further expanding its automation landscape. This compact mobile unit can perform high-precision assembly of three plastic components in real-time without human intervention, with a very short cycle time and minimal error rate.

The assembly process uses bonding shear technology, with a laser scanner detecting component dimensions with an accuracy of 0.01 millimeters.The optical inspection system automatically identifies and sorts out defective products, while the good products are directly packed.

Digitalization is at the core of KraussMaffei's strategy to enhance production efficiency. At this exhibition, a series of innovative achievements will be showcased: the socialProduction intelligent production advisor has added a data set management feature, enabling seamless machine data migration and version comparison; the real-time AI assistance system provides decision support for operators; the APCplus function has also been upgraded, featuring the new cascadeX intelligent needle valve control and the materialX customer-specific material database, achieving comprehensive intelligent optimization from production to processes.

After successfully launching the powerPrint industrial-grade large-format 3D printing system at K 2022, KraussMaffei is further expanding its additive manufacturing product line at K 2025.Launch the new models powerPrint FLEX and printCore.The modular system is designed for industrial-grade applications, offering outstanding flexibility, high production efficiency, and consistently excellent print quality in fields such as design, mold manufacturing, and functional end components.

At the exhibition site, KraussMaffei will dynamically demonstrate the actual operation of the powerPrint FLEX in conjunction with the printCore extruder through an industrial robot unit, showcasing its diverse application capabilities in mold making, functional part forming, and design model construction.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track