K Exhibition Day One | Refresh Your Injection Molding Experience! Huada Machinery Unveils All-Electric Intelligent Injection Molding Solutions at Germany's K Exhibition

The top event in the global plastics and rubber industry - the 23rd International Plastics and Rubber Exhibition (K Fair) will be grandly held at the Düsseldorf Exhibition Centre in Germany from October 8 to 15, 2025.

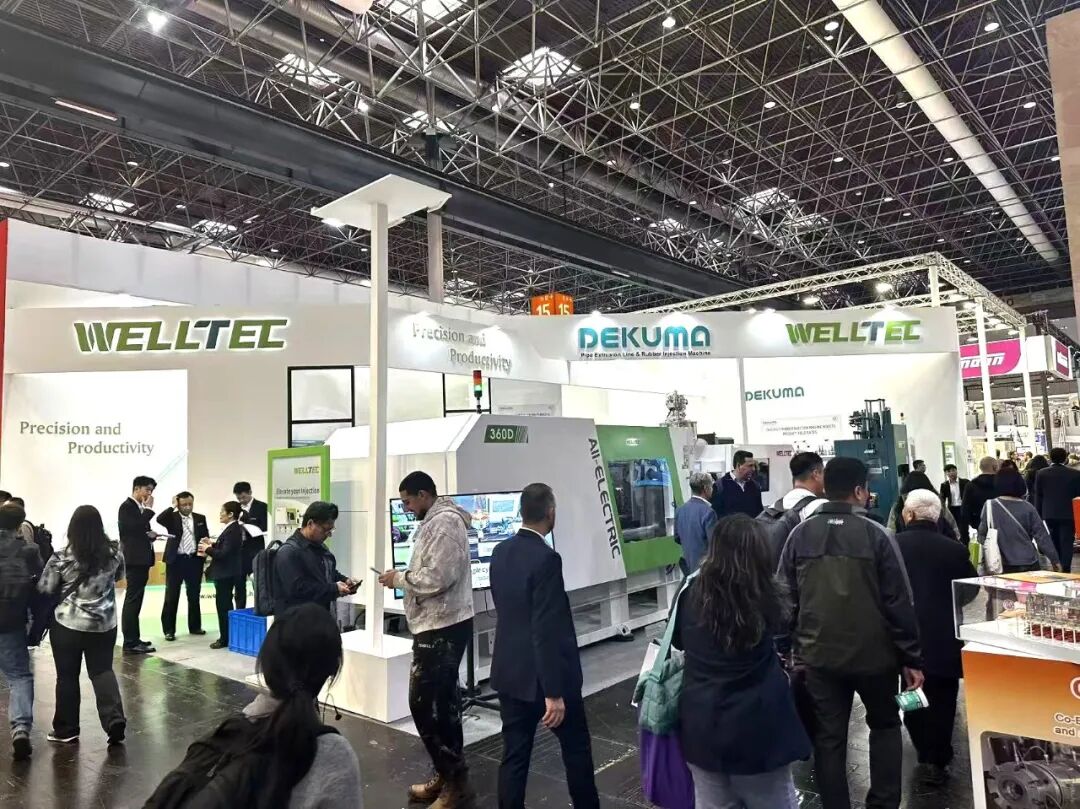

As an innovative force in the injection molding industry, Huada Machinery once again shines at K Fair with the theme "Elevate Your Injection Experience."Hall 15, A37The booth showcases its latest achievements in the field of efficient, precise, and environmentally friendly injection molding.

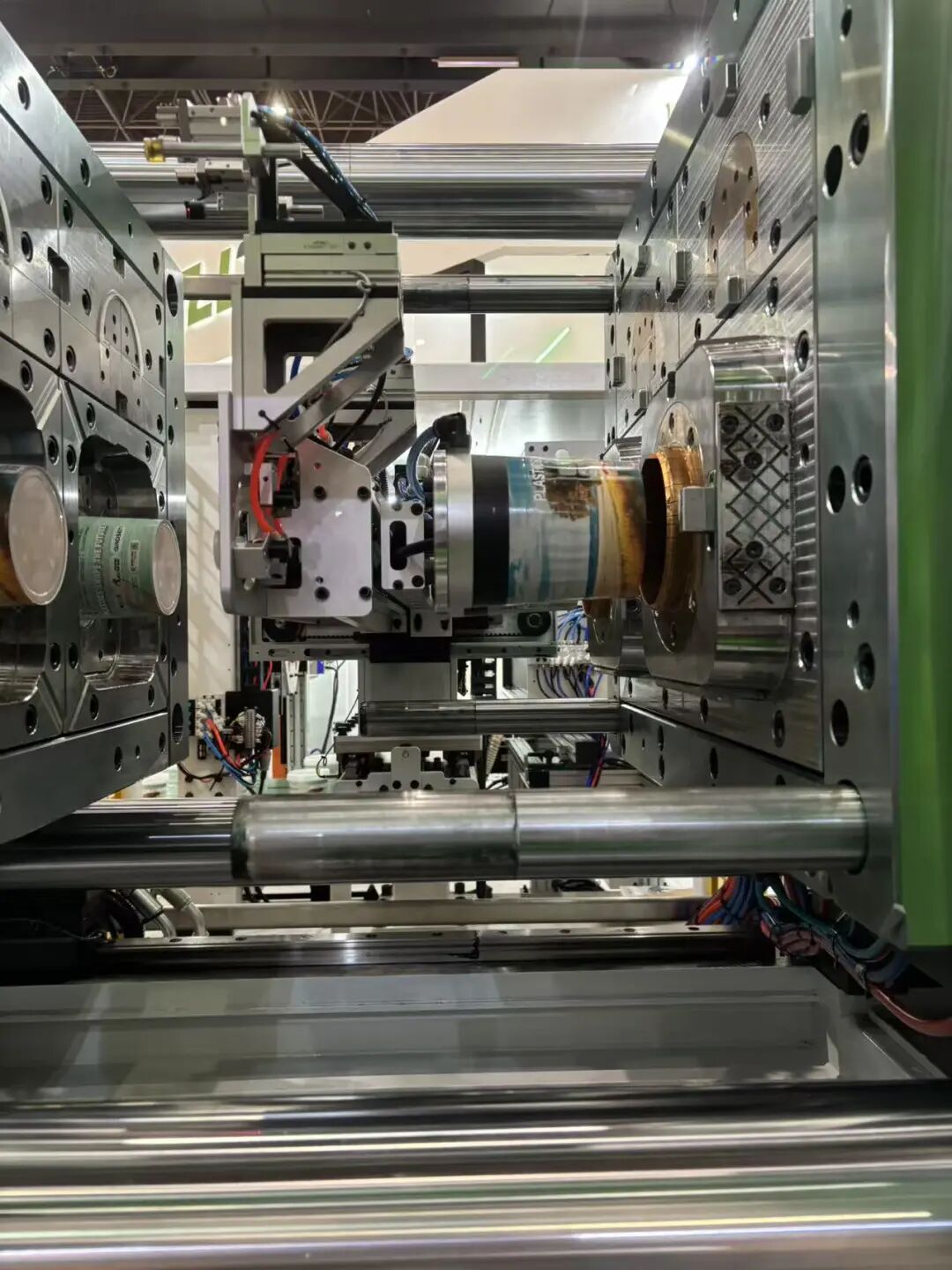

Fully Electric Injection Molding Solution Production Line

WELLTEC

At this exhibition, Huada Machinery is showcasing its advanced 360D all-electric one-stop injection molding solution, with a live demonstration of the in-mold labeling fully automated production process for 1L food buckets (including handles). This integrated solution offers customers a high-efficiency, high-quality smart manufacturing experience.

All-electric injection molding machines stand out in the industry due to their excellent performance advantages. They feature high precision, high repeatability, low noise, and energy-saving and environmentally friendly characteristics. By using servo motors to directly drive each actuator, they effectively improve energy utilization efficiency, achieving a 30%-50% energy-saving effect compared to traditional hydraulic machines.

In addition, the all-electric design eliminates the risk of hydraulic oil leakage, ensuring a clean production environment, which is particularly suitable for food packaging and medical device production with extremely high hygiene requirements. Its rapid response and high sensitivity actions can significantly shorten the production cycle and improve production efficiency.

▼

Deeply Integrated Automated In-Mold Labeling Solution

1

At the exhibition site, we showcased precision molds in collaboration with our strategic partner, Branson, which ensure high-precision forming of products and accurate positioning of labels. The exquisite design of the molds guarantees the surface quality of the products and the perfection of label integration.

2

The accompanying Janssen industrial high-speed robotic arm is capable of placing pre-printed labels with ultra-high precision and speed into the mold cavity and quickly removing the labeled 1L food containers after the injection molding cycle is completed. This significantly enhances production efficiency, reduces manual intervention, ensures stable operation of the production line, and brings tangible benefits to the customer.

While establishing an advantage in fields such as food packaging and medical devices with all-electric injection molding machines, Huada Machinery has also built a more comprehensive product matrix. We simultaneously offer high-performance hydraulic injection molding machines, such as the PET series special machines, SeKIII series standard machines, Se5 servo series injection molding machines, and two-platen injection molding machines. Additionally, we launch targeted customized injection molding solutions that cover a broader range of industrial scenarios, including automotive parts, smart home, and packaging containers, to meet the production needs of different markets through diverse technological paths. This comprehensive product layout also lays the core foundation for us to serve global customers and deepen international market cooperation.

Build a new pattern of global intelligent manufacturing.

WELLTEC

The global plastics industry is undergoing profound changes, demanding higher production efficiency, resource utilization, and sustainable development. Huada Machinery keenly observes these global trends and actively participates in them. We are committed to integrating intelligent, automated, and sustainable development concepts into every piece of equipment and solution. The all-electric injection molding machine one-stop solution showcased this time is the result of our deep cultivation in these three core areas—it provides global customers with a clean and efficient production model through its excellent energy efficiency, high precision, and stability.

Currently, BGI Machinery has established a wide sales network and customer base in major global markets and regions, including Asia, Europe, North America, South America, and Africa. We provide not only leading injection molding equipment but also comprehensive solutions that help customers enhance their competitiveness and achieve sustainable development. During the K Fair, we look forward to in-depth exchanges with global partners and customers to explore innovative opportunities in the plastics and rubber industry together, and to jointly create a green, intelligent, and sustainable industrial future!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track