Jinwei Machinery | Leading a New Height in PVC-O Pipe Production

In the field of plastic pipes, PVC-O pipes are gradually becoming a popular choice in the industry due to their outstanding performance and wide application prospects. As a leading enterprise in China's plastic machinery industry, Jinwei Machinery has successfully launched an advanced PVC-O pipe production line, injecting new vitality into the development of the industry with its profound technical accumulation and innovative spirit.

In the field of plastic pipes, PVC-O pipes are gradually becoming a popular choice in the industry due to their outstanding performance and broad application prospects. As a leading enterprise in China's plastic machinery industry, Jwell Machinery has successfully launched an advanced PVC-O pipe production line, thanks to its profound technical accumulation and innovative spirit, thus injecting new vitality into the development of the industry.

What is PVC-O pipe?

What is PVC-O pipe?

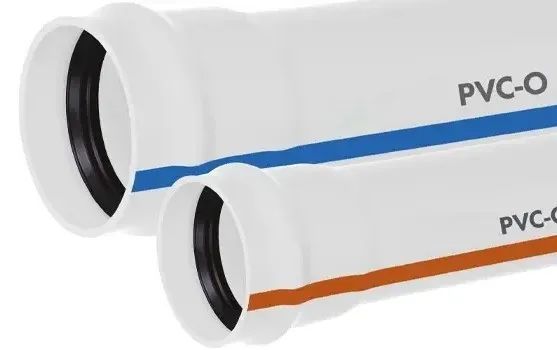

PVC-O, or biaxially oriented polyvinyl chloride pipes, are produced through a special biaxial stretching process that stretches PVC-U pipes both axially and radially. This process aligns the long-chain molecules of PVC in a biaxial manner, forming a network structure. This unique manufacturing process endows PVC-O pipes with excellent properties such as high strength, high toughness, high impact resistance, and fatigue resistance.

PVC-O, also known as biaxially oriented polyvinyl chloride pipe, is produced through a special biaxial stretching process. In this process, PVC-U pipes are stretched both axially and radially. This causes the long-chain PVC molecules in the pipe to be aligned in a regular manner in both axial and radial directions, forming a mesh-like structure. This unique manufacturing process endows PVC-O pipes with excellent properties such as high strength, high toughness, high impact resistance, and fatigue resistance.

Advantages of PVC-O pipes

The Advantages of PVC-O Pipes

High strength and high toughness

High Strength and High Toughness

The impact strength of PVC-O pipes is more than 10 times that of ordinary PVC-U pipes, and it maintains good impact resistance even in low-temperature environments. Its ring stiffness and tensile strength are significantly improved, allowing it to withstand greater pressure and load.

The impact strength of PVC-O pipes is more than 10 times that of ordinary PVC-U pipes. Even in low-temperature environments, they can maintain excellent impact resistance. Their ring stiffness and tensile strength are significantly improved, allowing them to withstand greater pressures and loads.

Material conservation and environmental protection

Material Conservation and Environmental Protection

Due to the optimized molecular structure of PVC-O pipes, their wall thickness can be reduced by 35%-40% compared to PVC-U pipes, significantly saving raw materials. At the same time, the production process of PVC-O pipes is more energy-efficient and has lower carbon emissions, aligning with the requirements of sustainable development.

Thanks to the optimized molecular structure of PVC-O pipes, their wall thickness can be reduced by 35% to 40% compared to PVC-U pipes, which greatly conserves raw materials. In addition, the production process of PVC-O pipes is more energy-efficient and generates lower carbon emissions, meeting the requirements of sustainable development.

Long lifespan and corrosion resistance

Long Service Life and Corrosion Resistance

The service life of PVC-O pipes can reach 50 years, which is twice that of ordinary PVC-U pipes. It also has excellent resistance to chemical corrosion, making it suitable for various complex environments.

The service life of PVC-O pipes can reach up to 50 years, which is twice that of ordinary PVC-U pipes. They also possess excellent resistance to chemical corrosion, making them suitable for a variety of complex environments.

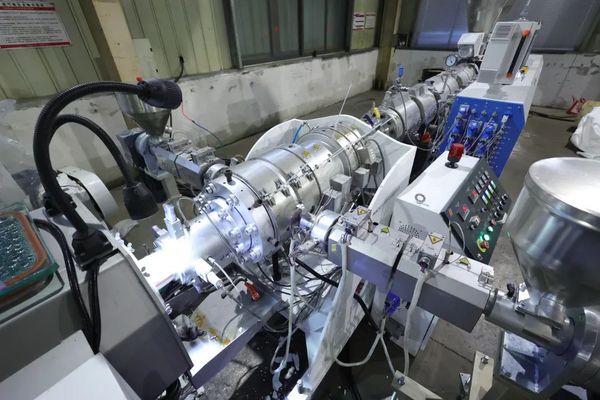

Jinwei Machinery's PVC-O pipe production line

Jwell Machinery's PVC-O Pipe Production Line

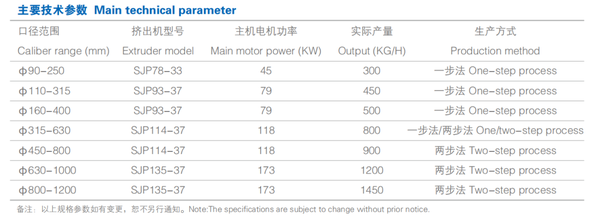

Jinwei Machinery's PVC-O pipe production line utilizes advanced biaxial stretching technology, ensuring high quality and performance of the pipes. The design of the production line fully considers production efficiency and stability, capable of meeting diverse customer needs. It features high energy efficiency, high-quality molding, a high degree of automation, a small footprint, environmental sustainability, multi-zone heating technology, and customization and flexibility. In addition, Jinwei Machinery offers one-stop services from equipment selection to installation and debugging, as well as after-sales maintenance.

Jwell Machinery's PVC-O pipe production line employs advanced biaxial stretching technology, ensuring the high quality and superior performance of the pipes. The design of the production line fully takes into account production efficiency and stability, and is capable of meeting the diverse needs of customers. It features high efficiency and energy conservation, high-quality forming, a high degree of automation, small floor space, environmental friendliness and sustainability, multi-stage heating technology, as well as customization and flexibility. In addition, Jwell Machinery also provides one-stop services ranging from equipment selection to installation, commissioning, and after-sales maintenance.

PVC-O production line

Application Fields

PVC-O pipes are widely used in municipal water supply and drainage, agricultural irrigation, mining pipelines, non-excavation installation, and repair fields. Their excellent performance and cost-effectiveness make them stand out in market competition.

PVC-O pipes are widely used in fields such as municipal water supply and drainage, agricultural irrigation, mining pipelines, and trenchless installation and rehabilitation. Their excellent performance and cost-effectiveness have enabled them to stand out in market competition.

Jinwei Machinery is committed to providing customers with high-quality plastic extrusion equipment and solutions. In the field of PVC-O pipes, we will continue to leverage our technological advantages to promote industry development. Choosing Jinwei Machinery means choosing an efficient, energy-saving, and environmentally friendly future.

Jwell Machinery is always committed to providing customers with high-quality plastic extrusion equipment and solutions. In the field of PVC-O pipes, we will continue to leverage our technological advantages to drive industry development. Choosing Jwell Machinery means choosing a future that is efficient, energy-saving, and environmentally friendly.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track