Jilin Petrochemical's 400,000 Tons Per Year HDPE Unit Starts Up! A Review of 30 New Production Capacity Projects

Recently, the key units of the Jilin Petrochemical transformation and upgrading projectThe 400,000 tons/year high-density polyethylene (HDPE) unit has officially begun feeding and startup, successfully producing qualified products in a single attempt. This marks the full integration of the process flow for the unit and the achievement of a major milestone in the project’s construction.

In 2025, China will see the commissioning of eight new polyethylene production enterprises, with a total added production capacity of 6.58 million tons. Aside from the breakthrough progress of Jilin’s 400,000 tons/year high-density polyethylene (HDPE) unit, what are the developments of the other projects? Below, Special Plastic Vision will give you a comprehensive overview.

HDPE Project Progress Overview

Jilin Petrochemical's 400,000 tons/year HDPE unit has officially started feeding and commissioning.

At 8:00 on July 28, the first reactor of the 400,000 tons/year high-density polyethylene unit in the ethylene plant transformation and upgrade project was charged with catalyst. At 10:28, ethylene was introduced into the first reactor to start up the unit. At 18:40 on the 29th, the entire process was successfully connected, and the extrusion pelletizing unit produced polyethylene pellets, achieving a successful first startup. This marks the official commencement of production and operation of the unit.

It is reported thatThe 400,000 tons/year high-density polyethylene plant adopts advanced low-pressure slurry process technology introduced from LyondellBasell in Germany. It can produce 29 types of high-performance grades including injection molding, blow molding, and pipe materials, characterized by high strength, high rigidity, and excellent weather resistance. These products are widely used in high-end pipes, films, cable sheaths, and other fields.

The 200,000-ton/year HDPE project of Huajin Aramco Petrochemical has achieved mechanical completion.

On July 29, the 200,000-ton-per-year high-density polyethylene (HDPE) unit and the 300,000-ton-per-year propylene oxide (HPPO) unit of Huajin Amec Petrochemical, EPC contracted by Shanghai Engineering Company, achieved mechanical completion, marking a significant milestone in the construction of the Northern Huajin Fine Chemicals and Raw Materials Engineering Project.

Guangxi Petrochemical Refining and ChemicalA 300,000 tons/year HDPE unit held a mechanical completion ceremony.

On July 10th, the 300,000-ton/year High-Density Polyethylene (HDPE) unit of the Guangxi Petrochemical Refining and Chemical Integration Transformation and Upgrade Project held a handover ceremony, marking the transition of the unit from the construction phase to the commissioning preparation phase. As a key project for the transformation and upgrade of Guangxi Petrochemical's refining and chemical integration, the 300,000-ton/year HDPE unit was constructed under an EPC consortium contract by Global Jilin Company and the company. The high-end polyethylene products produced by this unit can be widely used in fields such as food packaging, medical devices, and automotive components.

4. Shandong New Era Polymer Materials Co., Ltd.450,000 tons/year HDPE

In February 2025, Shandong New Era Polymer Materials Co., Ltd.'s 450,000-ton/year HDPE unit successfully produced qualified products.Shandong New Era Polymer Materials Co., Ltd. was established in In January 2021, located in the Maqiao Chemical Industry Park, the existing projects include a 300,000 tons/year hydrogen peroxide-based propylene oxide unit and a supporting 900,000 tons/year hydrogen peroxide unit. Projects under construction include a 700,000 tons/year high-end polyolefin project, among others.

5. BASF Integrated SiteGuangdong Co., Ltd. 500,000 tons/year HDPE

BASF Zhanjiang Project was established in In July 2018, it was officially announced as an integrated chemical production site and is BASF’s largest investment project to date. Independently constructed and operated by BASF, the total investment amounts to approximately 10 billion euros. The project is located in Zhanjiang, Guangdong. Upon completion, the Zhanjiang integrated site will become BASF’s third-largest production base in the world, after Ludwigshafen in Germany and Antwerp in Belgium. The plant’s products are suitable for various durable applications, including pipes, specialty films, and blow-molded components for household and industrial chemical containers, mainly targeting the South China market. On February 5, 2025, Lin Hanping, President of BASF’s Major Projects in Asia, stated that the core facilities of the BASF Zhanjiang integrated site are progressing steadily and are planned to start production by the end of 2025.

2. HDPE will continue to be the key area of capacity expansion in the next five years.

PolyethylenePolyethylene (PE), one of the world's most widely produced chemical products, is a core component of the petrochemical industry and holds a pivotal position in the national economy. Compared to other PE categories, HDPE offers advantages in product added value and market competitiveness, prompting many petrochemical enterprises to make it the core focus of their capacity expansion plans.

In the next five years, driven by strong market demand and strategic corporate planning,HDPE will undoubtedly become the most concentrated area for capacity expansion in the polyethylene industry, and the rapid growth of its production capacity will profoundly impact the supply-demand pattern and competitive landscape of the entire industry. The following is a detailed review of these upcoming new capacity projects.

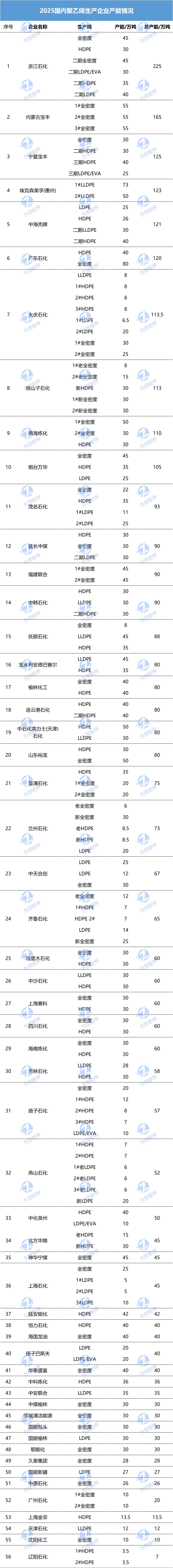

Attached:2025 Domestic Polyethylene Production Enterprise Capacity Overview Table

Source: Polyolefin People, China Chemical Information Weekly, SDIC Futures Research Institute

Editor: Yun Shimeng (Carrie)

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track