Investment of 2.3 billion, Kersen New Materials' 1 million tons polyester chip project announced

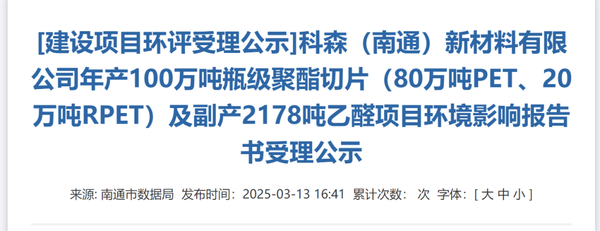

Recently, the Nantong Data Bureau released the acceptance announcement of the environmental impact report for the project by Kersen (Nantong) New Materials Co., Ltd. to produce 1 million tons of bottle-grade polyester chips (800,000 tons of PET and 200,000 tons of RPET) annually, along with 2,178 tons of acetaldehyde as a by-product, which has attracted widespread attention within the industry.

The project is grand in scale, constructed in two phases in an orderly manner.

The project construction site is located on the south side of Latitude Road 2 and the west side of Longitude Road 2 in the Yangkou Port LinGang Industrial Zone, Rudong County, Nantong City, Jiangsu Province, with an area of 138062.66m². The total investment of the project is 234023 million yuan, of which about 11250 million yuan is invested in environmental protection, accounting for 4.8% of the total investment.

The proposed project aims to have a total annual production capacity of 1,000,000 tons of bottle-grade polyester chips (800,000 tons of PET and 200,000 tons of RPET) and 2,178 tons of acetaldehyde as a by-product, constructed in two phases. The first phase has a total investment of 102,676 million yuan, which will include the construction of 2 PET production lines with an annual capacity of 200,000 tons each (including esterification units and polymerization units), 1 set of acetaldehyde recovery unit (with an annual capacity of 908.3 tons for the first phase), and corresponding utility and auxiliary facilities. The second phase, with a total investment of 131,347 million yuan, will add another 2 PET production lines with an annual capacity of 200,000 tons each, along with 1 new RPET production line with an annual capacity of 200,000 tons (including bottle flake recycling units and polymerization units), and supporting utility and auxiliary facilities. After the completion of the second phase, the total annual production of acetaldehyde across the entire plant will reach 2,178 tons.

Advanced technology empowerment, leading industry development

On the technical level, this project is full of highlights. The PET production facility adopts proprietary technology from Oerlikon Barmag Huitong (Yangzhou) Engineering Co., Ltd. (referred to as: OBHE), providing a solid guarantee for product quality. The de-aldehyding equipment accompanying the PET production uses patented technology from the construction unit, KOKSAN Group, replacing conventional nitrogen with compressed air for de-aldehyding of high-viscosity chips during the polymerization stage, significantly reducing operating costs and energy consumption, with evident technological advancement.

And the RPET synthesis process also adopts the patented technology of KOKSAN Group, chemically glycolyzing the purchased fragmented bottle chips, and then repolymerizing to produce high viscosity chips (IV=0.820), which are ultimately fed into the unique de-aldehyding device of KOKSAN Group for de-aldehyding treatment, achieving the regeneration of fragmented bottle chips, which is a first in the country. This innovative technology not only helps in the recycling of resources but also aligns with the current green and environmentally friendly development concept.

Kersen Group is well-funded, creating a "super matrix"

Kesen (Nantong) New Materials Co., Ltd. was established on September 2, 2024, as a subsidiary of the Turkish Kesen Group invested in China. As a leading enterprise in the green packaging industry chain in Central and Western Asia, the Turkish Kesen Group mainly serves more than 100 countries in North Africa, the Middle East, Western Asia, and Europe, supplying food-grade polyester packaging products. Its cooperative clients include globally renowned beverage and oil producers such as Coca-Cola, Pepsi, and Nestle.

In November 2024, the Kersen Group invested $710 million, planning to build a 2.2 million ton "green polyester new material" project in five phases. Among them, the first phase's two production lines with an annual capacity of 200,000 tons of bottle-grade polyester chips have attracted much attention. This is also the first production line in the country to use the liquid-phase viscosity-increasing one-step process route for producing bottle-grade polyester chips. After production starts, about 1,000 tons of PTA raw materials will be needed every day.

According to the project schedule, the first phase is expected to complete the foundation excavation in April, start the main construction at the end of the month, top out the polyester building in August, and deliver for installation by the end of September. The entire project is scheduled to be completed and put into operation by June next year. After reaching full production, the project can achieve an annual output value of 2.8 billion yuan. The completion of this project will not only further improve the industrial chain layout of Kersen Group but also inject new vitality into the economic development of Nantong area.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track