Innovative Medical Unscrewing Mold Shortens Cycle Times

Innovative Rotary Mold: Shortens Cycle by 15%, Debuts at K Show Germany 2025

Mold manufacturer Siegfried Hofmann GmbH has developed a new unscrewing mold concept that reportedly reduces the production cycle by 15%. The company will demonstrate this technology at the 2025 K Show in Germany (October 8-15, Düsseldorf, Hall 13, Booth C10).

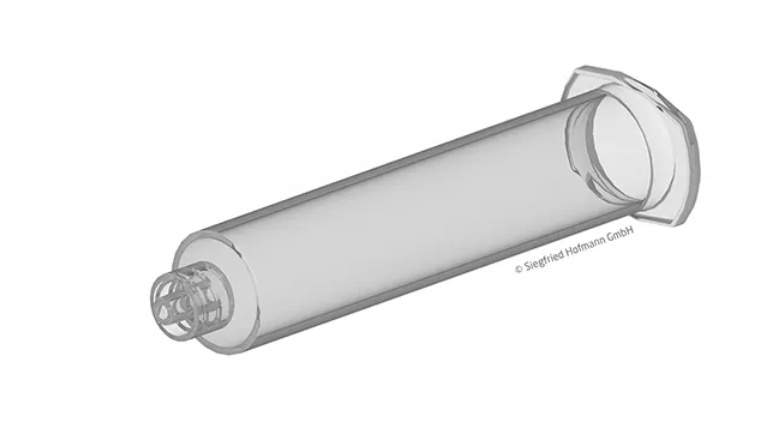

The Luer lock syringe barrel will be molded on-site at the K 2025 showroom. Image provided by Siegfried Hofmann GmbH.

Simultaneously unscrew and open the mold to achieve "zero auxiliary time."

A mechanical innovation enables the unscrewing action to be completed simultaneously during mold opening, without the need for an additional motor, rack, or programming. According to the company, it can achieve "zero auxiliary time." This new eight-cavity mold, specifically designed for producing Luer lock medical syringe barrels, will be unveiled at the 2025 K Show in Germany.

Optimize material injection and cooling to further enhance efficiency.

In addition to utilizing the unscrewing process, Hoffmann’s engineers, leveraging decades of design experience and simulation technology, have reduced the number of injection gates from two to one while meeting the stringent burr-free requirements of medical device OEMs. At the same time, a highly efficient near-contour cooling system has been added to further shorten the production cycle.

Long-term dimensional accuracy to ensure stable production.

This multi-cavity mold features long-term stability in dimensional accuracy, high consistency across cavity products, and low maintenance requirements. This is attributed to its system using corrosion-resistant and wear-resistant mold steel, combined with short-term plasma nitriding treatment of threaded cores and a robust diamond-like coating, providing reliable protection to key areas. This ensures stable production processes and permanently stable product dimensions. Additionally, an optional spare parts package and comprehensive after-sales service are available.

Exhibition Presentation Information

This high-speed multi-cavity mold will be demonstrated live on an all-electric injection molding machine at the 2025 K Show in Germany.

Siegfried Hofmann GmbH, a family-owned company headquartered in Lichtenfels, Germany, employs over 250 people and provides innovative solutions in injection mold manufacturing, mechanical engineering, and automation for clients worldwide. The company primarily serves the automotive, medical, and multi-cavity product industries.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track