Innova global debuts at k 2025: Innovative Injection Molding Solution Opens New Chapter in Smart Manufacturing

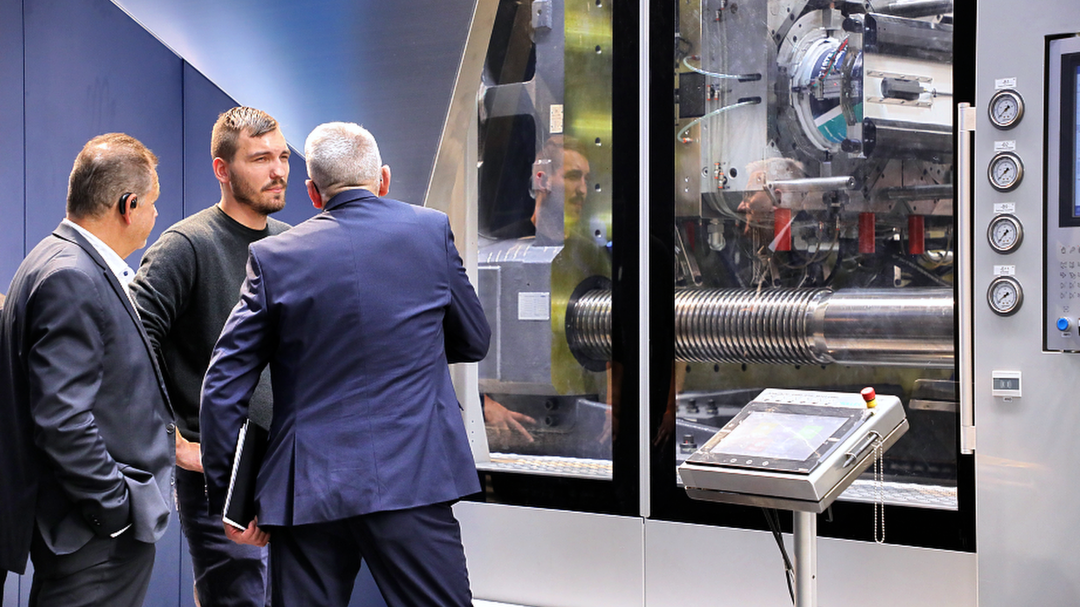

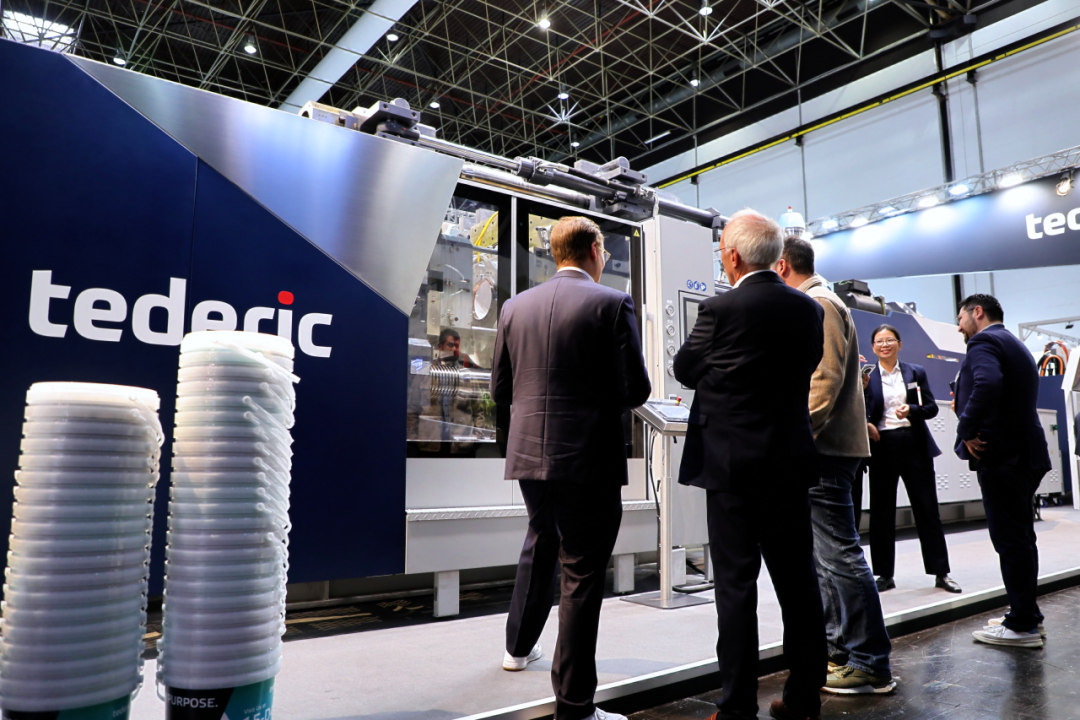

On October 8th, German time, the highly anticipated K 2025 International Trade Fair for Plastics and Rubber opened grandly at the Düsseldorf International Exhibition Center in Germany. As a leading manufacturer of injection molding equipment, Tederic showcased its new product INNOVA and three high-end injection molding solutions at booth D40 in Hall 15.INNOVATE WITH PURPOSE. SMARTER, GREENER, TOGETHER"With the theme of 'Opening a New Chapter in Intelligent Manufacturing'."

01.

Global Launch

INNOVA series makes a grand debut at K 2025.

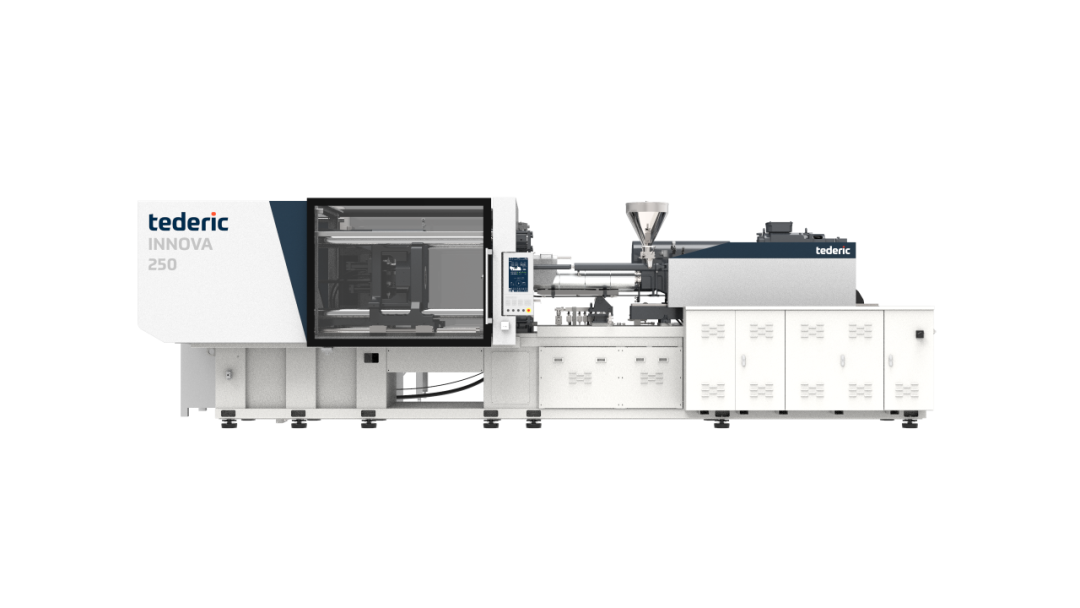

As a brand-new product specifically designed for thin-walled packaging injection molding, the INNOVA series combines speed, intelligence, and stability, redefining the efficiency and flexibility of packaging production lines with a new concept.

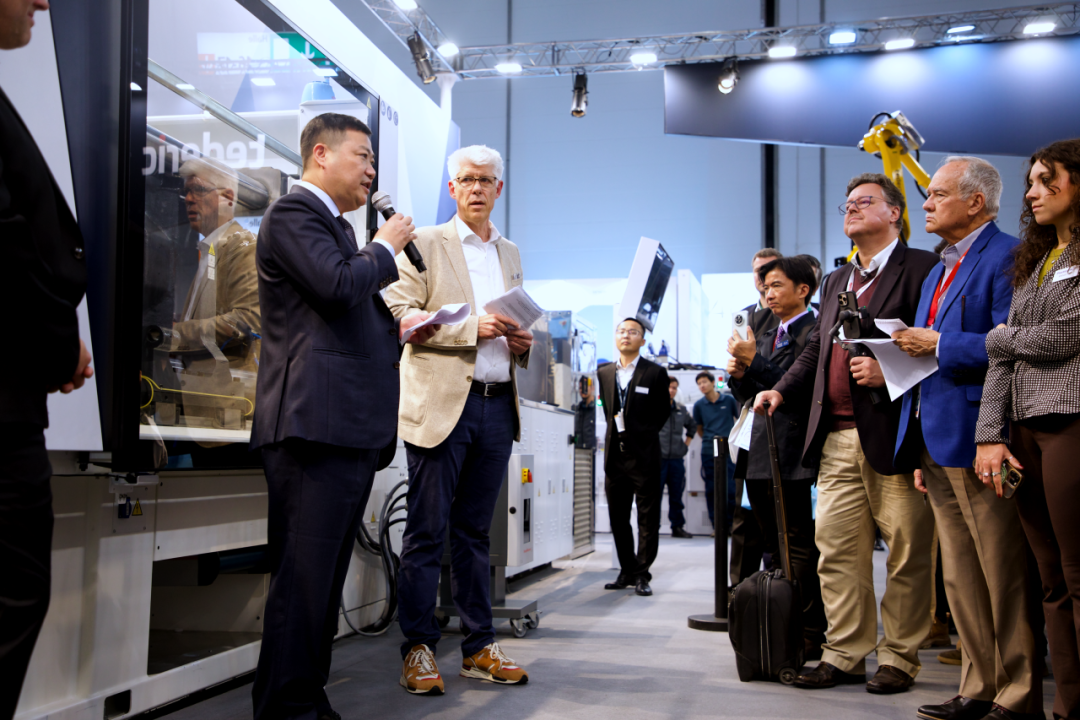

On the first day of K 2025, Terry officially announced the global launch of the INNOVA series, and simultaneously introduced..."1 out of 24 bottle caps high-speed overall solution"The live demonstration. The launch event was packed with people, attracting a large number of professional attendees. This marks a strong opening for Terri to showcase its overall strength in "Equipment + Ecology + Data" to the industry.

In Terry's 23-year development history, INNOVA is our successor...TR、DT NEOThe fourth-generation product series launched after the NEO series. It has been only five years since the NEO series was launched, and its development cycle was a mere four years. Such efficiency marks a dual leap in our R&D speed and product quality. It will help us better meet the production needs of the global packaging industry," said Mr. Zheng Jianguo, Chairman of Tairy, in a speech to the media and audience.

"With its electro-hydraulic hybrid technology, INNOVA brings sustainable advantages to the packaging industry, ensuring efficient production while significantly reducing energy consumption. Its robust structural design ensures high-performance output and extends the lifespan of equipment and molds," said Dr. Daniel Ammer, Vice President of the German R&D Center at the press conference. "At the same time, the accumulator closed-loop control injection system of this equipment can achieve up to"700 mm/s The injection speed and achieve precise repeatability," Ammer added.

The press conference attracted on-site coverage from more than a dozen major industry media outlets from countries such as Germany, the United States, and Italy. During the Q&A session, the media asked questions about product application scenarios, the global service network, and Terri's future strategy. The Terri technical team responded to each question, resulting in in-depth exchanges and frequent interactions, fully demonstrating Terri's confidence in its products and services.

After the press conference, the media and customers gave high praise. A journalist from Germany stated, "The launch of INNOVA shows us new possibilities for injection molding packaging equipment; it is a groundbreaking product." An industry customer from Europe commented directly, "This equipment will significantly enhance the capacity and flexibility of packaging production lines, and we are looking forward to further cooperation with Tech-Long."

Partners

02.

Overview of the Plan

Two major automation solutions are making their debut.

The NEO series has also been newly upgraded. Focusing on core application scenarios such as automotive accessories and logistics packaging, Tairui has launched two representative solutions, showcasing its comprehensive delivery capabilities in "equipment + production + service."

NEO·H1100ultraX

High-speed paint bucket turnkey production unit

2+2 chamber,3.58sDry cycle to achieve integrated molding and high-cycle production of 14L round paint buckets with handles.

In-Mold Labeling (IML) + Automatic StackingLabels, molds, and automation systems are deeply integrated to provide true "plug-and-produce" turnkey delivery capability.

Partners

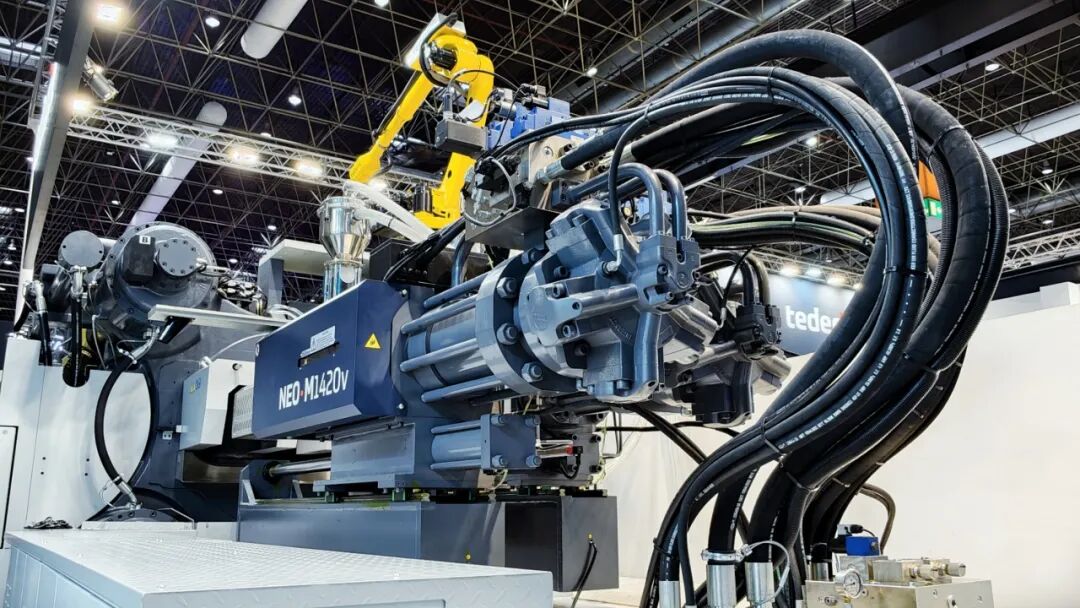

NEO·M1420v

Multi-component automotive D-pillar cover high-gloss injection molding solution

Technical solution comprehensive upgrade. Dual-color high-gloss forming with one out of two, achieving precise and efficient integrated injection molding to meet the automotive industry's strict requirements for appearance and tolerances.

Fully automated production unit, equipped withMultiMoldTM Spinsure®️-VTerry's two major self-developed processes achieve a short cycle of 70 seconds and high-stability production.

Partners

03.

Digital linkage

Tederic×INCOE Booth Live Connection

At the INCOE booth, a TedericNEO·E160The injection molding machine showcases hot injection technology and is connected in real-time with the Tederic booth. Through remote expert diagnostics and technical support, it presents the "equipment as a service" model, demonstrating efficient production and service capabilities empowered by digitalization.

The exhibition is ongoing! We welcome global customers and partners to visit the Terui booth at Hall 15, D40, to personally experience the above innovative solutions. During the rest of the exhibition, the Terui technical team will provide on-site one-on-one technical exchanges and solution consultations to discuss the future of smart manufacturing with you.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track