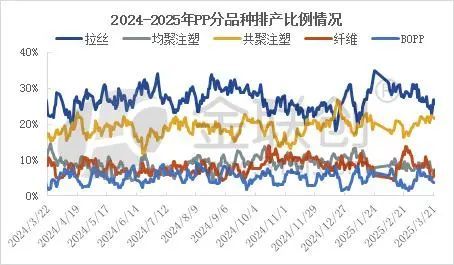

In the early spring of 2025, the covert battle for PP production scheduling by variety: Filament "lying flat," impact copolymer "intense competition."

The ranking proportion of PP product varieties affected significantly by the maintenance equipment and seasonal demand fluctuations varies distinctly; let's look at the production ranking situation of PP across different product varieties in spring 2025.

Data source: JLC (Jinlianchuan)

In March 2025, the PP market will mainly exhibit a weak fluctuation, and as of March 21, the mainstream price of extruded PP fibers ranges from 7180 to 7520 yuan per ton. In the eastern region, the mainstream price of extruded PP fibers is from 7250 to 7460 yuan per ton; in the southern region, it is from 7280 to 7520 yuan per ton; in the northern region, it ranges from 7180 to 7400 yuan per ton. However, the ranking proportion of PP production varieties is significantly differentiated due to differences in maintenance equipment inspections and seasonal demand fluctuations. Take a closer look at the production ranking situation of PP various grades at the beginning of 2025.

According to JLC, as of March 21st, the average production ratio for wire drawing in March 2025 was 27.08%, down 2.26 percentage points month-on-month. The spring maintenance of production facilities in 2025 is approaching. (Ningbo), Zhongjing Petrochemical, Pucheng Clean Energy and other production units are shut down for maintenance. The production line of Zhongjing Petrochemical in Ningbo, which mainly produces monofilament with large capacity, is undergoing maintenance shutdowns, resulting in reduced production of monofilament, with its production ratio dropping to the lowest level of 22.54% this month. Under the continuous stimulation of policies during the Two Sessions and the new-for-old policy, the production ratio of copolymer injection molding in March is showing an upward trend, with intense internal competition in copolymer injection molding. The average production ratio in March was 21.07%, up by 2.14 percentage points from the previous period. Upon closer examination of different categories within copolymer injection molding, low melt and high melt copolymers have shown significant increases, rising by 1.19 percentage points and 1.34 percentage points respectively.

From the production scheduling characteristics of other varieties, the average production scheduling ratio of homopolymer injection molding in March was 8.06%, a month-on-month decrease of 0.85 percentage points. This was mainly due to the lack of traditional peak season characteristics, slow growth in downstream daily necessities orders, and narrowing price differentials between homopolymer injection molding and drawing. Fibers have excellent wear resistance, corrosion resistance, and high-temperature performance, making them suitable for manufacturing clothing, carpets, curtains, etc. With the arrival of spring and warming weather, the average production scheduling ratio of fibers in March increased by 0.79 percentage points month-on-month to 8.03%. The production scheduling ratio of BOPP films fluctuated slightly, but demand was constrained by the limited receiving capacity of downstream factories, leading to insufficient new orders. The average production scheduling ratio of BOPP films was 5.22%, with a small month-on-month increase of 0.55 percentage points.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track