Humanoid Robots’ “Last Inch” Barrier Broken Open by Players in China

As humanoid robots move from the lab to factories and homes, the bottleneck often lies not in "whether they can walk," but in "whether they can grasp." The dexterous hand, as the "nervous end" of the robot, not only accounts for one-fifth of the total cost but also directly determines whether the robot can hold an egg, grip a cup securely, unscrew a bottle cap, or even perform minimally invasive surgery. This hand, which integrates precision mechanics, flexible electronics, and AI, is the true "last centimeter" of robot commercialization.

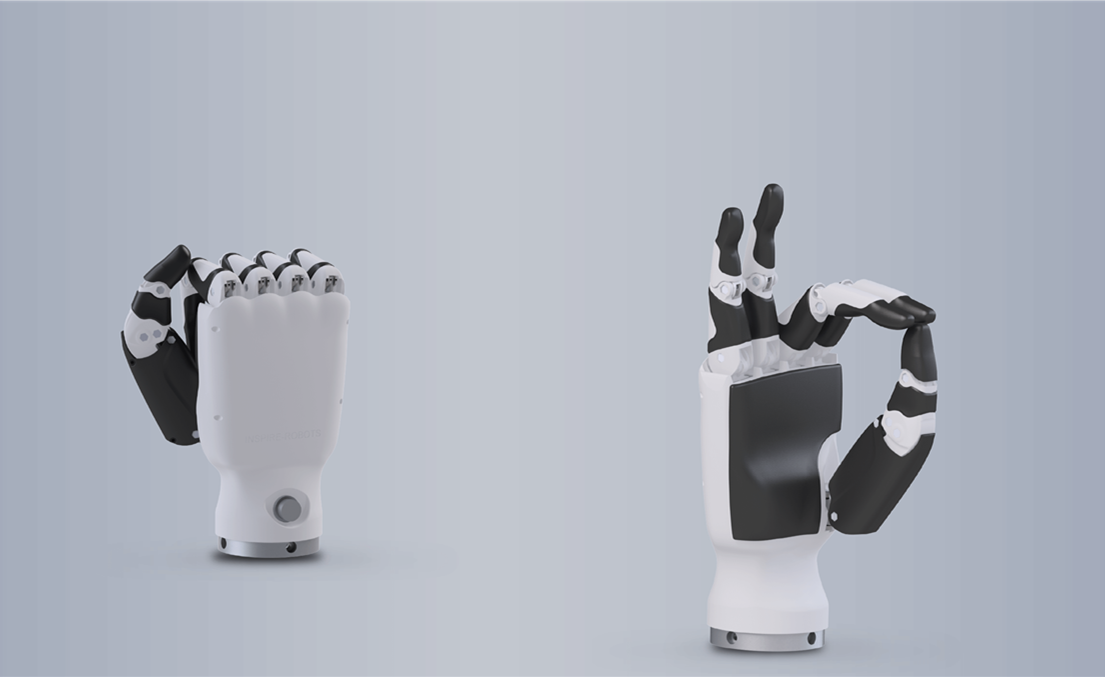

Today, as the humanoid robot boom heats up, the dexterous hand industry is also on the verge of large-scale expansion. But how to balance high versatility with low cost? Should the priority be to mimic the functions of the human hand or its appearance? These questions are making this emerging sector both exciting and complex. Chinese players have already presented unique answers in this competition.

The rapid rise of domestic dexterous hands

The significance of a dexterous hand for a robot is akin to that of hands for a human—an effective dexterous hand can not only perform basic tasks like shaking hands and grasping objects, but also maneuver into precision instruments to turn tiny screws, and even assist surgeons in picking up sutures thinner than a strand of hair on the operating table.

In this field, the global market had long been characterized by "foreign leaders and domestic followers," but now Chinese players have turned the gap into a "price gap."

Image source: Tesla

Foreign companies, having started earlier, generally possess more mature technologies. Take Tesla's Optimus robot as an example: its dexterous hand technology has undergone multiple iterations in just a few years, with the degrees of freedom increasing from 11 in Gen1 to 22 in Gen3, along with comprehensive upgrades in actuation, transmission, and sensing. The dexterous hand from the UK’s Shadow Robot even reaches 24 degrees of freedom.

However, these "top students" also face a headache: dexterous hands are not only prohibitively expensive but also hard to obtain. The prices for dexterous hands from UK’s Shadow and Germany’s SCHUNK generally exceed $100,000, and one has to wait 6 to 12 months to get them—making large-scale popularization impossible.

In contrast to the domestic situation, taking advantage of the momentum of humanoid robots, along with a complete industrial chain and huge market demand, companies in the dexterous hand sector have progressed from "following" to "keeping pace" and even leading in certain areas. According to relevant statistics, by July 2025, the number of dexterous hand companies in China has exceeded 60, capturing half of the global market. Moreover, these players have taken different routes, each with their own unique strengths.

According to differences in corporate background and business models, domestic dexterous hand players can be roughly divided into three categories:First, the "vertical new forces" specializing in dexterous hands.For example, robots such as "Time Robot," "Clever Hands," and "Smart Intelligence" have transformed foreign "luxury goods" into "industrial products."

Image source: Yinshi Robotics

As one of the earliest companies in China to achieve commercial mass production of dexterous hands, the RH56DFX series dexterous hand from Qintai Robot features a linkage drive, with 12 active degrees of freedom and a positioning accuracy of up to 0.2mm, weighing only 540g. It has been widely used in research and industrial fields.

According to official data, in 2023, the cumulative sales of humanoid robot dexterous hands by Yinshi Robotics surpassed one thousand units. Driven by the boom in humanoid robots in 2024, the company sold nearly 2,000 dexterous hands, and sales further exceeded 4,000 units in the first half of this year.

Lingxin Qiaoshou relies on "high degrees of freedom + low prices" to capture the market. The company's LinkerHand dexterous hand products have covered multiple product series. Among them, the L10, L20, and L30 models are high-degree-of-freedom, high-performance dexterous hands that incorporate various drive modes including linkages, wire drives, and direct drives, each offering 20 or more degrees of freedom. However, their prices are significantly lower compared to overseas manufacturers—the LinkerHand L10 and L20 are priced at 19,999 yuan and 49,999 yuan respectively.

According to Su Yang, co-founder and chief AI architect of Lingxin Qiaoshou, the monthly sales of Lingxin Qiaoshou's products such as Qiaoshou have reached over a thousand units, accounting for more than 80% of the market share in China and nearly 50% of the global market share.

Second, the "ontological faction" that develops dexterous hands in-house while making complete machines.The companies represented are Zhiyuan and Yushu Technology, which primarily focus on the core development of humanoid robots. They conduct independent research and development of dexterous hands as a key component of the robot's body, as "having one's own hand to match one's own arm" is essential for achieving the harmony of "grabbing when desired, and holding when needed."

In mid-August, Zhiyuan Robotics officially released the OmniHand2025 series of dexterous hands, including the "Agile Model" for interactive services and the "Professional Model" focused on specialized tasks. The Agile Model features 16 degrees of freedom, with a suggested retail price of 14,800 yuan. The Agile Tactile Model is initially priced online at the same 14,800 yuan, originally priced at 19,800 yuan. The Professional Model features 19 degrees of freedom.

The Dex5-1P dexterous hand from Unitree Robotics uses gear transmission and has 20 degrees of freedom. While maintaining high flexibility, it achieves a relatively high load capacity, with a grip force of 3.5kg in the vertical direction and 4.5kg in the horizontal direction.

It is worth noting that for Zhiyuan and Yushu, the self-developed dexterous hand not only allows for more customized development based on the overall machine requirements, achieving deep collaboration and optimization between the hand and arm, as well as between the hand and the entire machine, thus enhancing the overall performance of the robot, but also enables better cost control.

3. Enterprises crossing over from other fieldsCompanies such as Suteng Juchuang, Zhaowei Electromechanical, and Leadshine Intelligent, originally engaged in LiDAR and micro-drive technologies, have now ventured into the field of dexterous hands. In doing so, they have brought the advantages of their original expertise with them, becoming "slash professionals."

As a leading player in the field of LiDAR, RoboSense released its first-generation dexterous hand as early as 2024. Earlier this year, the company officially launched the second-generation dexterous hand, Papert 2.0. It is reported that Papert 2.0 has 20 degrees of freedom and is equipped with 15 sets of force sensors on the fingertips, finger pads, and palm. It can carry a load of 5 kilograms and perform complex operations. This product is expected to be mass-produced within this year.

Image source: RoboSense

Overall, the current domestic dexterous hands are showing two major trends: continuous improvement in degrees of freedom and rapid reduction in costs.

In terms of degrees of freedom, early dexterous hands typically had around 6, while current mainstream products have generally increased to 12-20 degrees of freedom, increasingly approaching the number of degrees of freedom of the human hand—which ranges between 21 and 27, depending on the specific calculation scope.

In terms of cost, compared to the hundreds of thousands or even millions required overseas, the cost of dexterous hands in China has already dropped significantly. Going forward, as related technologies rapidly mature and the industrial chain continues to improve, the cost of dexterous hands is expected to decrease even further.

Chao Zhou, founder and CEO of Agile Robotics, has publicly stated that in the next 2-3 years, the cost of highly dexterous robotic hands will be reduced to the range of ten thousand yuan, making the technology more accessible to a wider range of industries.

Su Yang, co-founder of Lingxin Qiaoshou, even stated that the company has the capability to further reduce the price of Lingqiaoshou, expecting to lower it to below 500 yuan within three years, or even within one year.

Large-scale mass production still requires multiple games.

During the development of Tesla's humanoid robot Optimus, Tesla CEO Elon Musk admitted that the development of the dexterous hand could account for half of the entire machine's development difficulty and engineering workload.

Behind this statement lies the major challenge of transitioning dexterous hands from the laboratory to mass production: to create a highly versatile industrial-grade dexterous hand, it is necessary not only to integrate technologies such as precision mechanics, force control algorithms, and multimodal perception, but also to find a balance between "flexibility, load capacity, and cost control"—a hurdle that all manufacturers must face.

For robots, pursuing greater flexibility usually means increasing the degrees of freedom of dexterous hands, which is why the current major players are all striving to develop high-degree-of-freedom dexterous hands.

However, the increase in degrees of freedom is not without cost; it often comes with high expenses, high failure rates, and increased weight.

First, each degree of freedom requires an independent drive unit, which directly leads to a linear increase in cost. Second, more motors and transmission components also mean higher system complexity and potential failure points, which can to some extent reduce the reliability of the product. Furthermore, components such as motors and reducers have a certain weight; integrating them inside the palm or fingers will significantly increase the weight of the dexterous hand itself, thereby affecting the robot's dynamic response speed and operational accuracy.

So, having more degrees of freedom is not always better; instead, a trade-off must be made between being “more flexible” and being “cheaper, lighter, and more reliable.”

The load capacity and flexibility of dexterous hands are also a pair of contradictions in the design process. To achieve high load capacity, more powerful motors and sturdier transmission structures, such as linkage mechanisms, are usually required. However, these rigid transmission components tend to be heavier, which can limit the range of motion and flexibility of the fingers.

On the contrary, to achieve high flexibility, such as soft grasping that mimics a human hand, flexible transmission methods like tendon-driven systems are more suitable. However, tendon-driven systems generally have lower load capacity compared to rigid transmissions and also face issues related to wear and precision. Therefore, when designing dexterous hands, it is necessary to make a choice between load capacity and flexibility based on specific application scenarios. For example, dexterous hands used for industrial handling may prioritize load capacity, whereas those used for medical surgery require higher flexibility.

So the design of dexterous hands is by no means a "one-size-fits-all" approach; it depends on the scenario: industrial handling requires the ability to bear heavy loads, while medical surgery demands high flexibility.

Image source: Lingqiao Intelligence

This raises another question: between three-fingered and five-fingered designs, which is the optimal solution for robotic hands, especially humanoid robots? Currently, there is no consensus on this issue, as each design has its own advantages and disadvantages and is suited to different tasks.

In the field of industrial automation, many tasks are relatively simple, such as grasping, placing, and assembling, and do not require high flexibility from dexterous hands. However, there are strict requirements for stability, speed, and cost. In this context, the industry generally considers two-finger grippers or three-finger dexterous hands to be better choices, as they not only have simple structures, are easy to control, and are cost-effective, but also have high reliability.

The five-fingered dexterous hand has greater advantages in versatility and flexibility, making it more suitable for high-value fine operations and assembly in complex and unstructured environments. Especially with the advancement of humanoid robot technology, it is now widely believed that dexterous hands are expected to become the ultimate solution.

However, while dexterous five-fingered hands are undoubtedly the "crown jewel" in the field of robotics, it is undeniable that the design and control of such products are more complex and costly. If the goal is merely to mimic the appearance of a human hand but with limited degrees of freedom, in many scenarios, some low-degree-of-freedom five-fingered dexterous hands may have certain fingers "idle," resulting in actual performance that is inferior to that of three-fingered dexterous hands.

The new generation of bionic dexterous hand Revo2 from Qiangnao Technology has only 11 degrees of freedom. When discussing the logic behind this design, a company representative stated, "We can create dexterous hands with higher degrees of freedom, but the side effects would be higher costs, higher failure rates, and greater weight. The reason we designed it this way is based on user feedback; it can accomplish over 90% of human hand activities, and the cost can be reduced to a threshold of 20,000 yuan. We believe this is a high cost-performance product."

Zhu Haohua, the CTO of Lingqiao Intelligent, even stated that many so-called "five-finger dexterous hands" on the market actually only resemble five fingers; in essence, they still replicate the functionality of three or even two fingers.

Next step: lighter, more flexible, smarter

As the humanoid robot industry accelerates, the technical approaches for dexterous hands are no longer “a hundred flowers blooming,” but are gradually converging on several clear directions—making dexterous hands lighter, more flexible, and more intelligent, evolving from “being able to grasp objects” to “being able to grasp objects precisely.”

Image source: Qiangnao Technology

For robots, a lightweight robotic arm means smaller inertia, faster response speed, and lower energy consumption, which is crucial for enhancing the overall performance of the robot. Currently, the mainstream solutions in the industry generally keep the weight of a single hand under 1 kg, with some players' new generation products even achieving weights of under 400 g.

The new generation of smart hand product from BrainCo, the BrainCo Bionic Smart Hand Revo2, is only 16cm long, similar to a human female's hand, but the entire hand weighs only 383g, equivalent to the weight of 6 eggs. Despite its small size and light weight, the Revo2 has a grip strength of up to 50N and can bear up to 20KG.

LinkerHandO6, with its ingenious and skillful design, is miniaturized and lightweight, weighing only 370g while being close in size to a woman's hand. It uses new aerospace aluminum materials in many parts, yet it can handle a load of over 30kg.

From this, it can also be seen that the use of lightweight materials is one of the important ways to achieve weight reduction in dexterous hands. Other commonly used lightweight materials for dexterous hands include magnesium alloys, carbon fiber composites, engineering plastics, etc. Among them, PEEK material is gradually being considered the core solution for achieving robot lightweighting due to its superior insulation and chemical resistance compared to ordinary metals.

Greater flexibility means higher degrees of freedom, which is the foundation for achieving precise operations. Currently, the number of degrees of freedom in mainstream dexterous hands is increasing from 6-11 to 12-20 or even higher. Tesla's Optimus Gen 3 has achieved 22 degrees of freedom, Zhiyuan's OmniHand 2025 professional model has 19, and Lingxin's Linker Hand L30 boasts a total of 25 degrees of freedom, all representing the current high level in the industry.

In addition to enhancing freedom of movement, the upgrade of the transmission system also provides a solid foundation for performance optimization of the dexterous hand.

Currently, tendon drive and linkage drive are two mainstream solutions. Tendon drive can achieve long-distance power transmission, allowing more space for fingers and is lightweight, but it has issues with wear and precision. Linkage drive has high stiffness and can handle larger loads, but its structure is complex and heavier. In the future, composite drive solutions are expected to become mainstream. For example, Tesla's Optimus Gen3 innovatively uses a "screw + tendon" structure. Huolong Securities believes that under Tesla's leadership, the "screw + tendon" composite drive solution is likely to become mainstream.

Image source: Yinshi Robotics

The continuous evolution of perception capabilities is also a key focus for the next stage of dexterous hand upgrades.

In the past, dexterous hands mostly had force sensing capabilities, such as knowing that something was being grasped, but they couldn't determine what was being grasped or if the force was sufficient. Now, they are developing towards "tactile + visual" multimodal sensing, especially with tactile sensors, which are quickly becoming standard. It's akin to equipping dexterous hands with "fingertip touch," allowing them to sense force, temperature, and texture. Furthermore, the trend is shifting from "installing sensors only at the fingertips" to covering the entire hand with an array of tactile sensors as "electronic skin," enabling the entire hand to have a "sense of touch."

This fully hand-like electronic skin can provide richer and more delicate tactile information, enabling dexterous hands to perceive the shape, texture, hardness, and temperature of objects, thereby achieving smarter grasping and manipulation. For example, the latest LinkerHandL20 released by Lingxin Qiaoshou has over 1,500 physical pixel points distributed across 16 areas of the palm, allowing for sub-millimeter level perception.

From precise demonstrations in laboratories to batch operations in factories, the dexterous hand industry is making a crucial leap from "technological breakthroughs" to "commercial validation." Chinese companies are rapidly breaking through in global competition by leveraging the dual advantages of "high flexibility and low cost."

In the future competition of dexterous hands, it will no longer be about "who has more degrees of freedom" or "who has a greater load capacity," but rather about "who is more suitable for the scenario": industrial scenarios require "stability and reliability + cost control," home services need "safety and flexibility + ability to perform various household tasks," and the medical field demands "precision and minimally invasive procedures + precise force control."

When dexterous hands with over 20 degrees of freedom drop to a price level of around ten thousand yuan, and when multimodal perception enables them to precisely “hold a potato chip without breaking it, and grip a power drill without dropping it,” only then can dexterous hands truly be considered the “final piece of the puzzle” for humanoid robots.

One day, we will get used to robots using flexible "hands" to help us pass things, do housework, and even assist in surgeries—when that time comes, we will remember that the starting point of this transformation was this group of Chinese players, who, with their affordable dexterous hands, tore open the gap for industrialization.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track