Huitong Shares’ Long-Chain Nylon Becomes a “Hot Seller,” Develops High-Performance PEEK and Carbon Fiber Reinforced Materials for Robots

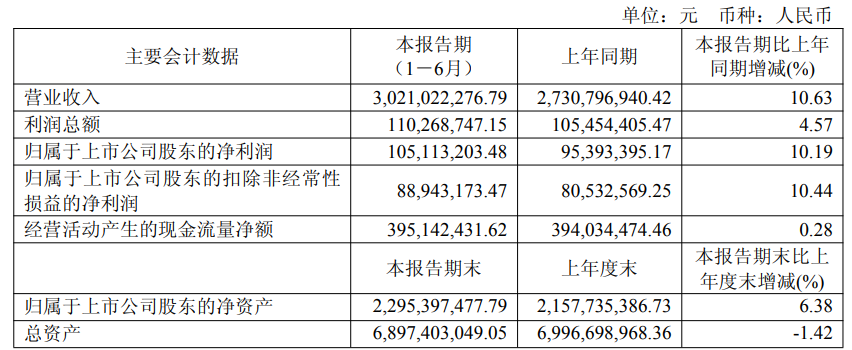

Recently, Huitong Co., Ltd. released its semi-annual report for 2025. The company achieved an operating income of 3,021.0223 million yuan, a year-on-year increase of 10.63%, and a net profit attributable to shareholders of the listed company of 105.1132 million yuan, a year-on-year increase of 10.19%. The core growth comes from the increased demand for materials supporting new energy vehicle subsystems, lightweight electric vehicle structural components, and high-temperature resistant materials for charging piles.

Overseas revenue increased by 39.03% year-on-year. Currently, the company is using its Thailand base as a starting point to expand throughout the Southeast Asian region and is gradually advancing into markets in Europe, North America, the Middle East, and North Africa. It has established a subsidiary in North America to enhance its competitiveness in the international market.

In the niche market segment, revenue increased by 48.77% compared to the same period last year. The company continues to promote the use of high-temperature nylon materials in components of consumer electronic products such as computers and mobile phones. In addition, the company's high-temperature nylon and other materials are applied to new energy charging piles, gradually opening up the charging pile market. In markets such as photovoltaics and military industry, the company's developed carbon fiber reinforced and continuous fiber reinforced materials have also been successfully applied.

During the reporting period, the specialty materials subsidiary, which primarily produces and sells long-chain nylon and other materials, entered a phase of rapid growth, with revenue increasing by 60.51% year-on-year. The company developed single-layer and multi-layer long-chain nylon pipeline materials applied in automotive thermal management systems, receiving unanimous praise from numerous customers. The developed long-chain nylon powder materials have been applied in household appliances such as dishwashers, addressing the long-standing issues of dishwasher manufacturers being constrained by the supply price and lead time of imported powder materials. To tackle the cooling challenges of liquid cooling systems for AI data servers, the company introduced long-chain nylon pipelines and fittings solutions and has cooperated with related manufacturers. Additionally, the company developed long-chain nylon flame-retardant corrugated tubing solutions, applied in robotic-related pipeline materials.

In the upstream production field of PCR materials, joint ventures with upstream PCR companies have been established in the East China and South China regions to set up production bases. This has integrated the entire industrial chain of consumer goods from "reuse-dismantling-crushing-sorting-pelletizing-modification" and continuously expanded the use of modified PCR materials. It covers PCR materials such as bucket-grade PP, black PP, gray-white HIPS, gray-white ABS, and black ABS.

During the reporting period, the company increased its capital in Huifeng Environmental Technology (Anhui) Co., Ltd.With an annual production capacity of 50,000 tons, further deepening its layout in the PCR field, the joint venture production base Guangdong Zhongyin Plastics Co., Ltd. has an annual production capacity of 100,000 tons. In the downstream application field, the company collaborates with car manufacturers and high-quality automobile dismantling plants to co-create recycling cases, establishing a "Car To Car" recycling model; in addition, it also partners with the green recycling teams of large domestic home appliance enterprises to develop the dismantling and circular reproduction industry chain, achieving end-to-end original-grade recycling utilization in the home appliance industry.

In the field of robotics, several materials have been developed, including high-rigidity carbon fiber reinforced materials, high-performance PEEK materials, and continuous fiber composites, to meet customers' application needs in different scenarios. On the other hand, the company has developed a range of materials focused on "flexible skin," including injection-molded skins and high-silicon-content food-grade elastomer materials. Additionally, the company continues to interact with industry enterprises to provide material solutions, focusing on structural components such as optical sensors, tactile sensors, millimeter-wave radars, and aesthetic materials for appearance.

In the low-altitude economy sector, we develop material solutions including lightweight PC materials and ultra-high modulus carbon fiber reinforced composites to meet customer requirements.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track