Huitong Shares Deploy Thermoplastic Composites to Create Performance and Value-Optimized Solutions for Customers

Driven by global industrial upgrading and the "dual carbon" goals, competition in the field of new materials has become a key battleground for major powers. As the "rising star" in the new materials sector, thermoplastic composites, with their outstanding advantages of lightweight, high performance, and environmental friendliness, are becoming a core supporting material for strategic emerging industries such as aerospace, new energy vehicles, and the low-altitude economy. Huitong New Materials Co., Ltd. focuses on the domestic breakthrough of thermoplastic composites, building a full-chain value delivery system based on customers' core demands for "extreme performance, reasonable cost, and independent supply."

Thermoplastic Composites: The "Material Engine" of High-End Manufacturing

Accurately match customers' multidimensional demands.

Thermoplastic composites create value for customers from three dimensions with their unique properties.

● The perfect integration of lightweight and high performance: Compared to 6061 aluminum alloy, the weight can be reduced by more than 30%, with a 20% increase in specific strength and stiffness, and a fatigue life 100 times that of 7075-T6 aluminum alloy. This means weight reduction and efficiency improvement for aerospace customers, resulting in a leap in fuel economy; a substantial breakthrough in driving range for new energy vehicle customers; and dual enhancements in carrying efficiency and endurance for low-altitude economic aircraft customers.

● Adaptation to green and sustainable development: It has recyclable and reprocessable characteristics, addressing the environmental challenges of traditional thermosetting composites. It assists clients in the automotive, aviation, and other fields in achieving "dual carbon" goals and enhances brand competitiveness in green initiatives.

● Dual advantages of efficiency and cost: Short molding cycle, suitable for large-scale automated production, significantly reducing manufacturing costs, clearing cost obstacles for clients' industrial applications, and establishing dual advantages of price and delivery efficiency in market competition.

Global Competition and Domestic Substitution: The Strategic Significance of Huitong's Deployment

As of 2024, the global market size for thermoplastic composites has reached approximately 87.9 billion yuan and is expected to exceed the 100 billion yuan mark by 2030. However, the current market is dominated by international giants such as Solvay, Toray, and Teijin, with a very low domestic production rate. This "bottleneck" situation not only restricts the development of China's high-end manufacturing industry but also poses a threat to the security of the industrial chain.

Huitong Co.'s strategic deployment in thermoplastic composites targets this key opportunity: On one hand, technological breakthroughs enable independent control over critical materials, providing stable and secure raw material supplies for clients in the aerospace, new energy vehicle, and other sectors—completely eliminating the risks associated with import dependence. On the other hand, by breaking foreign technological monopolies and leveraging cost advantages of domestic production, the company helps clients lower material procurement barriers and enhance their product competitiveness in the global market.

Multi-domain application scenarios: Customized solutions for industry pain points.

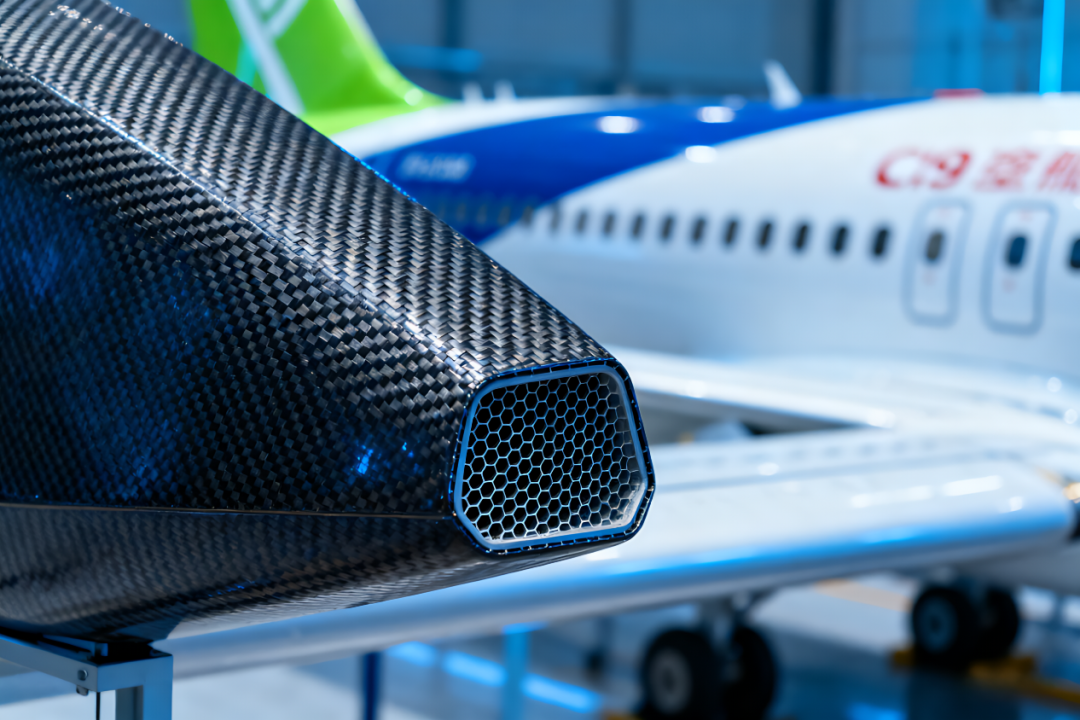

Aerospace field

Thermoplastic composite materials have broad application prospects in large aircraft such as the C919 and C929, as well as in low-altitude economic aircraft. According to research reports from institutions such as Guanyan Report Network, the C919 is China’s first civil aircraft model to use T800-grade high-strength carbon fiber composites in its main load-bearing structures. The proportion of composite materials used in the aircraft structure reaches about 12%, which can effectively reduce the aircraft’s weight and improve fuel efficiency. Huitong’s strategic layout will provide high-performance and highly reliable material solutions for customers such as domestic large aircraft and drones, thereby supporting the localization process of China’s aerospace industry.

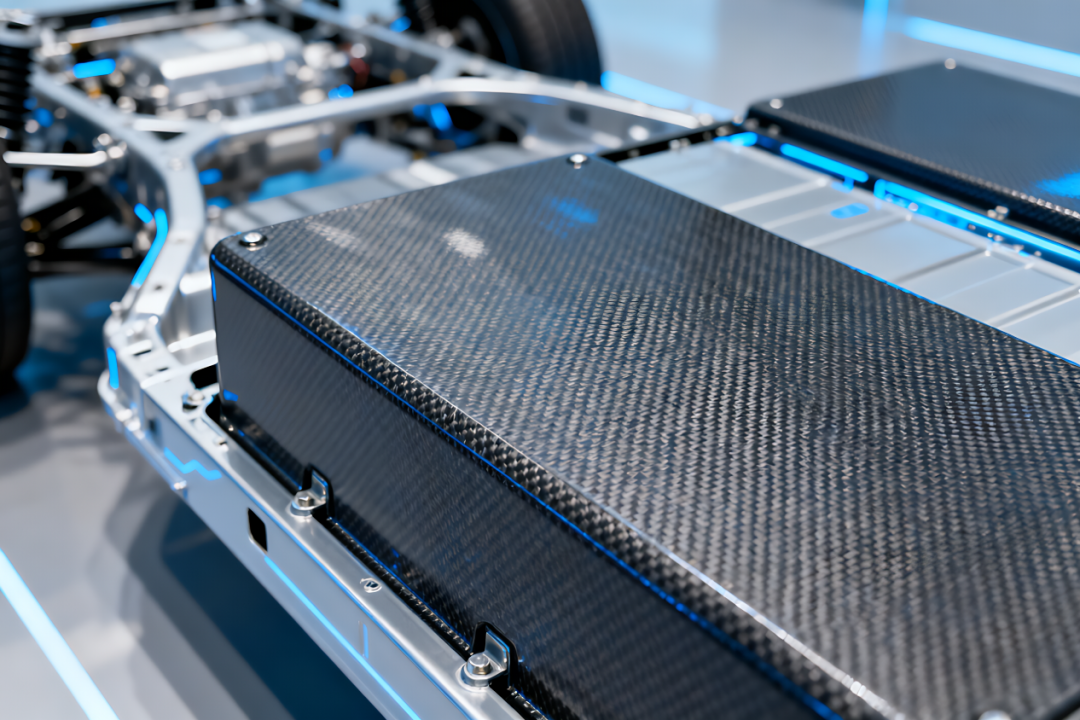

New Energy Vehicle Field

The application of thermoplastic composites in areas such as battery packs and vehicle body structures can significantly enhance the range of vehicles, making it a key material for the lightweighting of new energy vehicles. Huitong's technological breakthrough will help automotive clients stand out in the market competition characterized by "range anxiety," accelerating the market penetration of new energy vehicles.

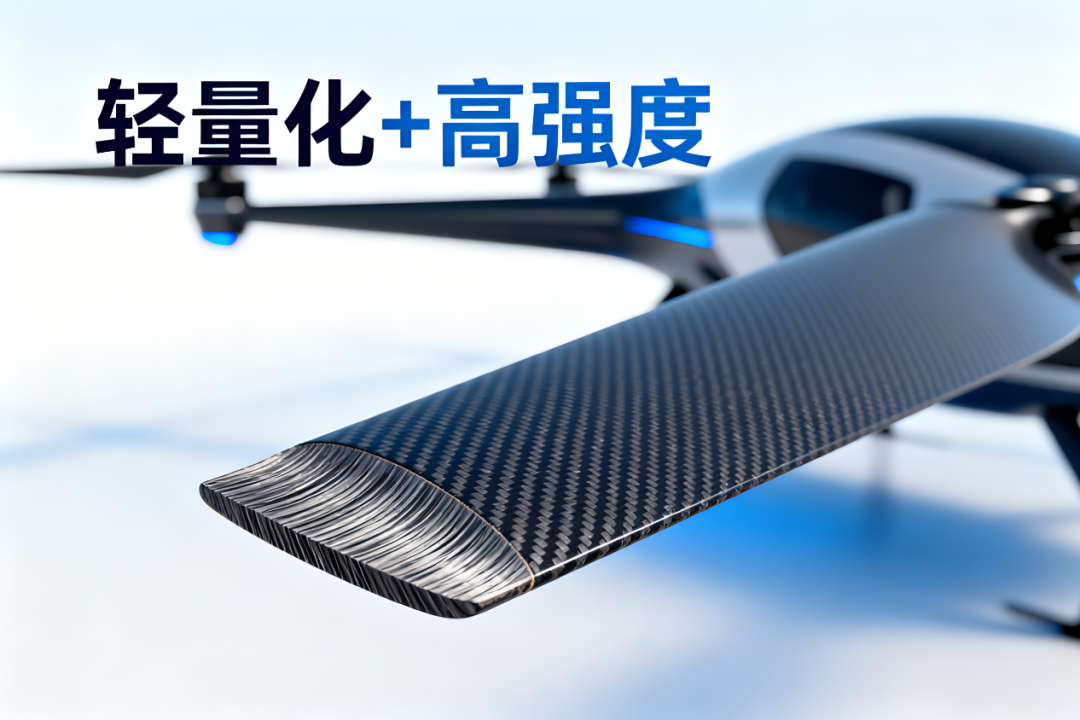

Low-altitude economy field

For eVTOL (electric Vertical Take-Off and Landing) aircraft and logistics drones, thermoplastic composites can be used in components such as the fuselage frame, wings, and rotor blades, effectively reducing weight and enhancing flight performance and aerodynamic efficiency. The integrated layout will provide clients in the low-altitude economy sector with material support that combines "lightweight and high strength," promoting the rapid development of the low-altitude economy industry.

High-end equipment manufacturing sector

In fields such as industrial robotics and precision equipment, thermoplastic composite materials can enhance equipment performance and service life, meeting the stringent material requirements of high-end equipment. Huitong's material solutions will help high-end equipment manufacturing customers improve product quality and gain a larger share in the global high-end equipment market.

Full-link Layout of Huitong: Value Extension Centered on Customer Needs

Huitong Co., Ltd. is integrating industry chain resources to build a full-chain collaborative capability covering "resin-composite materials-application components," with a focus on overcoming the bottleneck of domestic production of thermoplastic composite materials. This involves achieving full-process localization from raw materials and equipment to production processes. Essentially, this layout is a customer demand-oriented deep value delivery: in terms of performance, it provides customers with material performance "on par with international giants"; in terms of cost, it leverages localization advantages to reduce material procurement costs for customers; and in terms of supply, it eliminates "supply disruption risks" for customers through a self-controlled supply chain. In the future, Huitong Co., Ltd. will continue to delve into the field of thermoplastic composite materials, creating continuously iterating material value for strategic emerging industry clients such as aerospace and new energy vehicles, aiding China's high-end manufacturing industry in seizing the high ground in global competition.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track