How to Choose the Right Extrusion Laboratory Machine? The Nuances Are No Less Than Selecting a Factory Main Machine!

A laboratory extruder is a compact, high-precision extruder designed for material research and development, pilot production, small-scale testing, and educational purposes.

In addition, in certain specific application scenarios, laboratory extruders can also fulfill actual production tasks. For example, in the pharmaceutical industry, functional foods, as well as small-batch, high value-added, and high-performance plastics industries, laboratory extruders have become ideal production equipment due to their flexible configuration, rapid material switching, and precise control.

They are not only "testing grounds" for innovative research and development, but are also gradually becoming "production lines" for small-scale, high-precision manufacturing.

Comparison between Laboratory Extruder and Industrial Extruder

The basic principles of laboratory and industrial extruders are the same, including screw structures (such as single-screw, twin-screw, or multi-screw), as well as similar heating, cooling, drive, and control systems. However, laboratory extruders are scaled-down versions of industrial extruders. Modules such as die heads, pelletizing systems, and feeders can be flexibly configured to meet specific research objectives. Although laboratory extruders use the same materials and process parameters, their output is significantly lower.

Laboratory extruders typically process between 0.25 and 150 kilograms of material per hour, making them ideal for research and development, small-scale trials, and educational purposes. Some micro models support ultra-low feed modes, with a minimum processing volume of less than 250 grams. In contrast, industrial extruders have a much larger processing capacity, ranging from tens of kilograms to several thousand kilograms per hour, suitable for continuous large-scale production.

Laboratory extruder emphasisAccurate data collection, flexibility in process adjustments, and ease of parameter optimization., while industrial extruders focus onHigh throughput, operational stability, energy efficiency, and reduced labor requirements。

Application of Laboratory Extruders

Research and Development of New Materials and Formulation Development

The laboratory extruder plays a core role in the development and formulation of new materials, including polymer modification, functional particle development, and biodegradable compounds.

Process Parameter Validation and Optimization

Under controlled small-batch conditions, they validated process parameters such as screw configuration, temperature zones, and exhaust efficiency, laying the foundation for industrial scale-up.

Preparation and Application Validation of Small Batch Samples

Laboratory extruders are also widely used for small-scale sampling, color testing, and application performance testing of products such as masterbatches, fillers, and foamed materials.

Reactive and functional extrusion research

In reaction extrusion, the equipment supports continuous control of in situ polymerization and crosslinking reactions, making it suitable for the process development of reactive polymers.

Special Industry Material Verification

For the pharmaceutical and food industries, laboratory extruders can be used for structural optimization and molding studies of functional materials such as controlled-release tablets, polymer carriers, and nutritional granules.

Teaching and Research Practice

Laboratory extruders are important teaching tools for courses in extrusion technology and materials science at universities and research institutions, providing support for practical training and the cultivation of future engineers and technicians.

In the laboratory stage, researchers use small-scale extruders to test key parameters such as raw material ratios, processing temperatures, screw configurations, and melt characteristics. After successful process validation, the formulation and process are scaled up and tested on industrial-scale extruders, ultimately achieving stable mass production.

Therefore, the structure and principle of the laboratory extruder are exactly the same as those of the industrial-grade extruder, but it is smaller in size, lower in output, and more flexible in function. It is mainly used for precise testing and verification of formulations, processes, and material properties in a controlled environment.

In summary, the laboratory extruder serves as the foundation and validation platform for large-scale production. From small-scale trials to pilot production and then to large-scale manufacturing, each stage is built upon processes validated in the laboratory.

Why do we need a laboratory extruder?

Reduce trial and error costs

The material cost for each run of the industrial extruder is very high. Conducting small-batch tests in the laboratory can significantly reduce raw material usage and save time. After the formulation is verified, the extrusion process can proceed to industrial-scale production.

Note: Translate the above content into English and output the translated result directly without any explanation.Scaling up production is not a simple linear process. Factors such as shear sensitivity and thermal stability must be considered, as the behavior of materials can vary significantly under different screw diameters and shear rates. Laboratory extruders can provide critical reference data to support precise scale-up production.

Flexible process adjustment

The laboratory extruder supports rapid mold change, adjustment of screw sections, and modification of temperature zones, making it an ideal choice for material innovation.

Get the initial amplification parameter

The laboratory extruder provides critical data (such as pressure, torque, and melt state), which can serve as valuable reference points during the scale-up of industrial processes.

Closed R&D-Production Cycle

Even if the materials have already been validated, production fluctuations or formulation changes still require renewed laboratory simulations for adjustment.

Laboratory extruder size

Laboratory extruders are typically classified into micro, standard, and pilot scale based on size, capacity, and application. These categories are primarily defined by the screw diameter (usually in millimeters) and the overall size of the machine.

Standard Laboratory Extruder

The screw diameter of standard laboratory extruders is typically between 16 and 35 millimeters. Their dimensions are approximately 1 to 2 meters in length, with a width and height of 0.6 to 1.2 meters each. These standalone floor-type models are equipped with control panels and are widely used for material development and process validation.

Micro laboratory extruder

Length: 50-100 cm, width: 30-60 cm, height: 30-60 cm, screw diameter: 12-16 mm. Its compact design allows it to be placed on a benchtop or mobile stand. These devices are typically used for formulation screening, experiments, and educational settings. They support rapid material changes and require only a minimal amount of raw materials, making them ideal for high-frequency, low-cost testing environments.

Pilot-scale extruder

Pilot-scale extruders are typically equipped with pelletizing and cooling systems to better simulate real industrial processing conditions. Their screw diameters are usually between 25 and 45 millimeters, making them ideal for small-batch production, sampling, or pre-commercial scale testing.

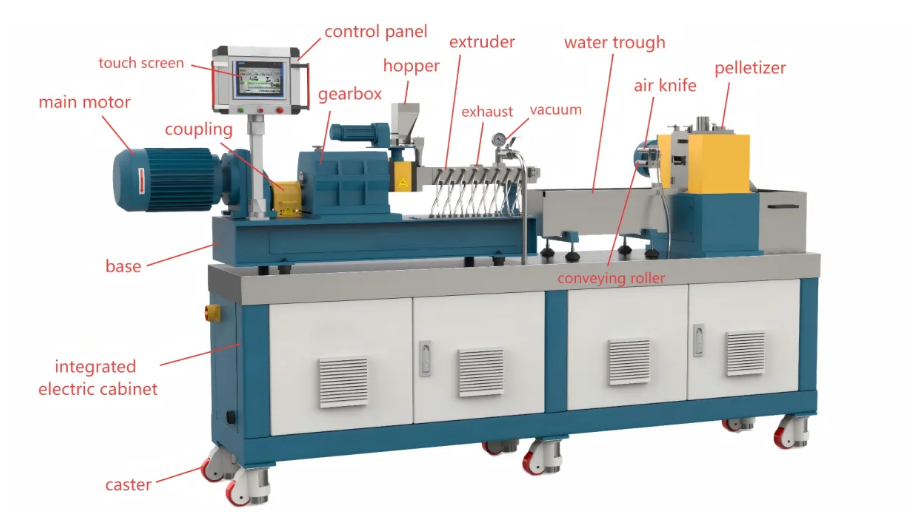

Source of the image: Cowin

How to Choose the Right Laboratory Extruder

When selecting a laboratory extruder, please carefully assess the following key factors:

1. What is the purpose of your experiment—educational use, basic research, or advanced materials development?

Which type of material will you use—thermosensitive, volatile, or chemically reactive polymers?

3. What is the required output quantity? In grams or kilograms? Will the equipment be used for pilot production or customer samples?

Does the process require advanced functions such as gas injection, vacuum devolatilization, or reactive extrusion?

5. What is your budget and available laboratory space? Do you need modular upgrade options for future expansion?

6. Is there a need to scale up in the future? Are the equipment compatible with industrial-grade module interfaces?

Key parameters to consider when selecting a laboratory extruder

1. Screw Diameter and L/D Ratio (Length-to-Diameter Ratio)

The screw diameter directly determines the sample throughput. For example, 16-20 mm is suitable for teaching and early-stage research and development; 25 mm is suitable for process validation and pilot-scale production; 35 mm is suitable for small-scale commercial production.

The typical length-to-diameter (L/D) ratio ranges from 32 to 48, which affects melting time, mixing efficiency, and residence time. A higher L/D ratio (≥40) can provide a longer processing path, making it suitable for complex applications such as reactive extrusion or highly dispersed formulations.

Suggestions: Translate the above content into English, output the translation directly, and do not provide any explanation.For complex formulas or processes that require optimization, prioritize equipment with an L/D ratio of 40 or higher.

2. Output Range

The processing speed of laboratory extruders can be as low as 0.25 kg per hour and as high as 150 kg per hour, depending on the specific model. The choice should be based on sample volume, raw material cost, and experiment frequency.

The micro extruder is ideal for high-frequency testing or expensive materials. The pilot-scale models are more suitable for customer samples, reservations, or application validation.

Suggestion: Determine the minimum sample size required and the ideal throughput range to select a machine that suits your operational needs.

3. Modular design

The modular system allows for the quick replacement of screw elements, barrels, molds, and exhaust modules to support different experimental objectives.

This is especially valuable for research and development institutions that have shared devices, frequently change parameters, or have long-term upgrade plans.

Suggestion: To achieve flexible and versatile usage, choose equipment with a highly modular structure to maximize adaptability and reduce long-term costs.

4. Control System (PLC + HMI)

A high-quality laboratory extruder should be equipped with a PLC and touch screen HMI system, capable of precisely controlling temperature, torque, pressure, and screw speed.

Data traceability and exportability are crucial for R&D reports and scale-up documentation.

Sure! Please provide the content you would like me to translate into English.Choose a system with integrated touchscreen control and real-time data logging—especially if you plan to apply for a patent, publish research results, or pursue commercial production.

5. Common Configuration Options

When evaluating system compatibility, please consider the following components:

Side feederFiller materials such as glass fiber, talc, or pigments are used.

Vacuum Exhaust:Improve devolatilization and reduce residual volatiles.

Granulation System:Choose between strand, water ring, or air cooling granulation based on your final application requirements.

Mold Design:Match the molds (flat, circular, foam, etc.) with your specific product shapes and formulas.

Sure! Please provide the content you'd like me to translate into English.Confirm target materials and process requirements in advance. Ensure compatibility to avoid costly customizations later.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track