Henan Plastics Association Visits Zhangjiagang Plastic Machinery Enterprises

Secretary of the Party Branch and President of the Henan Province Plastics AssociationDuring his visit to Zhangjiagang, Duan Tongsheng and his delegation visited several plastic machinery companies, held discussions with company leaders, exchanged views to strengthen friendships, and explored ideas for industry cooperation between the two regions.

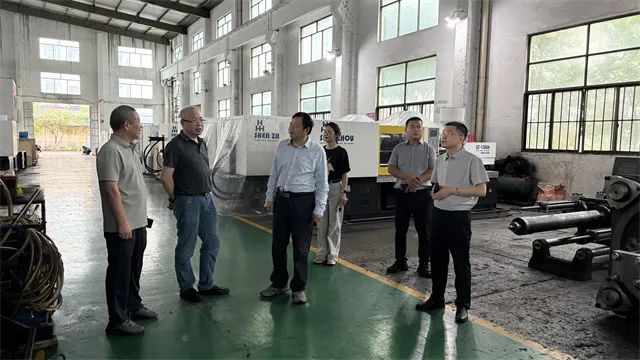

At Zhangjiagang Shenzhou Machinery Co., Ltd., Chairman Zhu Zhanzhao introduced the company's current main business, market positioning, and development plans to President Duan. They pleasantly reminisced about their close-knit experiences during their entrepreneurial journey together, revisiting the deep friendship they forged back then.

Accompanied by Chairman Zhu, the company's General Manager, rotating President of the Zhangjiagang Plastic Beverage Machinery Association Chen Changhong, Secretary-General Feng Qin, and other leaders, President Duan and his delegation visited Shenzhou Machinery's workshops for injection molding machines, mold processing, and plastic products. President Duan inquired in detail about Shenzhou's main production and business operations and invited Chairman Zhu to visit Henan when he has the time. He also expressed hope that Shenzhou Machinery's products will continue to play an important role in the development of the plastic industry in Henan Province.

Zhangjiagang Shenzhou Machinery Co., Ltd. leverages years of extensive experience in professional injection molding machine manufacturing, high-standard design, and precision processing. Utilizing imported branded hydraulic, electrical, and sealing components, the company is dedicated to producing the SZ series fully automatic computer-controlled injection molding machines and related peripheral equipment. With excellent quality, stable performance, and superior cost-performance ratio, the products maximally meet customers’ interests and needs. The high-quality and innovative products, professional and rigorous management, comprehensive technical support and services have enabled the company’s products to rapidly capture the market, selling to more than twenty provinces and cities across China, and exporting to the Middle East, Southeast Asia, Russia, Central Asia, Africa, and other regions, earning full trust and praise from customers. Awarded the ISO9001 Quality Management System Certification, the company has reached international standards in management responsibility, quality inspection, design review, production procedures, customer service, and other key aspects.

At Suzhou Tongda Machinery Co., Ltd., Chairman Xu Wenliang, who is also the President of the Zhangjiagang Plastic Beverage Machinery Industry Association, introduced the company’s basic situation to President Duan and led him to visit the newly renovated office building. President Xu briefed President Duan and his delegation on the company’s product research and development, production operations, market expansion, and future planning. President Duan expressed admiration for Tongda’s high-end positioning and its continuous leadership in the processing of plastic hollow products and related fields, as well as appreciation for the company’s achievements in technological innovation and product development.

Suzhou Tongda Machinery Co., Ltd.Founded in 1999, it is an intelligent equipment supplier focusing on extrusion blow molding equipment, integrating design, research and development, production, sales, and service. The company currently has three production bases, covering a total area of over 100 acres, with more than 400 registered employees. It produces over 1,200 sets of equipment of various specifications annually, with products and customers spread across more than 100 countries and regions worldwide.

The company has strong comprehensive strength and has ranked among the top three in the plastic machinery extrusion blow molding hollow molding equipment industry for 13 consecutive years. It is a vice chairman unit of the China Plastics Machinery Industry Association and a high-tech enterprise in Jiangsu Province.

The company consistently regards technological innovation as the core driving force, establishing a comprehensive research and development management mechanism. It possesses research and development platforms such as the Jiangsu Provincial Enterprise Technology Center, Jiangsu Provincial Extrusion Blow Molding Technology Engineering Research Center, Jiangsu Provincial Excellent Graduate Workstation, and Jiangsu Provincial Postdoctoral Innovation Practice Base. Currently, the technology center has more than 80 R&D personnel, including 1 individual from the national "Ten Thousand Talents Program," 6 with senior titles, and 15 with intermediate titles. The company has led the formulation of 3 national industry standards.

The company has always adhered to the principle of "promoting openness, inclusiveness, and mutual benefit," focusing on independent research and development of extrusion blow molding. We provide customized product solutions for global customers, striving to improve the quality of life for all employees through technology and to achieve enduring benefits for our clients through innovation.

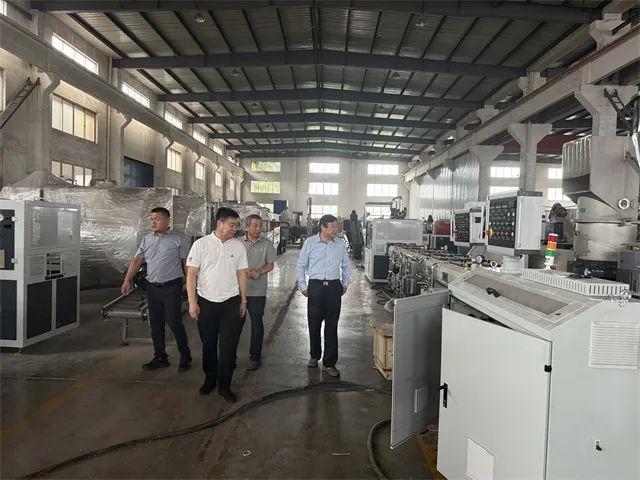

At Zhangjiagang Yatong Machinery Co., Ltd., General Manager Huang Wei welcomed President Duan and his delegation, and led them on a tour of the company's production workshop and product showroom. In the company office, President Duan had an engaging conversation with General Manager Huang and Huang Shiming, a well-known figure in the Zhangjiagang plastic machinery industry. The Zhangjiagang plastic machinery industry has been a major partner for President Duan since his time working in enterprises and after starting his own business, providing significant support for the development of his career.

Chairman Duan and the two others are also longtime old friends who have had very close interactions over the years. When recalling the past and talking about the present, they feel deeply moved and have endless stories to share about their lifelong dedication and journey in the industry.

Zhangjiagang Yatong Machinery Co., Ltd.It is one of the leading and key enterprises as well as professional manufacturers of plastic machinery in China. The company has one subsidiary, specializing in the production of various specifications of projection screens, with products exported both domestically and internationally. The company is located in Sanxing Economic Development Zone, Baojiagang City (5 kilometers from County Road 202, at the original 864-kilometer mark of National Highway 204), covering an area of 18,000 square meters, with a factory area of 15,000 square meters. The company specializes in the production of various types of single-screw extruders, conical twin-screw extruders, high-speed cooling mixers, various plastic pipe and profile extrusion production lines, various plastic sheet and board extrusion production lines, PVC, PP, PE, XPS, EPS foam extrusion production lines, wood-plastic co-extrusion foam production lines, PE, PP, PET washing production lines, and other related auxiliary equipment. With outstanding performance and prompt, attentive service, our products are exported to Russia, India, Turkey, the Middle East, Central Asia, Southeast Asia, Africa, and Europe, receiving widespread acclaim.

Standing at the starting line of the new century, Yatong people will continue to uphold the corporate creed of "leading the trend and providing attentive service." The company's business philosophy is "to use advanced scientific technology and reasonable manufacturing processes to provide customers with the highest quality machinery equipment."

Arriving at Jiangsu Beier Machinery Co., Ltd., Chairman He Defang, who is also the Supervisor of the Zhangjiagang Plastic Beverage Machinery Association, and Mr. Jiang Weibing, Sales Director of Xingbeier, warmly received President Duan and his delegation. Chairman He... Minister Jiang led Chairman Duan on a tour of the company's production workshop and introduced the current main product production, market operations, and future development plans of the company. Chairman Duan and President He have been long-time friends and have maintained a good cooperative relationship. Chairman Duan has witnessed the development and growth of Bell and expressed admiration for President He's spirit of hard work and entrepreneurship in the industry over the years. Bell has maintained deep cooperation with many plastic industry companies in Henan, particularly in recent years, playing an important role in the fields of pipe extrusion and plastic product recycling.

Jiangsu Bell Machinery Co., Ltd. is located in the conveniently accessible Zhangjiagang National Economic and Technological Development Zone in Jiangsu Province. It is a national high-tech enterprise, a national specialized and new "little giant" enterprise, and a vice president unit of the China Plastics Machinery Industry Association. The company has a modern standard factory building of 38,000 square meters and a modern research building of 6,000 square meters. In 2022, the company invested in the establishment of "Bell Intelligent Equipment (Nantong) Co., Ltd." in Nantong, constructing a new standardized factory and research office building of 55,000 square meters.

Since its establishment in 1998, Bell has been serving customers in more than 130 countries and regions worldwide with efficient and energy-saving European-style production lines for PE/PP/PPR/PVC pipes, sheets, and profiles, as well as PVC compounding, quantitative feeding systems, and plastic waste recycling production lines. By providing stable and sustainable operational benefits, Bell has created value for over 600 plastic enterprises and formed partnerships to jointly promote the development of a circular economy across various industries including public infrastructure construction, the building market, and plastic recycling.

Innovation is one of Bell’s core values. It guides Bell to continuously evolve and grow, accumulating reputation through further technological upgrades, product and service improvements, customer satisfaction, and giving back to society. Most importantly, it serves to fulfill our brand mission: "Innovate for sustainability, take pride in customer success." We believe that "true action brings real power." Bell always considers how to make production more efficient and environmentally friendly, thereby forming a core competitive advantage for sustainable development. Let us work hand in hand to contribute to the low-carbon development of the global new plastics industry, and to the cause of global energy conservation, emission reduction, and green economic growth!

At Jiangsu Vida Machinery Co., Ltd., Sales Director Xiang Kui and Plastic Machinery Technology Department Manager Li Bin led President Duan and his delegation to visit the company's production workshop. During a meeting in the conference room, Director Xiang introduced President Duan to the company's development history, main products, core business, scientific and technological innovations, and market expansion. President Duan recalled the scene of jointly developing a new product market with Chairman Gao of Vida in the past. He mentioned, "I have always been attentive to Vida's development and with Gao..." They have also maintained a friendship for decades. The first customer of Vinda's new product back then was a company from Henan. We hope that Vinda will continue to closely cooperate with plastic processing enterprises in Henan to jointly promote the high-quality development of the industry.

Jiangsu Vinda Machinery Co., Ltd., founded in 1958, is a technology-driven innovative enterprise integrating research and development, production, and sales, dedicated to providing high-quality customized plastic machinery solutions for global customers. The company is located in the High-tech Zone of Zhangjiagang City, Jiangsu Province, with convenient transportation, and its products are sold in more than 50 countries and regions worldwide.

The company's main products include injection-blow molding machines, precision molds, extrusion calendering production lines, etc. These products are widely used in industries such as medical health, food and daily chemical packaging, environmental filtration, and 5G communication, occupying a leading market position in various segments. As a national-level specialized and innovative "Little Giant" enterprise and a high-tech enterprise, Vida Machinery is the main drafting unit for several national and industry standards for injection-blow molding machines.

The company focuses on technological innovation and R&D investment, dedicating itself to creating green, safe, and intelligent equipment centered on high efficiency and energy saving. By leveraging cloud platforms and IoT technologies, it meets customers’ digital service needs. The company is equipped with advanced precision machining equipment and automated flexible production lines, and through the development of a 5G digital factory, it achieves transparent management of the entire order process.

Vinda Machinery consistently uses technological innovation as a driving force, continually exploring the depth and breadth of intelligent manufacturing and digital transformation. Upholding the business philosophy of ensuring customer satisfaction and employee happiness, it collaborates with global partners to shape a more efficient and sustainable industrial future.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track