Hardcore Debut of Olefins: Supporting Extreme Aerospace Environments

Among the many materials supporting the stable operation of high-end equipment, olefins, with their unique chemical properties, are transformed into materials possessing characteristics such as "lightweight, high-temperature resistance, radiation resistance, and high energy density" through technologies like polymerization, modification, and compounding. These materials permeate the aerospace field, from structural components to fuel and from basic parts to functional protection in all scenarios, becoming a crucial chemical force supporting extreme environments in aerospace.

01

Polyolefin family

Top 5 Members Overview

When it comes to "olefins," many people may find the term unfamiliar. Olefins are a class of small-molecule organic compounds containing carbon-carbon double bonds. They are often used as raw materials and can undergo polymerization reactions to produce long-chain polymers such as polyethylene and polypropylene, which are then processed into synthetic fibers. These have wide applications in both daily life and industrial fields.

From the strict definition in organic chemistry, "hydrocarbons" specifically refer to organic compounds composed only of carbon and hydrogen elements, and alkenes are an important branch of hydrocarbons. Their core structural feature is the presence of a carbon-carbon double bond (C=C) in the molecule. The existence of this unsaturated bond makes their chemical properties more reactive, and thus they are classified as unsaturated hydrocarbons.

It is worth noting that olefins can form a vast "polyolefin family" through polymerization reactions.

These types of olefin derivatives are currently crucial in the aerospace field. By specifically modifying different kinds of polyolefins, they can be precisely tailored to meet the functional requirements of various basic components of spacecraft, such as withstanding extreme temperature variations and resisting cosmic radiation. In this way, they provide a vital first line of defense for the safe and stable operation of aerospace equipment in the complex and harsh environment of outer space.

Next, we will explore the specific application scenarios of the five core members of the polyolefin family in the aerospace field.

01

Polyethylene (PE)

Polyethylene, with its excellent low-temperature resistance and chemical corrosion resistance, has become the core choice for fluid transmission and insulation protection.

In the fuel and hydraulic pipelines of spacecraft and aircraft, PE liners can effectively isolate fuel and hydraulic oil from direct contact with metal pipes, thus preventing metal corrosion and the resulting risk of leakage. The PE insulation layer on the outer sheath of satellite cables, due to its low volatility, can prevent material outgassing from contaminating satellite optical instruments, thereby ensuring detection accuracy. Furthermore, in cryogenic fuel tanks for liquid oxygen and liquid hydrogen, PE sealing gaskets can remain flexible even at extremely low temperatures, completely solving the problem of brittle fracture found in traditional materials under such conditions.

02

Polypropylene (PP)

As a lightweight and high-strength polymer material, polypropylene has demonstrated remarkable achievements in aerospace engineering. Its application value becomes even more prominent, especially after environmentally friendly modification.

With the combined advantages of "lightweight + high strength," it reshapes aerospace interiors and non-load-bearing structures. After adopting PP composite materials for interior components such as aircraft seat frames, instrument panel shells, and luggage racks, the weight is reduced by more than half compared to traditional metal components.

According to publicly available information online, in China's C919 aircraft, polypropylene is used for seat frames, dashboards, and other interior parts, reducing the weight of a single aircraft by about 120 kg. For the AG600, replacing the original steel alloy hatch (weighing 237 kg) with polypropylene plastic reduces the weight of a single hatch by about 180 kg.

In the instrument cabin of a spacecraft, partitions and protective covers made of PP can not only bear the weight load of instrument equipment, but also reduce the overall launch mass of the spacecraft, thereby freeing up space to accommodate more scientific payloads.

03

Polyolefin Elastomer (POE)

With its high elasticity and weather resistance, polyolefin elastomer has become an indispensable material in the fields of sealing and vibration damping.

The POE sealing strips used on aircraft cabin doors and windows can maintain excellent sealing performance under high-altitude low pressure and drastic temperature changes, preventing external cold air and moisture from penetrating, thereby ensuring a comfortable cabin environment. The POE cushioning pads on spacecraft instrument mounts can effectively absorb the intense vibrations during rocket launch and the impact energy during landing, protecting precision instruments from damage caused by shocks.

04

Cross-linked polyethylene (XLPE)

Cross-linked polyethylene enhances high-temperature and radiation resistance through crosslinking modification, becoming a "reliable choice" for high-temperature and radiation environments.

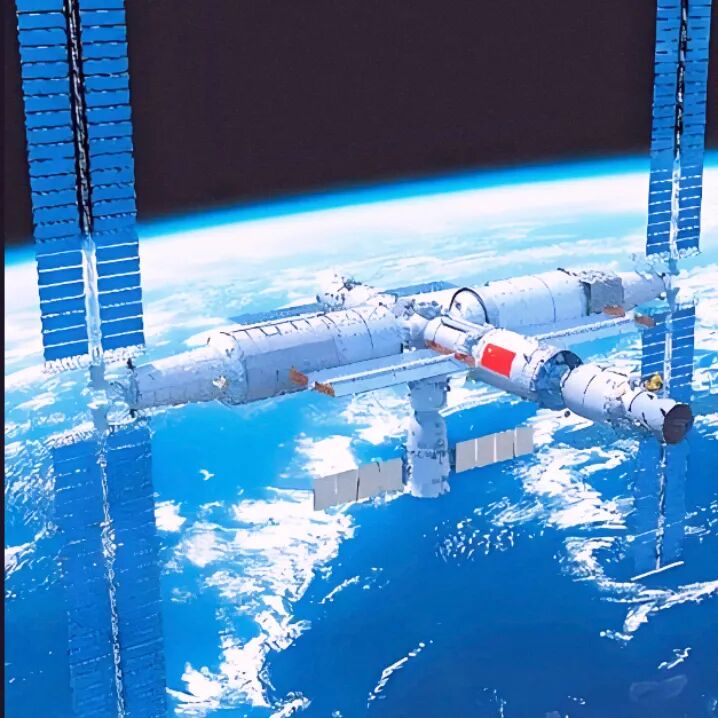

The high-temperature lubrication oil pipelines around aircraft engines, when using XLPE material, can withstand temperatures of approximately 95℃ over the long term, ensuring stable transmission of the lubrication oil. The XLPE interior panels in the living module of a space station can not only resist space gamma rays and proton radiation but also reduce the release of harmful gases, creating a safe and healthy living environment for astronauts.

05

Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene is the ultimate protector in extremely corrosive environments.

Piston rings and valve seals in aircraft hydraulic systems are subjected to high pressure and hydraulic oil corrosion for extended periods. PTFE material can maintain stable performance under these conditions, preventing hydraulic system leakage. In the nozzles lining of spacecraft propulsion systems, when in contact with chemically reactive substances like hydrazine fuels, the corrosion resistance of PTFE ensures that the nozzles are not eroded, thereby ensuring stable propellant ejection.

02

From Aviation Kerosene to Rocket Fuel Breakthrough

Alkene derivatives

Aerospace fuels not only need to meet the core requirements of high energy density and stable combustion but also must adapt to special environments such as low temperatures at high altitudes and low atmospheric pressure in space. Derivatives formed through the catalytic conversion of olefins provide a key pathway to address fuel resource dependency and adaptation to extreme environments.

In the field of aviation kerosene, olefins are key intermediates for replacing fossil fuels. Traditional aviation kerosenes (such as JET-A and RP-3) rely heavily on petroleum refining, whereas through the "Fischer-Tropsch synthesis" technology, olefins can be converted from non-petroleum resources such as coal and natural gas: first, coal or natural gas is converted into synthesis gas, then into olefins, and finally into highly branched alkanes through hydroisomerization.

These highly branched alkanes can lower the freezing point of aviation kerosene to very low levels, adapting to the low-temperature environment at high altitudes, while also burning more completely, reducing engine carbon deposits, and improving fuel efficiency.

Nowadays, the technological route from coal-to-olefins to aviation kerosene has become increasingly mature, effectively easing the dependence of aviation fuel on petroleum resources and providing a new direction for the sustainable development of the aviation industry.

In the field of rocket fuels, olefin derivatives are enhancers that improve fuel performance.

The combination of olefins with hydrazine-based fuels can significantly increase the energy density of the fuel, resulting in higher rocket specific impulse and greater payload capacity. Polymer fuels formed by the polymerization of olefins, such as polyethylene-based fuels, feature high density and low volatility. In the low-pressure environment of space, they can effectively reduce fuel evaporation loss, making them especially suitable for use in small solid rocket engines. This provides stable power support for missions such as microsatellite launches and deep space exploration.

03

New Path for Aerospace Weight Reduction

Polyolefin-based composites

Weight reduction is a perpetual pursuit in the aerospace industry. For commercial aircraft, reducing weight by 1 kilogram can save $60,000 in fuel costs annually. For spacecraft, the economic benefit of reducing weight by 1 kilogram is nearly $100,000. For rockets, reducing weight by 1 kilogram can save approximately $20,000 in launch costs.

Polyolefin-based composites, formed by compounding olefins with fibers, have become a driving force in replacing traditional metal materials due to their "lighter and stronger" characteristics, ushering in a revolution in lightweight technology.

Carbon fiber reinforced polypropylene (CF/PP) composites are regarded as a perfect combination of lightweight and high strength. Their density typically ranges between 1.1 and 1.4 g/cm³, which is more than 50% lighter than metal materials. The tensile strength can reach 50-100 MPa, which is 2-3 times higher than that of pure PP.

In aircraft manufacturing, CF/PP composites are widely used in secondary load-bearing structures such as wing leading edges and tail skins, which not only reduce the weight of the wings but also enhance their resistance to aerodynamic impact. In the field of aerospace, satellite brackets made from CF/PP composites can significantly reduce the overall weight of satellites while ensuring structural stability, enabling satellites to carry more scientific instruments.

Glass fiber reinforced polyethylene (GF/PE) composites, with their high cost performance and excellent impact resistance, have filled the gap in mid- to low-end application scenarios.

The GF/PE protective panels of the aircraft landing gear compartment can withstand the impact of stones and dust during takeoff and landing, protecting the key components of the landing gear. The landing cushioning structure of spacecraft uses GF/PE composite material, which can absorb the enormous kinetic energy during landing through material deformation, reducing the impact damage on the main body of the spacecraft. This is particularly suitable for planetary landing missions such as Mars probes and lunar rovers.

04

Facing strong radiation, high temperature, and static electricity

Functional Olefin Materials

Aerospace equipment faces a wide variety of extreme and complex environments—such as intense radiation in space, ozone corrosion at high altitudes, and high-temperature erosion from engines—all of which place special functional demands on materials.

Functional materials formed by specially modifying olefins have become specialized weapons to resist these extreme challenges.

Radiation-resistant olefin materials are enhanced by adding rare earth oxides and other anti-radiation agents, or by crosslinking modification to improve molecular chain stability, thus creating a "radiation protection suit" for spacecraft.

The radiation-resistant olefin insulation layer of spacecraft cables can effectively withstand erosion from space gamma rays and proton radiation, preventing insulation aging and damage that could lead to short-circuit failures. In nuclear-powered spacecraft, protective shells made of radiation-resistant olefin can block radiation leakage from nuclear reactors, ensuring the safety of onboard equipment and astronauts.

Antistatic polyolefin materials solve the electrostatic safety hazards in the aerospace field by incorporating conductive fillers such as carbon black and graphene.

After the inner walls of the aircraft fuel tank are made of antistatic olefin material, the static electricity generated by the flow of fuel can be promptly discharged, preventing the risk of explosion caused by static accumulation. The antistatic olefin material used in the frames of spacecraft solar panels can quickly release static electricity generated on the panel surface due to cosmic ray exposure, avoiding static interference with the power generation efficiency of the solar panels.

High-temperature wear-resistant olefin materials achieve dual resistance to high temperature and abrasion through the incorporation of ceramic particles such as alumina and silicon carbide.

The high-temperature wear-resistant olefin coating for aircraft engine blades can withstand the scouring of high-temperature airflow above 1000°C inside the engine, reducing blade wear and extending engine service life. When spacecraft re-enter the atmosphere, high-temperature surface areas rely on ceramic and other ablation materials for protection, while high-temperature wear-resistant olefin materials can be used as the non-directly heated lining of the thermal protection layer to help dissipate heat, ensuring the safe return of the spacecraft to the ground.

05

Material foundation, widely applied.

The future is promising.

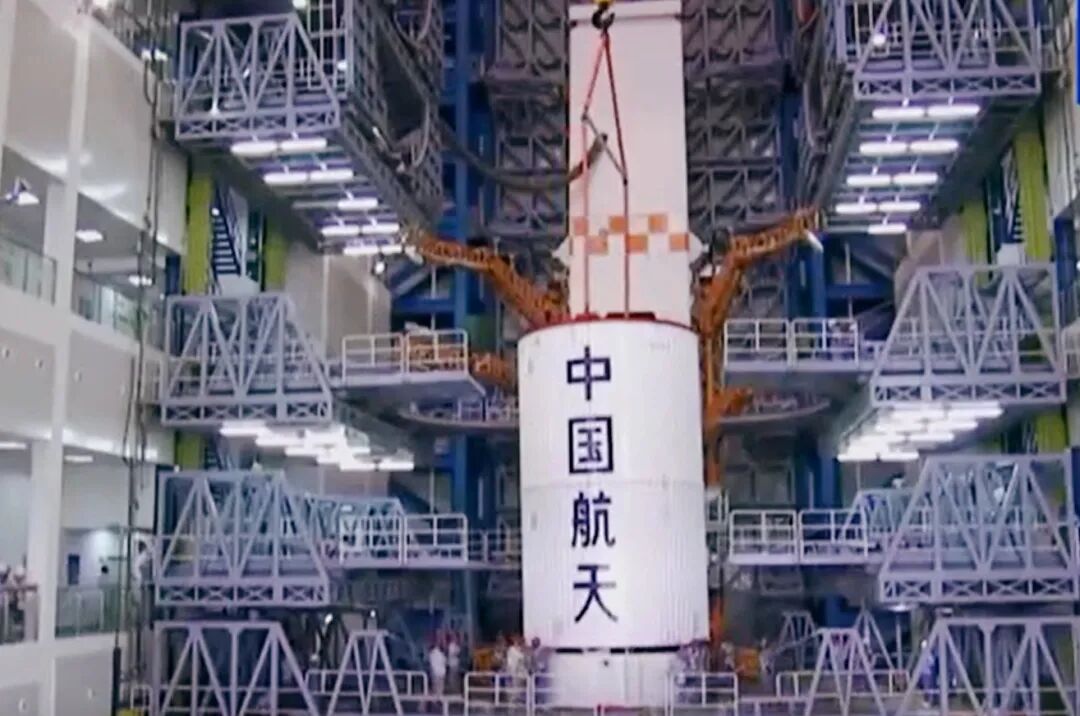

Olefins are fundamental raw materials in the materials industry. The level of a country's olefin industry—including production capacity, technological strength, and self-sufficiency in high-end products—largely represents the overall competitiveness of its petrochemical sector.

Taking the most widely used polyethylene as an example, it was first synthesized by the British company ICI in 1933 and achieved industrial production in the United States in 1939. However, it was not until 1976 that China built and commissioned its first polyethylene plant in Shanghai Petrochemical.

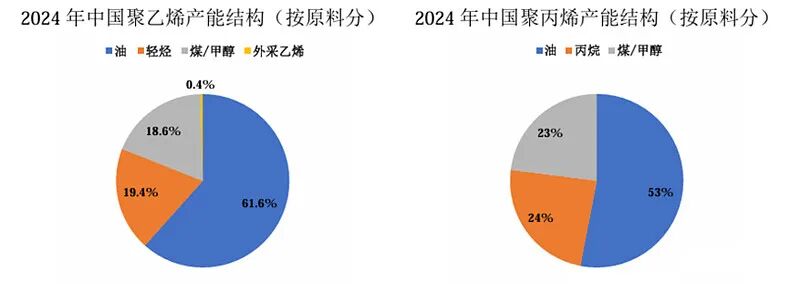

After decades of development, by 2024, China's polyethylene production capacity has exceeded 34 million tons, accounting for 21% of the global total capacity.

In terms of annual new capacity, the global polyethylene in 2024 will be 5.16 million tons, of which China will add 3.4 million tons, accounting for as much as 66%. China has become the main driving force behind the growth of global polyethylene capacity.

From basic components to core fuel, from structural support to functional protection, olefins, with their "one material, multiple functions" characteristic, are deeply integrated into every key aspect of the aerospace industry.

As aerospace technology advances toward deeper space, higher efficiency, and more extreme environments, the performance requirements for olefin materials will continue to upgrade. Meanwhile, technological innovation in the olefin industry will constantly provide new possibilities for aerospace equipment to break through limits, continuously supporting the coordinated development of chemical materials and high-end equipment.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track