Groundbreaking Nature Study: 3D-Printed Porous Scaffolds Provide Robust Insulating Mycelium-Based Composites for Green Building

Pain points in the construction industry: The construction sector accounts for 37% of global greenhouse gas emissions. Traditional brick production emits 0.8-1.2 kg of CO₂ per brick. Insulation materials (such as mineral wool and EPS) have significant environmental impacts throughout their life cycles. By 2050, related carbon emissions may increase by 50%, whereas sustainable practices can reduce emissions by 40%.

Limitations of bio-based materials: Although bio-based materials (such as bamboo and mycelium) are low-carbon and carbon-sequestering, they have issues such as unstable quality, sensitivity to moisture, flammability, and poor durability.

Traditional MBCs have shortcomings: Mycelium-based composites (MBCs) are sustainable biomaterials, but their yield strength is only 0.01-0.72 MPa, and the growth of mycelium is uneven, making it difficult to meet construction requirements.

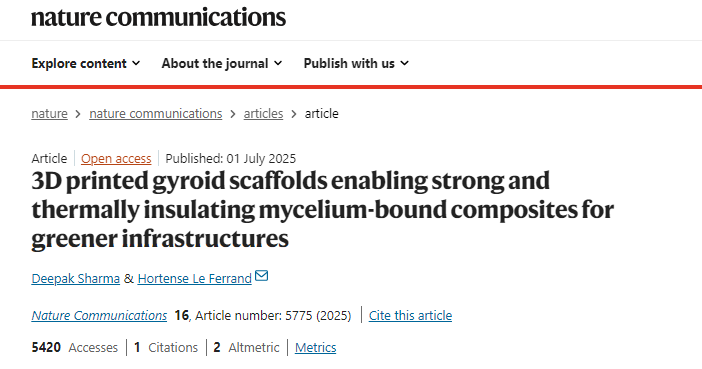

By 3D printing wooden-polylactic acid (PLA) porous spiral scaffolds, we address the issues of low mechanical strength and uneven mycelium growth in traditional MBCs, while enhancing their thermal insulation, fire resistance, hydrophobicity, and durability, ultimately developing sustainable composite materials to replace environmentally harmful building materials.

(a) Core Materials and Preparation

3D printed scaffolds: Print a gyroid structure (TPMS) using recycled filament made of 40% wood + 60% PLA, as it optimizes surface area and strength.

Mycelium Cultivation: Select Ganoderma lucidum strains and use a 10% w/v malt PMA solution (peptone + malt + agar) as a nutrient source. Incubate for 21 days at 23°C and 80% humidity. Samples are divided into "inactive" (growth terminated by drying at 48°C) and "active" (mycelium remains viable) groups.

Key Testing Methods

Covers mechanics (compression, shear), thermal insulation (thermal conductivity, infrared imaging), fire resistance (burn area/weight change), hydrophobicity (contact angle, water absorption test), durability (300 days environmental exposure), and chemical analysis (XPS, FTIR).

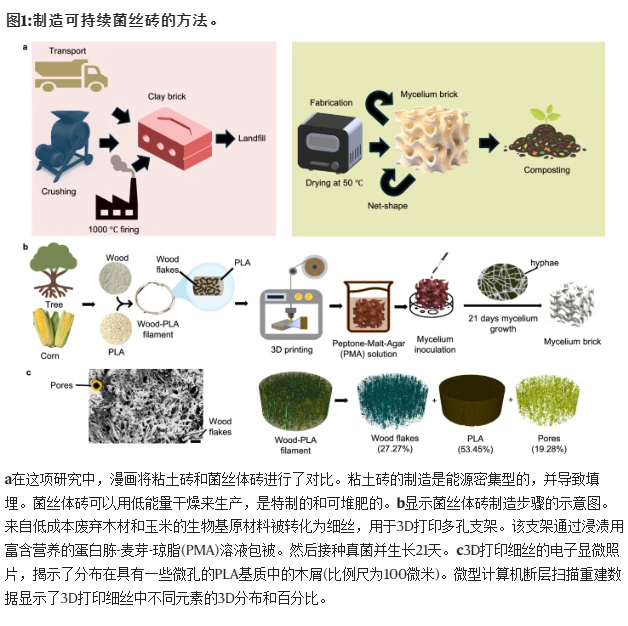

Optimization of Mycelium Growth

Malt concentration: 10 w/v% Malt balances the mycelium's "exploration" and "utilization" behaviors, covering 70% of the pore space of the scaffold in 14 days and forming a dense layer in 21 days.

Support pore rate: 90% - The high porosity allows for good air circulation (sufficient oxygen and easy CO₂ discharge), resulting in the highest mycelial density; 50% - The low porosity leads to stagnant air, resulting in sparse mycelium.

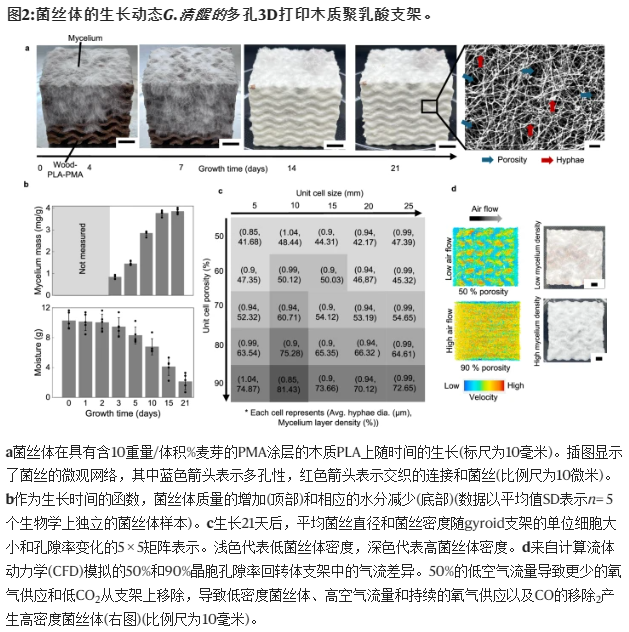

(2) Improvement of Material Performance

Mechanical properties: MBCs with 50% porosity exhibit a yield strength of 7.29±0.65 MPa (far exceeding the traditional MBCs' 0.01–0.72 MPa); for samples with 90% porosity, the yield strength increases by 77.7%, and the specific energy absorption increases by 133.3%.

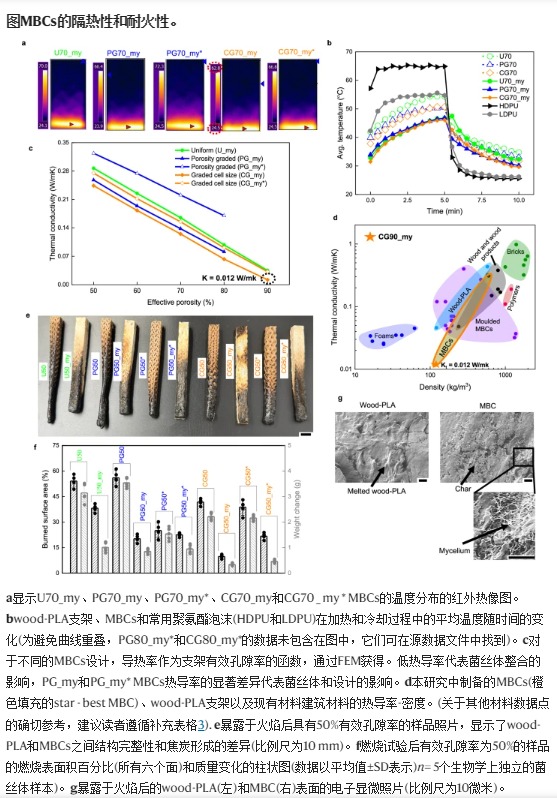

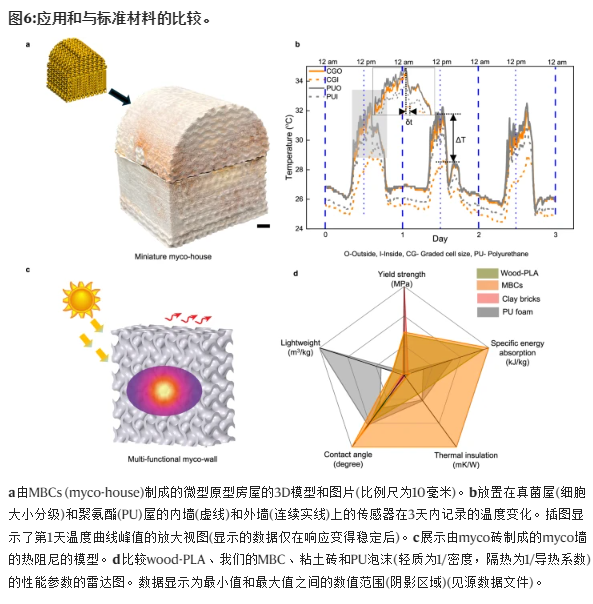

Thermal insulation performance: 90% porosity MBCs have a thermal conductivity as low as 0.012W/mK, superior to traditional PU foam; gradient design (such as cell size gradient) further optimizes insulation, with a temperature difference twice that of PU houses.

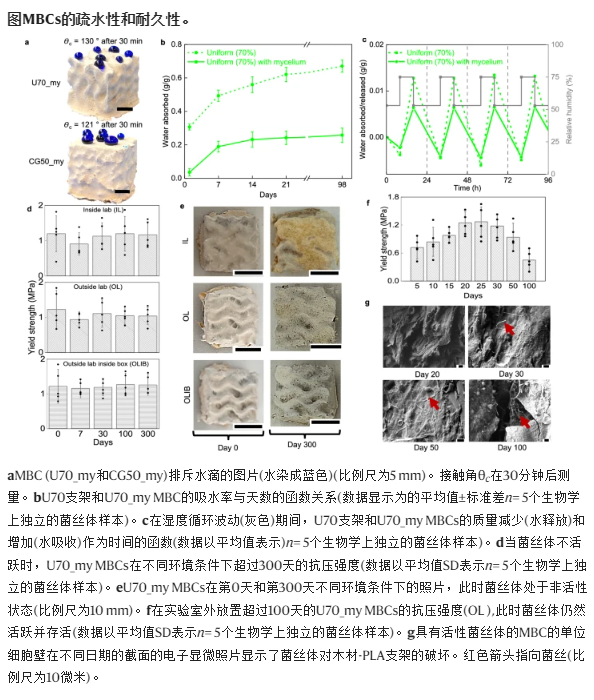

Fire resistance and hydrophobicity: MBCs inhibit fire through char formation, with the sample having a 50% porosity gradient exhibiting the smallest combustion area; the mycelium increases the contact angle from 85.5° to 130.9°, and reduces the water absorption rate by 2.6 times.

Durability: Non-active MBCs (dried mycelium) were placed in three environments for 300 days, with no significant changes in mechanical properties; active MBCs experienced a strength reduction of 2.82 times due to the degradation of the scaffold by the mycelium over 100 days.

Technical breakthrough: The synergy of 3D-printed helical scaffolds and mycelium enables MBCs to possess both brick-level strength and foam-level thermal insulation, resolving the "strength-function" contradiction of bio-based materials.

Application value: It can replace clay bricks and PU foam, and be used for false walls, insulation panels, etc. A miniature "mycelium house" has verified its insulation advantages, providing a new path for carbon reduction in construction.

Limitations: Performance improvement is most significant at high porosity (90%), requiring further optimization of the "porosity-performance" balance; production cycle is longer than traditional materials, but the embodied energy is lower.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track