Golden Hair Technology's Stock Price Soars 153% This Year, Begins Mass Supply to Humanoid Robot Clients

The company's stock price has surged 153% this year by jumping on the "embodied robot" bandwagon! What are the hard strengths behind it?

Since the beginning of this year, the concept of "embodied robots" in the A-share market has continued to be a hot topic, with companies in related industrial chains frequently attracting attention from investors. Among them, Kingfa Sci & Tech Co., Ltd. (600143), a leading company in the materials sector, has garnered significant interest with its lightweight materials for robots, PEEK, liquid cooling technology, and other popular concepts. Its stock price has risen by more than 153% this year, showing remarkable performance.

At the semi-annual performance briefing on September 19, 2025, Wu Di, the director and general manager of Jinfa Technology, stated, "Currently, the company has engaged in collaborative research and development of materials related to embodied intelligent robots with several leading enterprises in the humanoid robot field, and some customers have entered the mass supply stage." In addition, Jinfa Technology is also advancing deep joint development projects with several potential customers, and the results are expected to gradually materialize in the future.

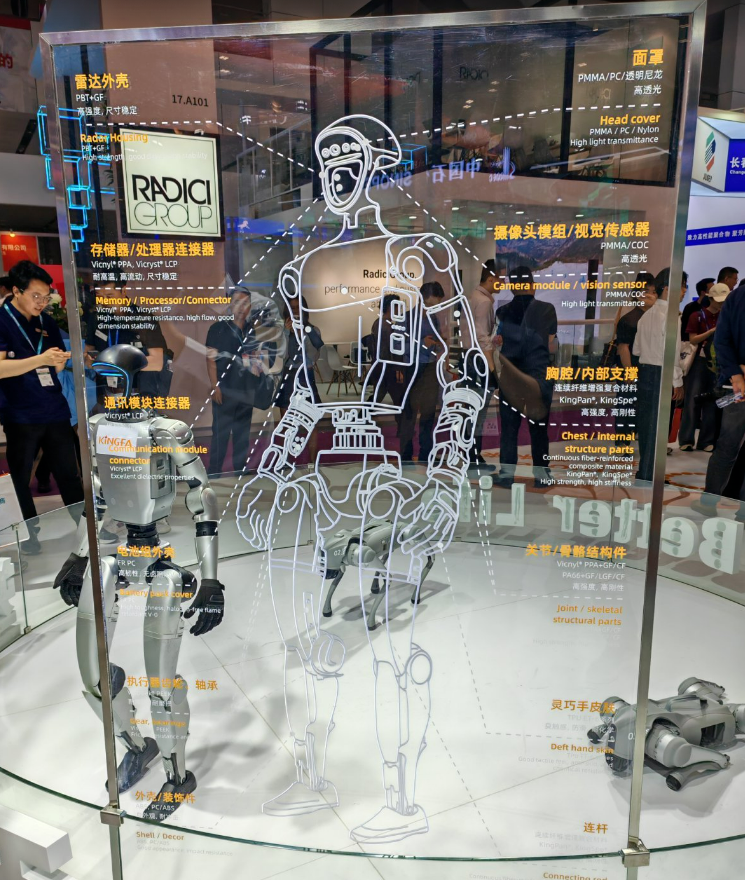

In the field of humanoid robots, Jinfatech has established a dedicated research and development team for robot materials, which will continue to advance material technology and customer project integration, in order to be fully prepared for the industry's explosive growth period.

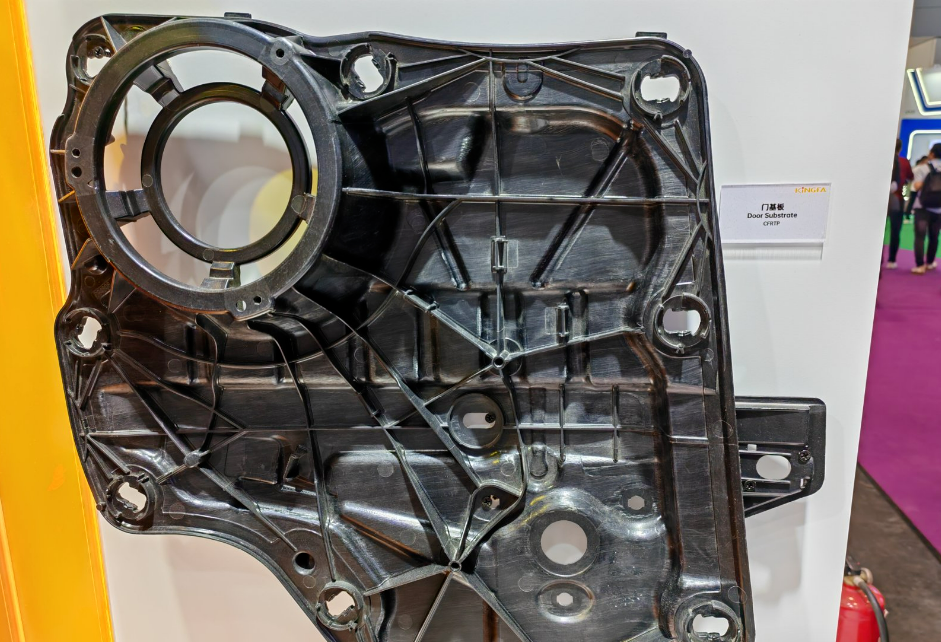

Golden Hair Technology was founded in 1993 and is one of the companies with the most comprehensive range of products in the global chemical new materials industry. Its products include modified plastics, environmentally friendly high-performance recycled plastics, biodegradable plastics, specialty engineering plastics, carbon fibers, and composite materials, among nine major categories. Its downstream applications span various industries such as automotive, home appliances, electronics and electrical engineering, consumer electronics, new energy, high-end equipment, and healthcare.

Jinfa Technology stated that the rapid development of strategic emerging industries such as smart cars, new energy, artificial intelligence, humanoid robots, low-altitude economy, VR/AR, 5G communications, and new infrastructure has provided strong market demand for the company. In the first half of 2025, the company achieved revenue of 31.636 billion yuan, a year-on-year increase of 35.5%; net profit was 585.3 million yuan, a year-on-year increase of 54.12%.

In the field of specialty engineering plastics, Kingfa Technology has developed production capabilities for PEEK, LCP, and PPA. On the downstream application side, Kingfa Technology's halogen-free flame-retardant semi-aromatic polyamide with electronic fluorination resistance is widely used in immersion-cooled server storage connectors, supporting high-speed transmission of 12800MT/s. The new generation of low dielectric LCP materials has been mass-produced for high-speed connectors in AI servers, achieving a transmission rate of 224Gbps. Ultra-temperature-resistant, fatigue-resistant, and wear-resistant PPA materials have successfully addressed the long-life requirements of key components in robotics, achieving industry applications. PEEK materials, with their properties of being lightweight, high-temperature resistant, self-lubricating, and corrosion-resistant, have become an important choice for replacing steel in humanoid robot joints and skeletons.

With the increasing demand for domestic alternatives, Kingfa Sci & Tech's performance in the high-end new materials market is expected to accelerate. Currently, the company's total production capacity for specialty engineering plastics is nearly 34,000 tons per year, with several capacity expansion projects actively advancing: the initial 5,000 tons per year LCP resin facility is about to start production; a 40,000 tons per year specialty polyamide project has been initiated; a kilo-ton level polyimide project is planned to start production by the end of 2025; and a 50,000 tons per year blending modification factory has entered the construction phase.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track