Golden hair technology launches 40,000-ton bio-based high-temperature nylon project: An Overview of Domestic and International Bio-Based Nylon Enterprises and Product Layouts

On August 6, Zhuhai Wantong Special Engineering Plastics Co., Ltd. announced the environmental impact assessment information for its project to produce 40,000 tons of bio-based high-temperature nylon annually (Phase I). This marks another significant step in Kingfa Sci. & Tech. Co., Ltd.'s (600143.SH) strategic layout in the high-end nylon sector.

As an important subsidiary of Kingfa Sci. & Tech. Co., Ltd., Zhuhai Wantong has launched a Phase I project with a production capacity of 8,000 tons per year. The main products include bio-based high-temperature nylon PA10T/1012, PA1012, PAMACM12, and other specialty materials. The project is located in the Petrochemical Base of Nanshui Town, Jinwan District, Zhuhai City, covering a total area of nearly 20,000 square meters. This investment not only strengthens Kingfa Sci. & Tech.'s leading position in the field of bio-based high-end materials but also reflects the positive trend of China's specialty nylon industry in the global green transformation of chemical materials.

1. Golden Hair Technology 2025Year Strategic Layout Panorama

As a leading enterprise in modified plastics in China, Kingfa Sci & Tech demonstrates strong momentum in technological innovation and industrial upgrading in 2025.

Production capacity layoutIn terms of strategic adjustments, Kingfa Sci & Tech Co., Ltd. in 2025 exhibits a "mixed increase and decrease" approach. The increased production capacity is primarily focused on high-end sectors: besides the 8,000-ton/year bio-based high-temperature nylon phase-one project initiated by Zhuhai Wantong, the company has gradually commenced production of a 15,000-ton/year LCP (liquid crystal polymer) polymerization facility at its Guangzhou headquarters base since June. Simultaneously, company announcements indicate that the Chengdu Kingfa phase-one project has established a production capacity of 200,000 tons per year with an annual output value of 3 billion yuan. The phase-two project has also been initiated, with plans to commence production by the end of the year.

Technological InnovationBecome the core driving force for the development of Jinfake Technology in 2025.The first half of the year.Golden Hair Technology and Zhuhai Wantong jointly applied for three major patents, covering multiple directions such as polypropylene/liquid crystal polyester alloy, high-temperature low dielectric loss liquid crystal polymer composites, and liquid crystal polyester compositions. They independently applied for a patent related to the polyamide/polyphenylene ether resin composite system. Among them, on June 28, the "PolypropyleneLiquid crystal polyester alloyThe patent (CN120209449A) is particularly noteworthy. This technology uses homopolymer polypropylene as the main component and exploits the incompatibility between LCP and PP to form a heterogeneous two-phase network. This allows the material to have a high dielectric constant response under the influence of an electric field while maintaining insulating properties, providing a new material solution for 5G communication devices. This was disclosed on July 25th.High-temperature low dielectric loss liquid crystal polymer compositesThe patent (CN120365760A) achieves a dielectric loss of no more than 0.008 under high-frequency conditions of 10GHz and high temperatures of 150°C by adding polytetrafluoroethylene and wollastonite in specific proportions, while maintaining a flexural strength of over 60MPa. This perfectly meets the high-performance material requirements for 6G communication devices.

High-performance developmentIn 2025, Kingfa Sci. & Tech. Co., Ltd. achieved groundbreaking progress. According to the company's official website, its independently developed bio-based high-temperature nylon PA10T series products, with their extremely low water absorption, ultra-high heat resistance, and good dimensional stability, have been mass-applied in 5G base station antenna covers and new energy vehicle battery modules. In the AI and consumer electronics fields, Kingfa Sci. & Tech.'s PA10T market share in DDR5 connectors even exceeds...

Moreover, it is noteworthy that Golden Hair Technology has achieved mass production capability for LCP film-specific resin, and its low dielectric loss LCP material has passed small-scale validation by end manufacturers.

PA10T can be used as an LDS material for mobile phone stand antennas, mobile phone speaker stands, internal stands for smart watches, LDS antenna materials, etc. Image source: Kingfa Technology.

The future prospects for bio-based nylon are promising.

In the current context of a "low-carbon economy," bio-based nylon materials demonstrate broad development prospects. In 2023, the global bio-based nylon resin market size reached $421.7 million and is expected to increase to $678.3 million by 2028, with a compound annual growth rate (CAGR) of 9.4% during the forecast period (2023-2028). This accelerated growth is driven by the tightening of global environmental regulations and the surging demand for sustainable materials in the automotive, electronics, and textile industries.

Bio-based nylon materials are polymer materials obtained by using renewable biomass raw materials (such as glucose, cellulose, plant oils, etc.) to prepare nylon monomers through biological, chemical, and physical methods, followed by polymerization reactions.

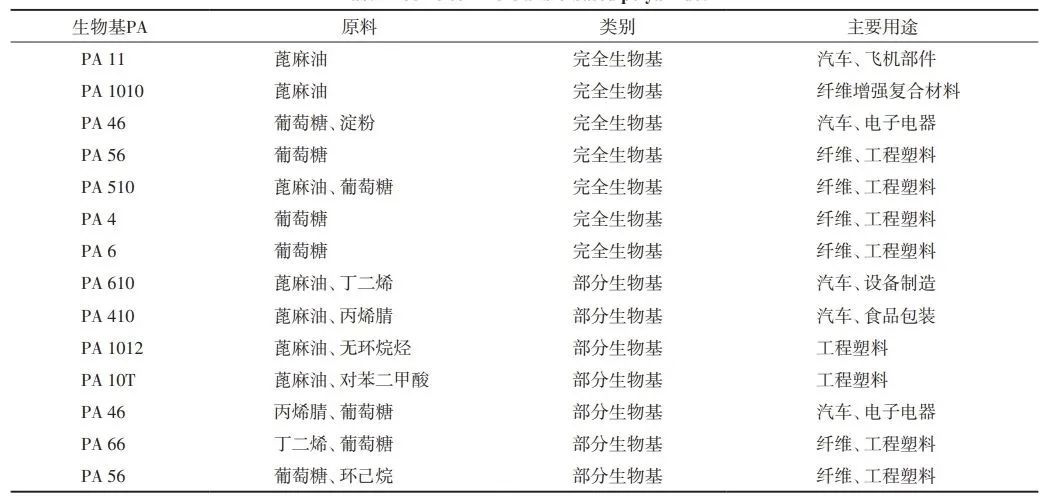

The currently commercialized bio-based nylons mainly include PA11, PA1010, PA610, PA1012, PA56, PA510, among others, with more products continuously under development. The production technology is mainly divided into two pathways.

- Sugar route: Using glucose, cellulose, starch, etc. as raw materials, core monomers such as γ-aminobutyric acid, caprolactam, adipic acid, and pentamethylenediamine are produced through microbial fermentation. For example, bio-based nylon 56 is made by fermenting glucose to produce the 1,5-pentanediamine monomer.

- Oil route: Using vegetable oils such as castor oil, oleic acid, and linoleic acid as raw materials, monomers such as ω-undecenoic acid, sebacic acid, and azelaic acid are prepared through chemical conversion processes like transesterification and high-temperature cracking. For example, bio-based nylon 1010 is made using castor oil as a raw material to produce the sebacic acid monomer.

Partially commercialized bio-based nylon (Source: China Chemical Information Weekly)

3. Review of Biobased Nylon Enterprises and Product Layout

As the industrial sector prioritizes the circular economy model, leading chemical manufacturers are commercializing bio-nylon solutions that maintain high performance while significantly reducing the carbon footprint. Here, we list some representative companies in the bio-based nylon industry and their product layouts for your reference.

Arkema

Focusing on castor oil as the core raw material, the main products are PA11, PA1010, and PA610. Castor oil is converted into monomers (such as ω-aminoundecanoic acid) through a transesterification-high temperature cracking-ammonolysis process. Starting from 2025, the carbon footprint of its PA11 will be reduced to 1.3 kg CO₂e/kg, with a target of reaching 1 kg CO₂e/kg by 2030.

Focusing on the castor oil route, producing PA1010, PA610, and PA1012. The technical core involves the cracking of castor oil to produce sebacic acid, which is then polycondensed with different diamines. In 2024, it will integrate biomass balance ammonia (ISCC PLUS certification) for the production of PA12.

BASF

Using castor oil as a raw material, focus on developing PA610 and PA11. In 2025, the world's first recycled polyamide 6 (loopamid®) facility will be commissioned, with an annual capacity of 500 tons (GRS certified). In 2024, the bio-based Ultramid® series will be launched, utilizing bio-methane as a raw material.

Producing PA1010 and PA610, represented by the Zytel® RS series, used for automotive fuel lines as a replacement for petroleum-based PA11/PA12.

Cathay Biotech

The leading domestic bio-based nylon company uses glucose fermentation to produce cadaverine, with core products including PA56 and PA510. The current production capacity is 100,000 tons per year, and a 900,000-ton project is under construction in Taiyuan. In 2025, the company will collaborate with CATL to develop bio-based composite materials.

Golden Hair Technology

Through solid-phase suspension polymerization technology, the industrialization of bio-based high-temperature resistant polyamide PA10T was achieved globally for the first time. The Vicnyl® series products, including series 61 and 7, are bio-based high-performance semi-aromatic polyamides with a bio-carbon content ranging from 40wt% to 60wt%. The company currently has the capacity to synthesize 21,000 tons per year of high-temperature nylon (PA10T, PA6T).

YiPin Bio

Using industrial corn to ferment PA56 (Ecolon®), with a biobased carbon content of 48% (USDA certified). The current production capacity is 20,000 tons per year, and a second phase 100,000-ton project is expected to be operational in 2026.

LG

Cooperate with CJ First Sugar to produce PA56 (Earthyle™) from corn/sugarcane, applied in sportswear and automotive interiors. A new bio-based nylon material will be launched in 2025.

Developed 100% plant-based nylon 5,10 fibers (Ecodear™ series) for outdoor apparel. Launched bio-based nylon 5,10 in 2022.

Lantich

Launch of PA610 (Radilon® D series) and PA56 (Radilon® P), castor oil-based materials, reducing environmental impact by 50%.

Shandong Xianglong

Focused on the research and production of high-end bio-based nylon materials such as bio-based long carbon chain transparent nylon, special long carbon chain transparent nylon, and high-temperature resistant transparent nylon. A series of bio-based transparent nylon materials with over 90% light transmittance, low-temperature resistance, creep resistance, and strong chemical resistance have been developed.

Dongchen Ruisen

The bio-based nylon products developed by Dongchen Ruishen use renewable plant materials and are widely used in environmentally friendly clothing fibers, low-carbon packaging films, and green electronic casings. The company currently has a bio-based polyamide production capacity of 100,000 tons per year, with an additional capacity of 900,000 tons per year under construction.

4. Conclusion

The current domestic bio-based nylon industry presents a pattern of "sufficient basic capacity, insufficient high-end supply." Although conventional varieties such as PA56 and PA1010 have achieved large-scale production capacity, there is still a significant supply-demand gap for PA10T, which has a higher technical threshold. The commissioning of the project by Kingfa Sci & Tech holds dual significance: on one hand, it will fill the gap in domestic high-end bio-based nylon production capacity; on the other hand, through breakthroughs in material performance (such as dielectric loss ≤0.008), it will provide key material support for frontier fields like 6G communication and AI equipment. This initiative not only improves the domestic new materials industry chain but also signifies that China has acquired the technical capability to compete on par with international chemical giants in the field of specialty engineering plastics.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track