Global Perspective: Building a Fully Intelligent Purification System

In the midsummer of Hefei, more than 80 sets of equipment, including plastic sorting machines, are running at high speed in the Zhongke Optoelectronics Plastic Sorting Testing Center. Whole bottle sorters, daily miscellaneous material sorters, and high-end particle sorters are lined up in different areas. The site features both mature models that have been put into production and the latest achievements still under testing.

Deputy General Manager Wang Hong stood between the equipment, introducing it to us.The technological landscape of Zhongke Optoelectronics in the field of renewable resource sortingFrom whole PET bottles to flakes, from rigid mixed plastics to high-end particles, forming a full-process coverage intelligent sorting system.

— 1 —

PET: From Barrier Agent to "Bottle-to-Bottle" Deep Purification

In recent years, one of the biggest pain points in the PET industry has been the mixing in of barrier agent bottles. These bottles are transparent at room temperature, but turn yellow when heated, affecting the quality of recycled sheets.

In 2025, Zhongke Optoelectronics will launch a complete bottle and flake sorting technology for barrier agents, utilizing multiple methods such as label recognition, fluorescence aging sorting, and material decomposition to precisely remove barrier agent bottles. Under different impurity ratios, the impurity content can be gradually reduced from 15,000 ppm to 500 ppm or even 300 ppm, providing assurance for export-grade products.

Wang Hong emphasized that this is not only driven by customer demand, but also by industry goals: "Customer satisfaction is our pursuit, but we aim to set higher purity standards for the industry."

— 2 —

Daily sundries and rigid mixed plastics: Customized problem-solving approaches

Unlike the relatively single component of PET, daily miscellaneous materials and rigid mixed plasticsThe combination of materials is complex and the proportions fluctuate greatly.。

Zhongke Optoelectronics adoptsFull-spectrum detection + customized process sectionAccording to the characteristics of the customer's materials, we tailor the configuration of equipment for each stage. For example, for PP, both flame-retardant and non-flame-retardant types, as well as homopolymer and copolymer, need to be separated; for PE, high-pressure and low-pressure types need to be separated.

The goal is not just 98% purity, but to get as close as possible to the performance of virgin materials, allowing recycled materials to be directly returned to their original uses— "bottle caps for bottle caps, refrigerators for refrigerators."

— 3 —

Market Strategy Starting from Scrap Material

When Zhongke Optoelectronics entered the plastic sorting field, it did not directly target the fiercely competitive mainstream market but instead chose tailings—those low-value, high-difficulty raw materials that mainstream manufacturers were unwilling to handle.

By solving the purification challenges of leftover materials, the company established a technological barrier and gradually expanded into multiple niche areas such as polyester, daily necessities, and high-end particles.This "flanking breakthrough—gradually entering the mainstream—feeding back into the original field" pathThis gives Zhongke Optoelectronics a unique advantage in the competition.

— 4 —

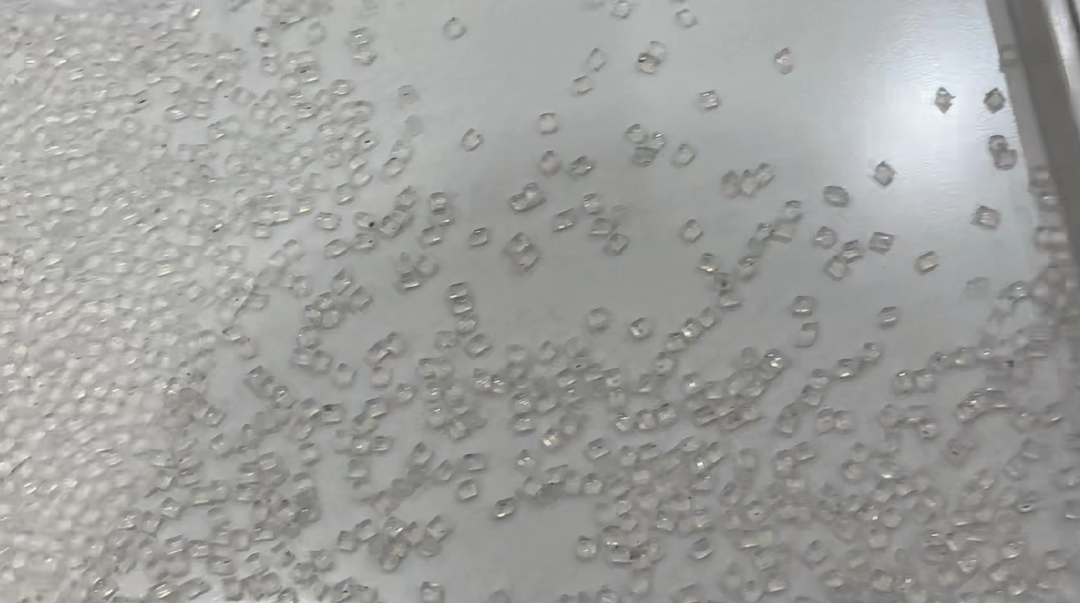

High-end particle sorting: Invisible black dots

In the production of high-end plastic products, even a black spot of 0.8 millimeters can cause the entire batch to be scrapped.

Zhongke Optoelectronics' AI Particle SorterDetectable even by the naked eye, tiny black spots and discolored particles.It is suitable for applications with extremely high surface quality requirements, such as automotive parts and food-grade packaging.

Wang Hong gave an example that the equipment can purify POM from 97% to nearly 99%. Although this seems like an increase from "0.1 to 0.2," it is the result of a tremendous technological investment.

— 5 —

Intelligentization of the entire process and advancement of quality inspection.

Traditional plastic recycling relies mostly on end-product quality inspection.Real-time quality inspection and feedback for all production stagesis the future direction.

Zhongke Optoelectronics sets up inspection ports at each stage of the production line, instantly feeding back inspection data to the equipment to enable dynamic adjustments and reduce labor and inspection costs.

This model has been extended to both the procurement and delivery ends—customers can be equipped with self-inspection machines to accurately assess raw materials and products, thus avoiding losses caused by inaccurate valuation.

— 6 —

Industrial Ecologization and Global Perspective

Hefei has become a hub for optoelectronic sorting equipment in China, withOrigin advantage, talent advantage, and supporting advantage。

Globally, China's recycling system has a wide coverage and high complexity, while Europe and the United States, despite strict control over raw materials, have relatively single scenarios. Wang Hong believes that this is actually an opportunity for Chinese technology to go international—“a full-scenario, full-series recycling environment is rare worldwide.”

— 7 —

Future technological directions

Precision Sorting of Black PlasticIt is now able to address certain scenarios (such as home appliances and automobile disassembly), and will continue to delve deeper in the future.

Automatic spreading of thin films and fabricsSolve the problem of uneven feeding of agricultural film, garment fabric scraps, and other materials.

Robotic Arm-Assisted Automated SortingImprove the handling efficiency of soft and irregularly shaped materials.

— 8 —

Technical Barriers and Industry Upgrading

Wang Hong spoke frankly.Technology is the industry barrier.In industries without mandatory entry requirements, only technology can achieve survival of the fittest and promote the industry to upgrade to higher standards.

"Your needs are our pursuit, but the industry's and international's goals are the ultimate goals we aim to achieve."

— 9 —

From leftover materials to high-end particles, from manual sorting to full-process intelligentization.Zhongke Optoelectronics has driven the fundamental upgrade of the plastic recycling industry through technology.。

Against the backdrop of global plastic pollution management becoming an international agenda, this is not only a company's competitiveness but also China's contribution to the circular economy.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track