Functions and applications of nylon aging resistance masterbatch

Nylon anti-aging masterbatch

Nylon Anti-aging MasterbatchIt is a high-concentration, high-efficiency functional masterbatch with nylon (polyamide) as the carrier. It uniformly disperses various anti-aging additives (mainly light stabilizers and antioxidants) into nylon resin through advanced processing technology to produce a granular product.

Its core function isTo endow or significantly enhance nylon plastic products with the ability to resist aging (photo-oxidative aging and thermal oxidative aging)....thereby extending the service life of the product.

Why does nylon need to be anti-aging?

Nylon itself has excellent mechanical strength, wear resistance, and chemical resistance, but its molecular structure contains amide bonds (-CO-NH-) and methylene groups (-CH2-) which are susceptible to oxygen, heat, especially.Ultraviolet raysVery sensitive. Aging can cause:

Appearance deteriorationDiscoloration, yellowing, loss of luster, surface cracking.

2. Decrease in mechanical performanceStrength, toughness, and elongation decrease, causing the product to become brittle and prone to breakage.

3. Degradation of electrical performanceThe insulation performance deteriorates.

Therefore, nylon products used outdoors or in high-temperature environments for extended periods (such as automotive parts, outdoor sports equipment, electronic and electrical components) must incorporate anti-aging masterbatches.

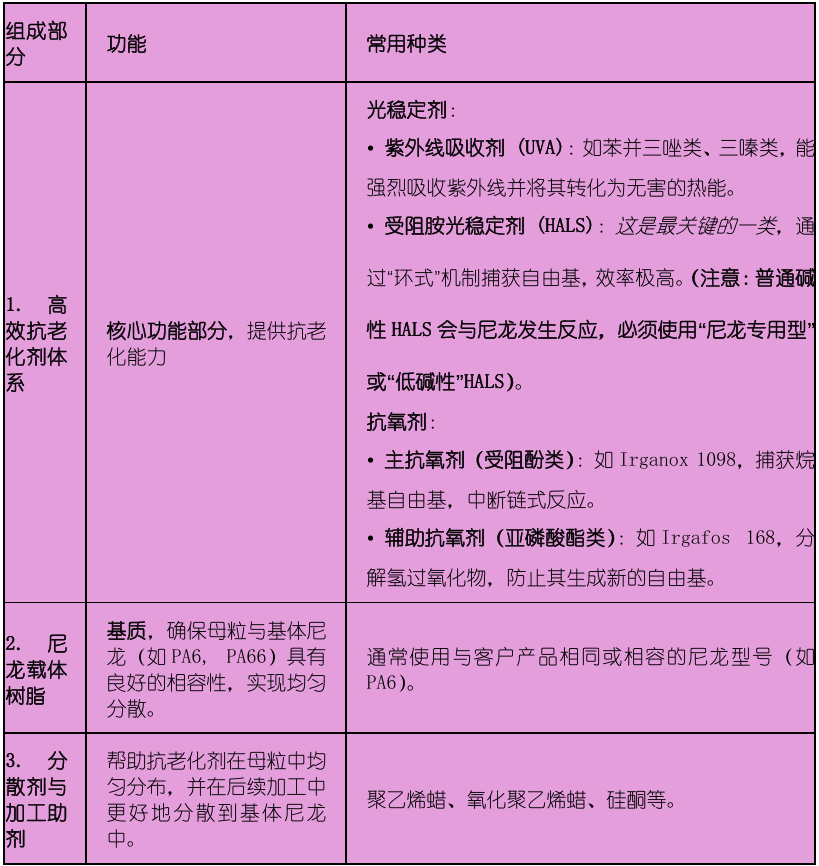

The core components and mechanisms of anti-aging masterbatch.

Main Functions and Advantages

Extend product lifespanSignificantly delays material degradation caused by light and heat, enabling products to be used for extended periods even in harsh environments.

Maintain appearance and performanceTo prevent yellowing and embrittlement, and to maintain the initial color, gloss, and mechanical strength of the product.

Improve processing stabilityProvide thermal oxidation protection during high-temperature injection molding, extrusion, and other processing to prevent polymer degradation.

Convenient to use, well-dispersed.Adding in the form of masterbatch is more convenient than directly adding powdered additives, as it is dust-free, accurately metered, and has far superior dispersion uniformity compared to direct mixing.

Cost-effectiveAlthough the cost of masterbatch has increased, the overall cost is reduced by decreasing the defect rate and extending the product lifespan.

Typical application areas

Automobile IndustryEngine peripheral components (fans, covers), outer door handles, exterior mirror housings, connectors (harness clamps), etc., need to be resistant to high temperatures and weather.

Outdoor gearOutdoor lighting fixture housings, sports equipment (such as ski bindings), garden tool components.

Electronic appliancesCircuit breaker enclosures, sockets, connectors for outdoor use.

Industrial sectorMechanical parts and pipe fasteners exposed to the outdoors for a long time.

How to choose and use?

1. Select according to nylon typeEnsure that the masterbatch carrier is compatible with your base material (such as PA6 or PA66).

2. Clarify the usage environment:

Outdoor use, primarily for illumination.NeedUV stabilizer (UVA+HALS) AntioxidantComposite system.

Use in high-temperature environmentsEfficiently needed.Antioxidant system。

Harsh environments (such as under a car hood)NeedLight and heat stabilizersA powerful combination.

3. Follow and add ratioThe usual addition ratio is 1% to 3%. The specific ratio needs to be determined through testing according to the concentration of the masterbatch and your performance requirements.

4. Pay attention to the processing technology:

Mix evenlyBefore injection molding or extrusion, thoroughly mix the masterbatch with the nylon base material.

Avoid over-processingExcessive processing temperature and prolonged residence time may lead to the decomposition or volatilization of some additives, affecting their effectiveness.

Nylon anti-aging masterbatch is a key product in modern polymer material modification technology. It efficiently and conveniently addresses the inherent defects of nylon materials. For high-quality nylon products with weather resistance requirements, it is not "optional" but a "necessity" to ensure product quality and reliability. When selecting, be sure to communicate with a reliable supplier to clarify your specific application scenarios and technical requirements.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track