Full throttle! lexus golden state factory has transformed like this!

The strong northwest wind fiercely tears at the flag of China Railway Fifth Bureau, causing it to flutter loudly, while also blowing up the dust and sand on the exposed ground of the construction site, swirling into the sky like clouds of gray smoke. This scene, set against the backdrop of a forest of cranes and boom arms, accompanied by the full-throttle roar of earthmoving trucks, creates an illusion of stepping onto the battlefields of Hexi a thousand years ago.

Last Wednesday afternoon, after setting off from the commune office, we drove for over an hour to reach the site of the under-construction Lexus Jinshan factory. At noon, the Jinshan District Meteorological Station issued a blue alert for strong winds. By the time I arrived at the scene, a gale with wind speeds of force seven had already started.

Before departure, there was constant worry about the heavy rain, which did not actually fall. On the contrary, the gusts of wind added an atmosphere to the construction site, reminiscent of a battlefield.

01Lexus' first overseas new energy factory

Actually, as early as July 1st, the fourth day after the official commencement ceremony, I had already visited this place once. However, at that time, I did not see the bustling construction scene I had been expecting.

The excavator decorated with ribbons and a large red flower, which appeared in the news about the launch ceremony, is parked in a corner of the construction site. Looking from the entrance, one can only see from a distance the presumed central area of the future factory building, where earth excavation work is underway. On one side of the construction site, a row of large-diameter precast concrete pipes is neatly arranged.

After communicating with the on-site staff, it was learned that the scene of "full-speed ahead" would take some time to be seen. On one hand, it was due to the weather, as the rainy season hadn't ended yet, and the site needed some time to dry. Additionally, the project still needed to complete some necessary procedures at that time.

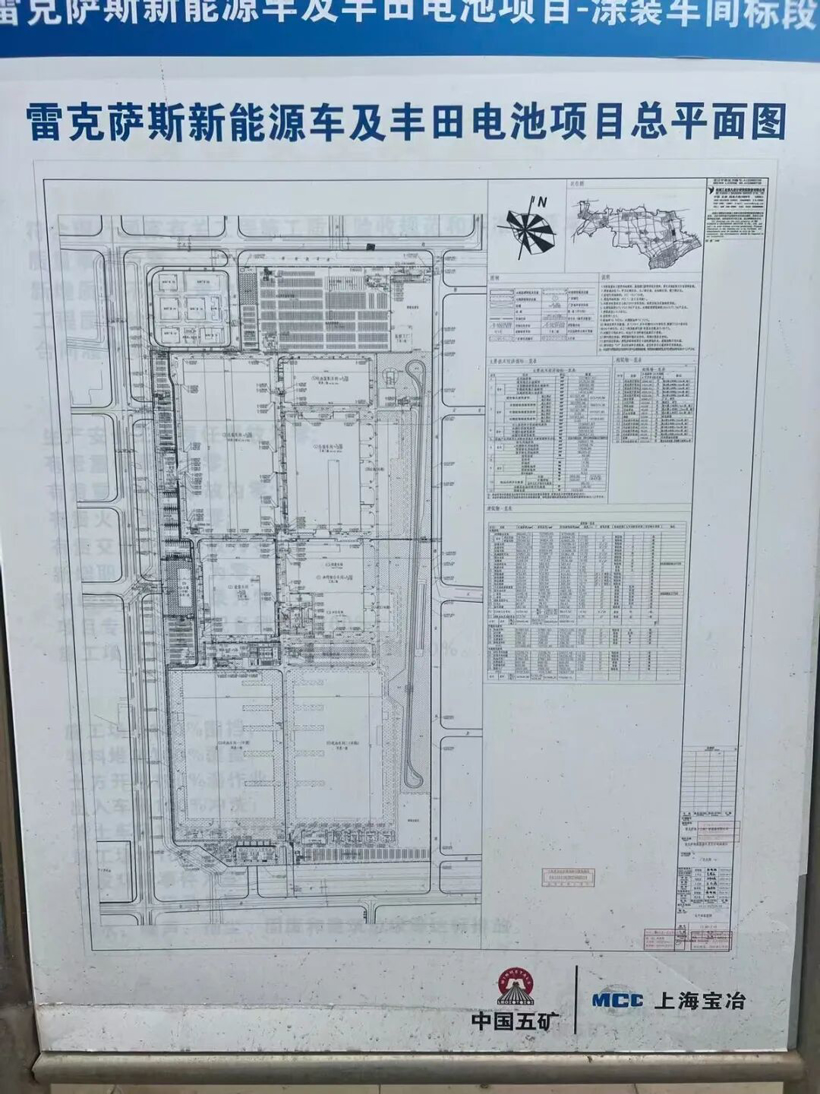

Last Wednesday, at the main entrance of the already closed construction site on Tingwei Road and Tiangong Road, those "documents" were prominently posted on the bulletin board, just like at most construction sites nowadays, making all detailed information directly available to the public.

The total land area of the entire project reaches 1,127,837.43 square meters. In comparison, the land area of the Tesla Gigafactory in Shanghai is approximately 865,000 square meters. The land area of the Lexus Jinshan plant is slightly less than one-fourth larger than before.

The total area of construction land is 553,534.98 square meters, with 308,160.48 square meters for this phase. According to the plant layout, the main buildings of the production base include five workshops: battery assembly workshop, die-casting workshop, stamping and welding combined workshop, painting workshop, and final assembly workshop.

The project consists of medium-term and long-term components, with building areas of 107,321.9 square meters and 141,913.6 square meters respectively. According to the current plan, the additional capacity for both the medium-term and long-term is for battery production.

The information reveals several other details upon closer inspection. For instance, the construction and planning permit issued by the Jinshan District Planning and Natural Resources Bureau was dated July 28th. The construction permit issued by the Jinshan District Construction and Management Committee was dated August 8th.

It is noteworthy that the construction permit specifies a contract period of 457 calendar days, roughly equivalent to about one year and three months. This means that by around November 2026 at the latest, the Lexus Jinshan plant needs to complete all the civil engineering work. As announced at the construction commencement ceremony, taking into account the time required for equipment installation, commissioning, and trial production, the plant is expected to officially start production in the first half of 2027.

As for now, based on what was observed on-site that day, the construction progress is still at the foundation and groundwork stage.

02Toyota will gain infinite benefits from it.

Although the initial planned annual production capacity is only 100,000 units, Toyota's establishment of a wholly-owned Lexus electric vehicle factory in Shanghai's Jinshan District is significant enough to be considered one of the most major events in China's automotive industry this year.

There are two reasons—

This is not only Toyota's first wholly-owned new energy plant in China but also marks the first time the Lexus brand will achieve localized production in China. During the heyday of joint ventures, Chinese car owners had hoped for many years for Lexus to be produced domestically, oscillating between "never localizing" and rumors of localization. Now, there is finally a clear result. Although times have changed, the establishment of this wholly-owned plant is, at least, the realization of years of anticipation.

On the morning of April 22, the Shanghai Municipal Government and Toyota Motor Corporation officially signed a strategic cooperation agreement, and the Jinshan District Government and Toyota China signed a memorandum of cooperation.

Furthermore, at this current period, Toyota has ended its wavering phase in new energy and intelligence, and has firmly chosen to embrace the trend. The company has even officially stated its intention to "embark on a path of 'inheritance and evolution' in the Chinese style." Additionally, at the beginning of this year, Toyota began implementing the "China Chief Engineer (RCE)" system. If the above represents Toyota's commitment to transformation in terms of policy and decision-making, then the Lexus Jinshan plant symbolizes concrete actions on the operational level.

Toyota has demonstrated its commitment to China, the world's largest new energy vehicle market and the fastest place for technological iteration, with real actions and substantial investments. By establishing wholly-owned factories, Toyota can directly control research and production, enabling a quicker response to the demands of Chinese consumers. The goal is to "reflect Chinese customers' expectations into products at China's speed."

In comparison to the scale of the Lingang Gigafactory, it can be assumed that the maximum production capacity of the Lexus Jinshan plant will be no less than 500,000 vehicles per year. Therefore, in Toyota's plan, this plant will serve as a hub for integrating the Chinese intelligent electric vehicle industry chain and will undertake the pioneering mission of the global electrification strategy. It will not only produce pure electric models but also develop and manufacture advanced power batteries, with plans to apply cutting-edge technologies such as solid-state batteries.

Image: Tesla's Lingang Gigafactory, which has now become an industry benchmark.

In this era where China's domestic new energy and intelligent capabilities are fully recognized by global car companies, Chinese local models will become the foundation for the next phase of global models for various groups. In this regard, Toyota is arguably ahead of all global competitors.

03A model project of mutual benefit for all parties involved.

At this critical juncture, establishing a production base for its high-end brand in China is indeed a smart move for Toyota. However, the beneficiaries are not limited to just one company. Whether it's the Chinese automotive industry or the Shanghai local government that approved the establishment of the Jinshan plant, this is essentially a multi-win project.

From a broader perspective, with Lexus ending its twenty-year import model, it is bound to further serve as a model and drive more global high-end automotive brands to establish a presence locally.

The picture indicates that China's automotive supply chain is already strong enough, and the next step is to fully break through towards high-end development.

This will further strengthen Shanghai's image as an "open window" within China's system, playing a more significant bridging role in the current domestic and international dual-circulation system. After all, this is the second wholly foreign-owned new energy vehicle project introduced in Shanghai after Tesla, not only proving the attractiveness of Shanghai and even China for high-end foreign investment projects, but also serving as a successful practice of the policy of opening up. From the perspective of the domestic new energy vehicle industry, the establishment of the Lexus Jinshan factory will also consolidate Shanghai's position within the domestic automotive industry.

Looking inside the automotive industry, the establishment of this important production base will further drive the upgrading of the industry chain and cluster effect. According to the plan, Toyota hopes to eventually achieve a local component ratio of over 95% at the Lexus Jinshan plant.

Certainly, the current supply chain for new energy vehicles in China has already been activated, and there is no lack of "quantity" to further drive qualitative change. However, how to "expand outward" is the primary issue at present. After all, although the annual sales figure of 30 million is substantial, it pales in comparison to the global market, which has a scope of 50 to 60 million vehicles. Furthermore, the establishment of the Lexus brand in Shanghai's Jinshan District is bound to deeply invigorate and drive the mature high-end new energy vehicle industry chain in the Yangtze River Delta region, and even promote the upgrading of the local supply chain to a higher-end level.

When will we be able to use Chinese standards and technology to create global models?

Since Toyota's official announcement in April this year, Shanghai's Jinshan District has become a focal point in the domestic automotive industry, according to previous reports from Shanghai media. So far, dozens of industrial chain enterprises from the Yangtze River Delta region and other provinces across the country have been attracted to explore cooperation opportunities. This agglomeration effect helps optimize the industrial structure of the entire region.

From a purely Shanghai local perspective, the project's contribution to economic growth and job opportunities is equally significant. Once the Lexus Jinshan factory is completed, it will not only provide substantial long-term tax revenue but also directly create tens of thousands of new jobs locally. Additionally, it will stimulate several times that number of ancillary employment opportunities. In fact, even at the current preliminary construction stage, ongoing construction investments and related procurement have already begun to inject sustained momentum into the local economy.

The solid-state transformation of power batteries has now become a widely recognized trend for the next stage of development in the industry.

Leading domestic companies such as CATL, BYD, Gotion High-Tech, Ganfeng Lithium, and Qingtao Energy are currently making intensive preparations and have each presented their mass vehicle installation roadmaps, with 2027 being a key milestone.

Image: Solid-state batteries are approaching their breakthrough moment.

However, despite the fact that current Chinese power battery companies are continuously expanding by leveraging their scale advantages, Toyota, as a veteran company in the industry and one of the few that can compete with Chinese rivals, should not be underestimated. After all, in the field of solid-state batteries, Toyota holds thousands of patents. Now, the related technology will come to China along with the establishment of the Lexus Jinshan factory.

According to the official statement, the new factory will adopt "revolutionary innovative production technology." In addition, through this production base, Toyota is highly likely to engage in comprehensive cooperation with domestic enterprises in fields such as power battery recycling and reuse technology and hydrogen energy. After all, Jinshan Petrochemical, located directly south of the factory, is the leading supplier of industrial by-product hydrogen in the country. Moreover, Jinshan District itself is one of China's hydrogen energy demonstration bases.

Image | Everything will begin from here!

There is no doubt that the construction of the Lexus Jinshan plant is a key move in Toyota's electrification strategy and a landmark event in the globalization process of China's new energy vehicle industry. It demonstrates the strong appeal of Shanghai and China in high-end manufacturing and an open business environment.

In the future, this factory will not only produce advanced pure electric vehicles but also potentially become a source of cutting-edge technologies such as solid-state batteries and a model of deep integration between Chinese and foreign industrial chains, driving the Chinese automotive industry to climb higher on the global value chain.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track