From "Product Output" to "Service Rooted": More Than Equipment, But Local Partners

Challenge

The dual demand for efficiency and accuracy.

In Kocaeli, Turkey's industrial hub, Shinko, a manufacturer of automotive parts and electrical equipment, is swiftly advancing towards a new phase of capacity expansion. Shinko has an almost stringent demand for every detail in the production process—from the stability of injection molding equipment, molding precision, to the operational efficiency of the entire production line. Any shortcomings in these areas could affect their delivery commitments to customers. At the beginning of 2024, as market orders continue to grow, Shinko's capacity bottleneck becomes increasingly apparent, triggering a revolution aimed at expanding production with efficient, high-precision, and high-quality injection molding solutions.

When the management of Shinko Company turned their attention to the global injection molding equipment market, their core demand was clear and precise: they not only needed a batch of equipment capable of high-load precision production but also required a partner who deeply understood industry characteristics and could provide long-term reliable support. It was under the alignment of these needs that Haitian International and Shinko began their collaboration.

Fu Ze

Rooted in technology, advancing together through service.

The Haitan International team conducted in-depth research on Shinko's production pain points and tailored a comprehensive solution centered around the Haitan MAV series servo injection molding machine for Shinko.

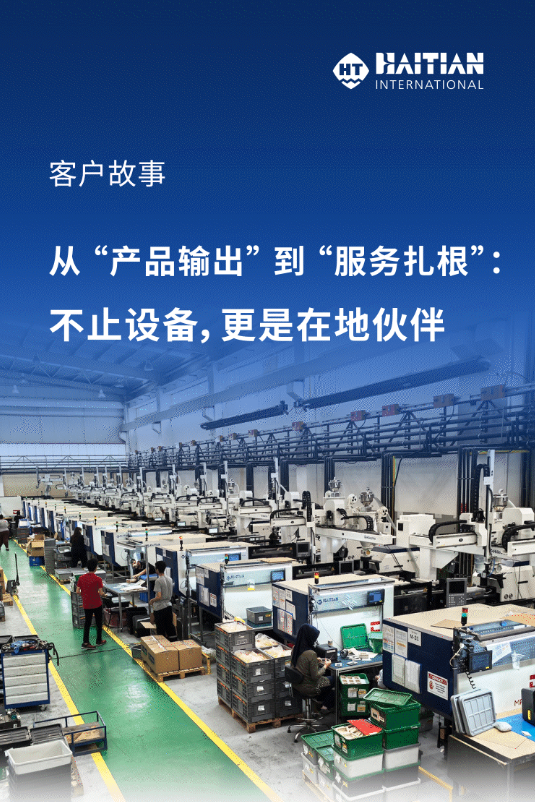

Shinko's production workshop

The high-response servo system has become the "core engine" of production, significantly reducing energy consumption while maintaining the stability of the molding cycle within rigorous standards, perfectly matching the dimensional accuracy requirements of automotive parts. The intelligent integrated control system achieves seamless coordination between the injection molding machine and the accompanying robotic arm, enhancing automation not only reduces errors caused by manual intervention but also leads to a qualitative leap in the operational efficiency of the production line. What reassures Shinko the most is the localized service support provided by Haitian — Haitian International has established a technical service center in Turkey, responding to fault resolution within 24 hours and providing long-term process optimization services to ensure the equipment is always in optimal operating condition. This is not merely after-sales assurance but a long-term commitment to jointly safeguarding production continuity with Shinko.

After multiple rounds of performance testing and cost analysis, the Shinko technical team confirmed that Haitian equipment outperforms competitors in molding precision, energy consumption control, and long-term operational stability. The company's general manager stated, "Haitian not only provides equipment but also offers sustainable upgradeable production solutions."

Result

Efficient operation, partnering for a sustainable future

Nowadays, all 16 Haitian injection molding machines purchased in one go have been fully installed and commissioned, running smoothly on Shinko Company's automotive parts and electrical equipment production lines. Actual operational data provides the strongest evidence: production efficiency has increased by approximately 22%, and the product defect rate has been reduced to below 0.3%.

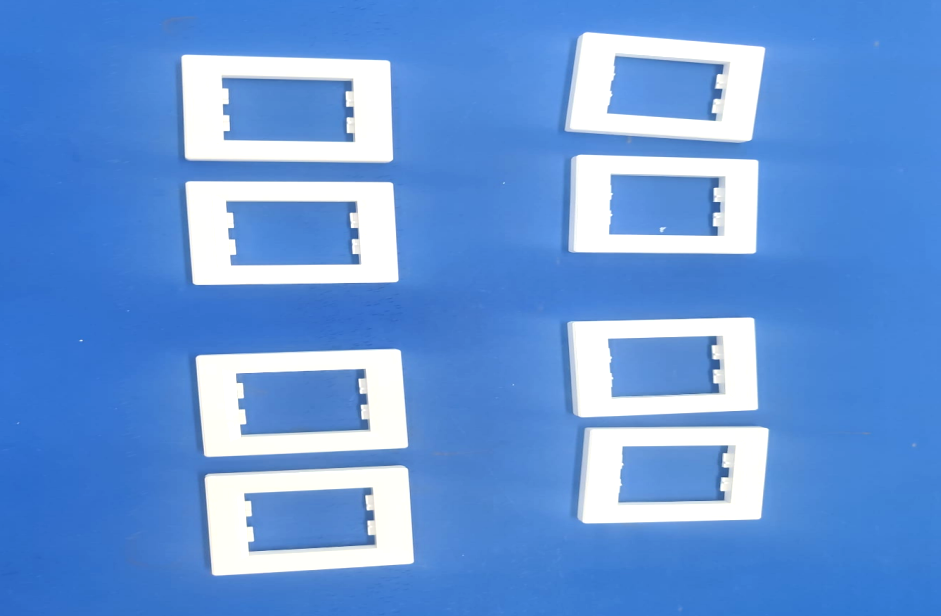

Shinko Company Products

Shinko's procurement director emphasized, "This cooperation is not just about equipment procurement; it marks the beginning of a long-term strategic partnership between Haitian and Shinko. We look forward to continuing to work together in future expansion plans." Behind this trust lies Haitian International's deep commitment to the concept of globalization—Haitian International firmly believes that true globalization is not about selling products globally, but about leaving value in the local area.

Conclusion

From "Product Output" to "Service Rooted"

Group photo of both parties.

In the production workshop of Shinko, the smooth operation of each Haitian injection molding machine vividly illustrates "localized value": Haitian International leverages technological leadership and localized service strategies, with reliable quality as the foundation, customer needs as the center, and timely service as the guarantee, providing solid equipment support for the industrial upgrade of local enterprises. This allows the quality and service of Chinese manufacturing to "take root," deeply integrating into the context of Turkey's industrial development.

In the future, as Shinko continues to grow, Haitan will also provide solutions that better meet local needs, jointly writing a chapter of precise empowerment and mutually beneficial cooperation.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Dow, Wanhua, Huntsman Intensively Raise Prices! Who Controls the Global MDI Prices?

-

Clariant Unveils Cost-Cutting Plan Details, Plans to Shut Down Multiple Plants

-

New Breakthrough in Domestic Adiponitrile! Observing the Rise of China's Nylon Industry Chain from Tianchen Qixiang's Production

-

Nissan Cuts Production of New Leaf EV in Half Due to Battery Shortage