From Anhui to Sanming, Regenerated Polyester Project “Taking the Lead”

In 2025, the "champion-based" model for manufacturing innovation will shift its focus towards the field of recycled materials. Recently, Anhui and Sanming have intensively announced key research tasks, with three major projects directly targeting the critical issues of "high-value utilization of waste plastics," "carbon fiber recycling," and "functionalization of polyester fabrics." These initiatives aim to break through industry technical bottlenecks and support the "dual carbon" goals.

— 1 —

Anhui Makes a Strong Move: Three Major Recycled Materials Projects Set the Benchmark as "Domestic Leaders"

On September 3rd, the Anhui Provincial Department of Industry and Information Technology released the announcement of the guiding directory for the 2025 manufacturing "Revealing the List and Taking Command" talent recruitment and special research projects. After procedures such as enterprise applications, city recommendations, and expert evaluations, 328 tasks are proposed to be included in the 2025 manufacturing "Revealing the List and Taking Command" directory. Among them, 3 projects on recycled polymer materials have clear technical indicators, covering the three fields of automotive, high-end materials, and textiles.

Serial Number 258: Research and Application of High-Value Recycling and Thermochemical Conversion Integrated Utilization Technology for Automotive Waste Plastics

1. The accuracy of waste plastic identification and sorting is ≥95%;

The retention rate of mechanical properties for high-performance recycled plastics is ≥85%, and the VOC emission meets automotive standards.

The thermochemical conversion rate of plastics is ≥90%, and the yield of combustible gas/hydrogen is ≥60%.

4. The proportion of recycled plastics used in the whole vehicle is ≥25%;

Meet the material safety and environmental protection requirements of the EU ELV Directive and REACH regulations.

Serial Number 259: Technical Research on High-value Recycling of Waste Carbon Felt for Secondary Formation of Carbon Fiber Felt and Preparation of Porous Carbon Bricks

Technical specifications for secondary felting of recycled carbon fiber: density lower than 0.25 g/cm³ to ensure the lightweight characteristics of the carbon fiber felt; compressive strength higher than 10 MPa to guarantee a certain level of compressive resistance; product yield higher than 80% to control production losses and ensure production efficiency.

Technical specifications for preparing porous carbon bricks from recycled carbon fibers: The density should be between 0.9 - 1.1g/cm³ to ensure moderate product density; the flexural strength should be higher than 8MPa, and the compressive strength should be higher than 10MPa to meet certain strength requirements; the yield should be higher than 60% to balance production efficiency and quality.

Serial Number 260: Collaborative Research on Key Technologies and Industrialization Demonstration of High-Quality and Functional Recycled Polyester Fiber Fabrics

This project breaks through the key technological bottlenecks of recycled polyester fibers: Sub-project 1 develops recycled polyester fibers with dope-dyed technology in more than four colors, achieving a strength retention rate of ≥90% (national standard GB/T3923.1-2013), which is 5% higher than the industry average. Sub-project 2 pioneers the technology of bio-based nano-finishing agents, achieving an LOI value of 33 vol%, V-0 level flame retardancy, an antibacterial rate of >99%, with 90% retention after 30 washes, and a surface resistance of 10^6-10^11Ω. Innovative development has formed a core technology system (1 new product, 3 new processes, 4 new devices), with 25 patents filed (including 2 PCT international applications), and 2 enterprise standards established, along with the construction of dual demonstration lines for spinning and fabric. Compared to the traditional processes of Sanfangxiang Group, the chemical recycling high-precision filtration device and bio-based modification technology significantly enhance product stability and functional durability.

After reaching full production, it is expected to generate an additional output value of 300 million RMB, boost the recycling rate of waste textiles in Anhui by 15%, form a 1 billion RMB circular industry cluster, reduce CO2 emissions by 80,000 tons annually, and contribute to the goals of a "zero-waste city" and "dual carbon" targets, with technical indicators reaching the leading level domestically.

— 2 —

Sanming Follow-up: Waste Polyester Recycling Project Fills the Gap in "Regional Circulation"

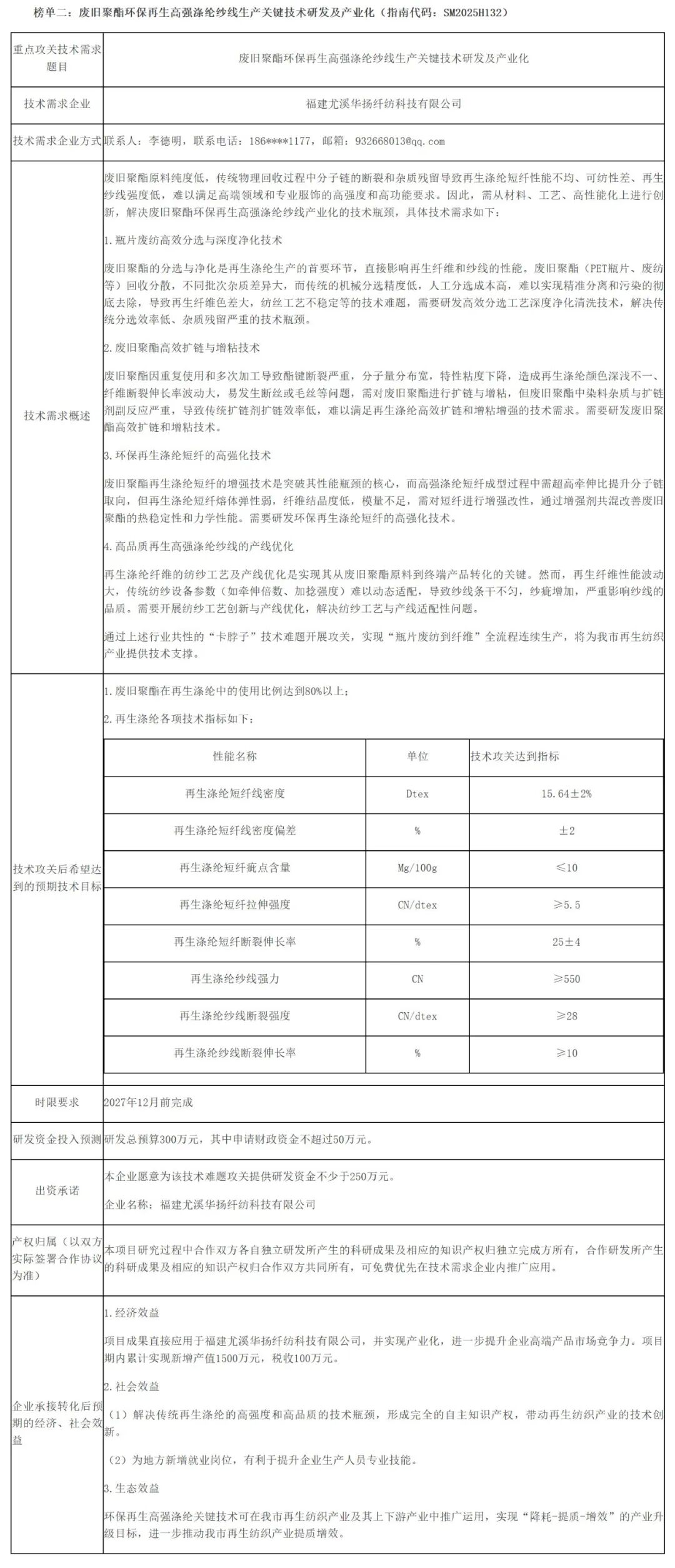

September 10, Sanming CityThe Bureau of Science and Technology issued a notice on the Announcement of the 2025 "Revealing the List and Taking Command" Project List in Sanming City.List Two: Research and Industrialization of Key Technologies for the Production of High-Strength Polyester Yarn from Waste Polyester for Environmental Recycling (Guideline Code: SM2025H132)

— 3 —

Why have recycled materials become the focus of "open competition for leadership"?

"The 'Revealing the List and Taking Command' system, also known as the technology reward system, addresses the disconnect between scientific research and application of results through an open collaborative model of 'heroes regardless of their origins.' Since it was first proposed in the 2020 government work report, it has become a key mechanism for overcoming 'bottleneck' technologies. Under the current policy direction of 'dual carbon' and 'waste-free cities,' recycled materials are a core approach to solving the 'resource shortage + environmental pressure' issue. The fields of waste plastics, carbon fiber, and polyester, which Anhui and Sanming are focusing on, are pain points in traditional recycling due to 'low utilization and low added value.' Through the open approach of 'Revealing the List and Taking Command,' not only can the implementation of technology be accelerated, but it can also promote the transformation of the recycling industry from 'low-cost recovery' to 'high-value upgrading.'"

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics