From 0 to 1: Building a Compounding Extrusion Production Line—Unveiling the Full Process from Planning to Commissioning

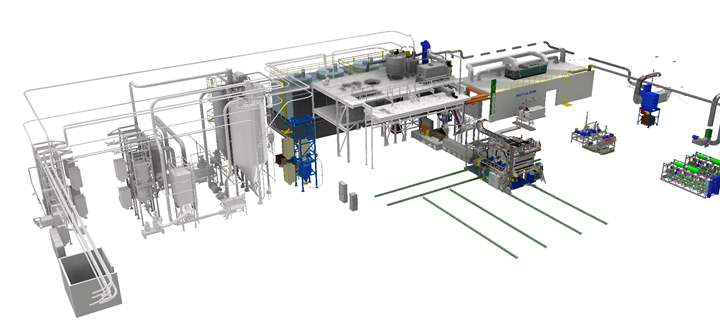

Adding a new compounding extrusion production line is a complex system engineering project, yet it can bring significant benefits. This requires a holistic approach to the project, comprehensively evaluating factors such as plant space, budget investment, and manpower allocation. The primary decision is whether to choose a single extruder assembled independently or to purchase a turnkey solution that includes a complete set of components.

1. Key Assessments Before Project Initiation

If a company already has experience operating extrusion production lines, it will have an advantage when setting up a new line. However, even seasoned compounding enterprises should be cautious of potential risks—for example, when producing pellet products with a new formulation for the first time, process compatibility may become a barrier to commissioning. At this point, it is necessary to balance process complexity with capacity expansion needs.

If the material demand is small and internal technology is mature, you can independently purchase an extruder and integrate the remaining compounding equipment yourself.

Turnkey solution: When the process involves multi-component coordination (such as 8-9 materials in loss-in-weight feeding), it is recommended to choose a full-process supplier, with supporting jacketed structures and material handling systems.

Taking a basic production line as an example, producing pellets containing color masterbatch requires only 5-6 types of raw materials to be fed into the extruder through a single feeder. Such production lines can be quickly replicated based on internal experience. In contrast, complex compounding processes that are completed entirely within the extruder must rely on engineering support from specialized suppliers.

2. Core Logic of Extruder Selection

As the heart of the production line, the selection of the extruder screw diameter needs to be combined with production capacity and raw material costs.

27mm screw: The ideal model for laboratory settings, suitable for small-scale research and development.

33-53mm screw: The most mainstream production model, suitable for most conventional production.

73-103mm screw: Large-scale granulation with an annual capacity of hundreds of thousands of pounds, requires a high-power motor.

The small-sized extruder shows significant advantages during the trial production phase: it produces less waste, making it especially suitable for high-cost raw materials; its changeover and cleaning efficiency are higher, making it ideal for multi-variety small-batch production.

3. Factory Renovation and Infrastructure Adaptation

A comprehensive evaluation of site conditions is required for the new production line.

Layer height requirement: 33-53mm extruders are compatible with standard factory buildings; for models with heights above 73mm, additional consideration must be given to the installation height of material lifting equipment.

Hydropower load: Large extruders (such as 73mm models equipped with 600-horsepower motors) often require additional transformers. This expense may lead companies to choose 53mm models to reduce renovation costs.

4. Selection of Installation Execution Strategies

The production line integration model directly affects implementation efficiency.

Decentralized procurement: Purchasing extruders, pelletizers, and other equipment from different suppliers separately, but it is necessary to address the communication compatibility issues between multi-brand equipment.

Turnkey procurement: A single supplier provides end-to-end equipment, which can significantly reduce system integration risks.

5. Precise Control of the Feeding System

In a dual feeder scenario, formula stability is particularly crucial. For example, a ratio of 50% calcium carbonate + 50% polyolefin may lead to component deviations of up to ±10% if the feeder selection is inappropriate. Core principles include:

Loss-in-weight feeding preferred: standard configuration for most compounding lines.

Material compatibility: Powder materials require specialized feeders, while some models can accommodate granular materials by replacing the sieve.

Anti-sticking design: For easily agglomerated particles, a stirring function needs to be provided.

VI. Key Points of Equipment Maintenance

The extruder barrel and screw are the main wear components, and calibration deviation can lead to metal friction wear. It is recommended to establish a preventive maintenance mechanism.

Regular laser alignment inspection.

Access wear monitoring tool.

Follow the supplier's maintenance schedule (such as the transmission oil replacement interval).

7. The Golden Rules for Supplier Selection

An ideal supplier should possess full-chain technical capabilities, with particular emphasis on the following areas for assessment:

Predictive testing capability: ability to optimize equipment selection through material trial processing;

Understanding of granulation processes: suitable scenarios for underwater pelletizing and water strand pelletizing.

Quick Changeover Design: Whether solutions such as quick die/head change are provided to improve efficiency.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track