Frequent Thefts of Auto Parts in Europe and America: Plastics Targeted Alongside Metals

Specialized Plastics VisionOn September 4th, it was observed thatRecently, The region has been experiencing frequent theft incidents, with the theft of charging station cables in Germany being particularly severe, drawing significant attention from the industry. According to German electric vehicle charging infrastructure operators, the large-scale criminal acts of cable theft by criminals are severely impacting maintenance teams and suppliers, causing ongoing difficulties in repair efforts.

Specific data shows that there are approximately ... per day in Germany.Seventy charging cables were maliciously cut and stolen, with such thefts becoming more frequent and large-scale. Philippe Senona, CEO of Alpicronic, pointed out that the thieves mainly target copper-containing charging cables, as copper has become the primary target due to its high recycling value.

Germany's largest fast-charging network operator EnBWA spokesperson for EnBW further emphasized that the year 2025 has become the most severe year for theft issues in this field, with the frequency and extent of criminal activities reaching an all-time high.

Image source: EnBW

Charging piles were stolen, what are the"High-priced" materials

Charging stations are usually located in convenient places for drivers to quickly enter and exit, but this also provides opportunities for thieves. In particular, charging equipment in supermarket parking lots and other unattended areas at night has become a high-risk area for theft.

Plastic materials have already fully penetrated the key components of charging piles.—If the charging plug uses halogen-free flame-retardant glass fiber reinforced grade PA 6 material, and the cable sheath uses PVC or halogen-free flame-retardant elastomer—but the thief's target is not the plastic itself.

Image source: Kuai Technology

Data from German operators show that the value of copper contained in a single charging cable is approximatelyThe cost is 40 euros. Once stolen, the charging station usually takes two weeks to resume operation. Tesla has implemented special anti-theft measures: engraving the words "Property of Tesla Motors" on the copper wires inside the Supercharger cable, wrapping the cable with cut-resistant materials, and placing dye ink underneath. When the cable is cut, the splattered dye attaches to the tools used in the crime, making it easier for the police to track down the perpetrators.

In addition to metal parts, plastic components have also become targets.

However, plastic parts have also become targets for theft. Earlier this year, Zhuansu Shijie reported on Ford truck owners in Texas, USA, experiencing taillight theft incidents.34 pickup trucks were damaged, with total losses exceeding $92,000.

A single new taillight is priced as high asThe price exceeds $2,700, far higher than that of ordinary parts. These taillights are equipped with advanced electronic technology and blind spot monitoring sensors, but their design is flawed—LED taillights can be removed with simple tools and sold on the black market for a considerable price. According to Reddit, owners of the 13th and 14th generation F-150 and F-250 frequently share experiences of their taillights being stolen. Thieves can even lower the tailgate through small holes in the tailgate panel to access the screws and remove the taillights.

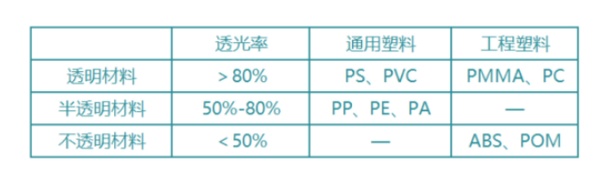

The choice of plastic materials for automotive taillights directly affects their performance and cost. Currently, taillights commonly useModified plastics such as PC, PP, PS, ABS, and PMMA are widely used, among which PMMA is an ideal material for auxiliary driving signal lights due to its 93% light transmittance, weather resistance from -60 to 100℃, and excellent impact resistance. For example, the key components of the tail lights on the Li Xiang ONE use Roehm's Plexiglas® Resist, which is the highest impact-resistant PMMA specification, enhancing impact strength while maintaining light transmittance, supporting the through-type tail light design.

The involved Ford pickup truck, image source: IT Home

Why are plastic car lights so valuable?

The headlamp consists of a reflector, lens, housing, light source, electronic circuits, and installation accessories. Internal control system components such as power modules, contactors, and circuit breakers are required to be halogen-free flame-retardant, electrically insulated, and dimensionally stable. They are usually made of halogen-free flame-retardant reinforced materials.PA or PBT materials. For cooling fans, it is recommended to use flame-retardant reinforced PBT or PPE materials to meet the requirements for heat resistance, low noise, and dynamic balance performance.

With the trend towards integrated headlight assemblies, through-type taillights place higher demands on material performance. For example, Dow's thermally conductive potting adhesive for charging guns.DOWSIL TC-6040 achieves rapid heat dissipation through high thermal conductivity, while sealants and sealing rings such as SiLASTIC™ RBB-6300-50 provide comprehensive protection. BASF Elastollan® TPU 1180A10WDM is specially designed for charging cables, combining flexibility, weather resistance, flame retardancy, and waterproofing. For cable assemblies, the inner protective layer can use halogen-free flame-retardant TPE or TPU, and the outer sheath uses PVC or halogen-free flame-retardant elastomers, meeting requirements for insulation, flame retardancy, weather resistance, crush resistance, and bend resistance.

In terms of the market,QYResearch predicts that the global smart car light market will reach a size of $11.3 billion by 2027, with a compound annual growth rate of 5.4%. However, the application of high-performance transparent plastics is still in its early stages, and the immature supply chain leads to high manufacturing costs for car lights. Consumers have mixed opinions about the high prices of new car lights, with some pointing out that the tail lights for the 2004 F150 were only $53, whereas the new plastic tail lights are priced at several hundred or even thousands of dollars, which is hard to understand. If car companies can lower the prices of tail lights, the motivation for theft might be reduced.

Source of the image: Automotive Lighting Accessories Expert

Epilogue:

From the copper used in charging piles to Ford taillightsPMMA, as a plastic material, enhances automotive performance but also becomes a target for theft due to its high value. With the expansion of the smart headlight market, the research and application of high-performance modified plastics need to mature further to balance cost and performance. For example, adopting more advanced modification technologies to reduce PMMA production costs, or developing recyclable high-performance plastics to lessen dependence on virgin resources. In addition, automakers can optimize designs to reduce the exposure risk of theft-prone parts, such as using more concealed fixing methods or integrating anti-theft sensors.

The current wave of auto parts theft in Europe has evolved from isolated incidents into a systemic social issue. Behind the frequent thefts is the high added value of plastic components circulating in the black market.For example, once the taillights of a Ford are dismantled, their special composite plastics can be quickly resold to the end of the repair chain; meanwhile, the copper recovery chain inside the plastic casing of charging piles further exposes regulatory loopholes in the resource recycling process. If this "theft-dismantling-resale" black market chain is not disrupted through targeted governance, it will continue to expand as the widespread use of plastic components increases with the trend toward automotive lightweighting and intelligence.

Specifically, it is necessary to constructA "trinity" prevention and control system: On the technical side, develop intelligent plastic materials with tamper-proof and traceability features, such as taillight components embedded with micro RFID chips, to achieve full-process monitoring from production to recycling. On the design side, optimize the mechanical structure of parts to increase the difficulty and time cost of disassembly, such as using integrated molded plastic brackets for bumpers, making it impossible to quickly dismantle without professional tools. On the supply chain side, promote deep binding between recycling companies and car manufacturers, establish officially certified recycling channels, and squeeze the profit margins of illegal dismantling. Only through such a collaborative governance approach of "material innovation-design optimization-supply chain maturity" can the incentives for theft be reduced at the source, curb the spread of the car parts theft wave in Europe, and ultimately achieve the dual goals of sustainable development in the automotive industry and social security.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track