[Focus on Germany K Show] Weimeng Group Unveils Multiple Innovative Injection Molding Machines

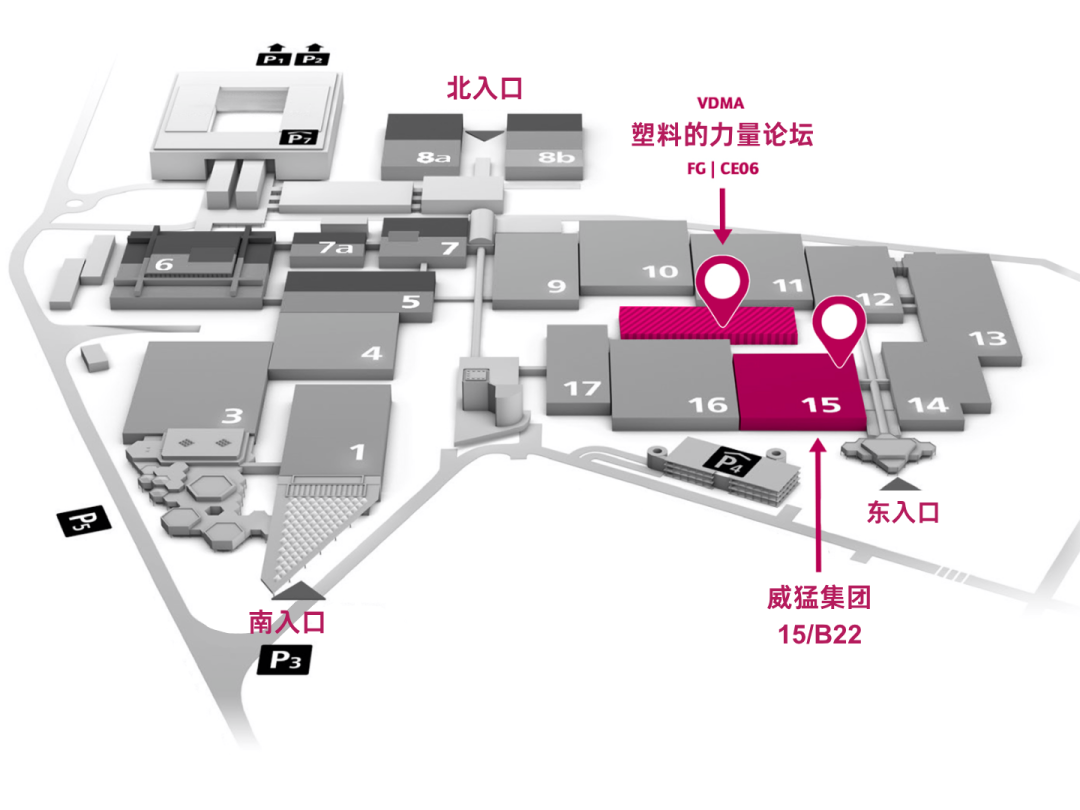

As one of the most influential events in the global rubber and plastics industry, the German K Fair (K 2025) will be grandly held in Düsseldorf from October 8 to 15, 2025. This industry event will bring together top rubber and plastics companies worldwide to showcase the latest technological innovations and industry trends.

Under this backdrop, Weimeng Group will make a grand appearance at booth B22 in Hall 15. With the theme "Smart Choices, Efficient Solutions," this exhibition will feature a unified booth design for the first time, showcasing its full range of products and diverse intelligent solutions. Through on-site demonstrations and professional explanations, Weimeng will illustrate to a global audience how intelligent choices can achieve dual optimization of resource consumption and production costs.

Powerful Debuts with Multiple Innovative Products

October 8 to 15, Düsseldorf, Germany.Wimove Group Multi-Booth Collaboration

As a key exhibitor, the Wittmann Group will showcase its latest R&D achievements at this year’s exhibition, with a focus on innovative breakthroughs in key technological areas such as space efficiency, energy economy, high-precision micro-injection molding, high-efficiency multi-component processing, and automated integration. Notably, the company will also participate in the "Power of Plastics" forum organized by the German Mechanical Engineering Industry Association (VDMA) in the E06 outdoor exhibition area, and conduct joint technical demonstrations in the partner exhibition area, comprehensively presenting its technological strengths in the field of plastics and rubber processing.

Hall 15, B22

Powerful Booth: Focused display of core injection molding equipment, technologies, and supporting systems

Momentive Partner Booth: Joint Demonstration of Liquid Silicone Rubber Technology Applications on SmartPower Injection Molding Machine

01.Hall 15 B22 Highlighted Equipment and Applications

A New Breakthrough in Spatial Efficiency

Injection molding machine model

• Powerful MacroPower 500/3400

Demonstration production

• HAIBOX enclosure (PP material)

Mold plan

- Austrian Haidlmair single-cavity mold

• Mighty In-Mold Labeling System

Technical Highlights

• The integrated body design optimizes space utilization.

• The rotatable injection unit simplifies the installation and maintenance process.

• The powerful B8X control system enhances response speed and repeatability.

• Thermal imaging device integrated with German SKZ software for automated quality inspection

Multi-component forming technology

Injection Molding Machine Model

• Weimeng MacroPower 650/2250H/1330H Combimould

Applications and Products

• Foldable Laundry Basket (PP+TPR Material)

Mold Plan

- Turkey ATA Kalip ve Plastik 1+1 cavity mold

Technical Highlights

• 1500mm turntable dual injection unit integration

• Compact layout reduces workshop space occupancy

• Mighty Primus 148T Robot Arm Automatic Picking

Fully electric, highly efficient, and energy-saving

Injection Molding Machine Model

- Weimeng EcoPrimus 100/525

Demonstration Production

Eye drop bottle sealing cap

Mold Plan

Austrian HTW 24-cavity unscrewing mold

Technical Highlights

• Efficiency Balance Design for All-Electric Models

- Equipped with the latest Weimeng B8X control system

• Seamless integration with Italy's Ravizza packaging system

Liquid Silicone Rubber (LSR) Technology

Injection Molding Machine Model

• VIMOS EcoPower 110/350

Application Products

• Liquid silicone seal pump casing

Mold Plan

• Austria Elmet 2-cavity mold

Technical Highlights

• Special optimized process for liquid silicone rubber

• Ensure the stable operation of TOP5100 metering pump

• Weimeng W918 robotic arm precise conveying

Compact Integrated System

Injection molding machine model

• Weimeng SmartPower 160/1000 Insider

Application Products

• PP aerosol spray cap

Mold Plan

- Austrian HTW 8-cavity mold

Technical Highlights

• Built-in design of robotic arm/conveyor belt

• WEIMENG WFC plus Water Flow Regulator

• Integrate the advantages of servo-hydraulic and electric technologies.

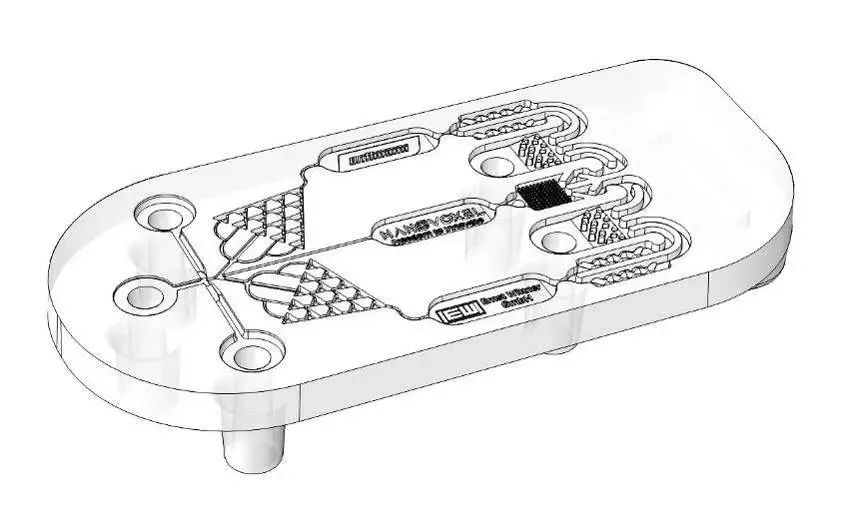

Micro-injection molding technology implementation

Injection Molding Machine Model

• Powerful Micro Injection Molding Machine MicroPower 15/10

Application Products

• Chip laboratory device (transparent PP)

Mold Solution

• Austria NanoVoxel 3D Printed Inserts

Technical Highlights

• The injection plunger directly reaches the mold parting line.

• Industry-leading solutions with near-zero waste

0.04×0.04×0.1mm microstructure molding

• 0.005mm extremely small corner radius

Automated production of in-mold decoration technology

Injection molding machine model

• Powerful Vertical Injection Molding Machine Vpower 160/525R1600

Application Products

• Decorative natural fiber components

Manufacturing Plan

German LEONHARD KURZ pre-decoration composite foil technology

• German FRIMO thermoforming lamination process

• German Polyvlies natural fiber substrate NFPP

Technical Highlights

- Double-rod turntable structure optimization to expand the operating space.

• Carbon reduction and emission mitigation through natural fiber substrate coating and molding

• Online Detection and Full-process Traceability System

Integrated Feeding System

All equipment achieves precise feeding through the integrated central material handling and control system by Weimeng.

Digital unified management

Intelligent Manufacturing Hub

• Exclusive TEMI+ workstation display: Demonstration of the TEMI+ production management program developed by Wittmann and the iMAGOxt energy management software

Intelligent operation and maintenance support

• Demonstrate the AIM4Help expert system pioneered by Weimeng, providing intelligent support for equipment operation and troubleshooting.

02.Outdoor Area E06 "The Power of Plastics" Forum

Responding to the theme of K ExhibitionPower of Plastics: Shaping a Green Future – Innovation, Excellence, and Shared Responsibility:

Green material applications

Injection Molding Machine Model

• Wyman SmartPower 350/1670

Demonstration production

• Insulated ice cream cone

Mold Plan

• German Precupa 4-cavity mold

Technical Highlights

Wafflerie patented fully food-grade natural plant-based materials

• Weimeng SmartPower precise, stable, and intelligent production

• Powerful Primus 128 robotic arm for non-destructive part removal

Solar Direct Drive: Recycled Plastic Molding Technology

Injection molding machine model

• Vimar EcoPower 180/750+DC Insider

Demonstration production

Wildflower Pot (Made from 100% Recycled Plastic)

Mold plan

• Single-cavity mold from Haidlmair, Austria

Technical Highlights

• Off-grid power supply with INESCO ecological salt batteries from Germany

The integration of solar energy direct utilization with electrical energy storage technology.

• WILDPLASTIC® Post-Consumer Recycled Plastic

• Powerful Cellmould foam weight reduction process

• TagTec invisible marking technology provides product traceability.

03.Hall 6, B15 Partner Booth

Powerful Joint Innovation with Momentive (U.S.)

Injection molding machine model

• VigorSmartPower 120/350

Demonstration production

Double-layer frisbee

Mold plan

• Austria ACH Solution 4-way valve gate single-cavity mold

Technical Highlights

• Liquid silicone injection molding technology

- BASF Ultramid B3S preformed substrate

• Overmolding with Momentive Siloprene LSR 2740 self-adhesive liquid silicone rubber

• Precise Control of ACH Four-Way Valve Gate

On-site Booth Map

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track