Fluorine-free wear-resistant new era! silike's fluorine-free wear-resistant agent overcomes eu ban to help nylon and pom challenge extreme lifespan!

The 2025 deadline for fluorine-free materials is approaching. Can the wear resistance upgrade of engineering plastics simultaneously cross the compliance red line and the cost cliff? New silicone-based wear-resistant agents offer a new solution.

The Material Revolution Under the Fluorine Ban

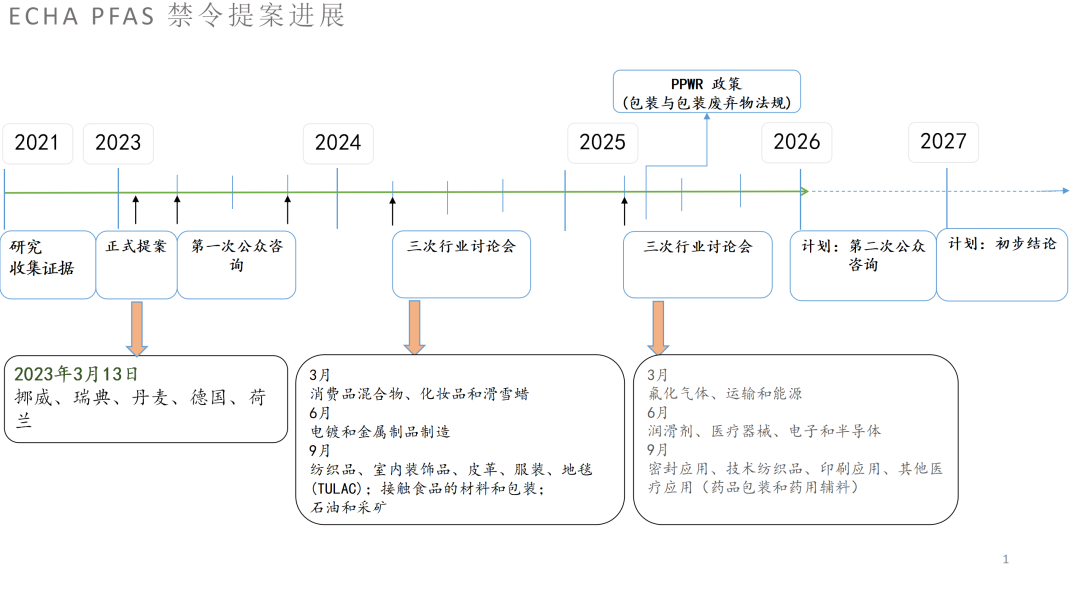

The 2023 EU PFAS ban (draft) targets over 6,000 fluorinated chemicals, putting traditional PTFE wear-resistant agents at risk of elimination. The mechanical, automotive, and electronics industries urgently need high-performance fluorine-free alternatives that not only comply but also surpass expectations!

Figure 1: Timeline of the EU legislative process regarding the "Fluorine Ban".

Creating a "Super Wear-Resistant Shield" for the Fluorine-Free Era

The general principle of wear resistance: isolate friction, provide long-lasting protection.

Abrasion-resistant agents generally have poor compatibility with the substrate, forming a lubricating layer on the substrate surface, reducing the surface's coefficient of friction, and decreasing the damage to the substrate by the friction pair.

To reduce damage:

1. Reduce the coefficient of friction: decrease surface heat generation and prevent material softening and deformation.

2. Physical isolation of friction pairs: Block direct contact and reduce wear from the source.

How wear-resistant agents can have a lasting effect:

Self-repairing lubrication layer: continuously forms a new protective film for long-lasting wear resistance.

Based on silicone innovation technology, LYSI-704 is committed to:

Complete fluorine-free: Comply with the strictest global environmental regulations.

② Breaking Through the Performance Ceiling: Restructuring the Long-lasting Wear Mechanism

Simplify the production process: Minimal additions for maximum benefits

Core Advantages

Experimental Machine: Sliding Friction and Wear Tester

After multiple controlled variable experiments, the following conclusions can be drawn:

1. Excellent wear resistance and durability

Wear Durability

The sample with added LYSI-704 showed a reduction in average friction coefficient of more than 20%. The friction coefficient directly affects mass wear; the lower the friction coefficient, the lower the mass wear. From the data, it can be observed that the wear resistance lifespan of the sample after the addition is significantly improved, with the wear reduced to as low as 1mg!

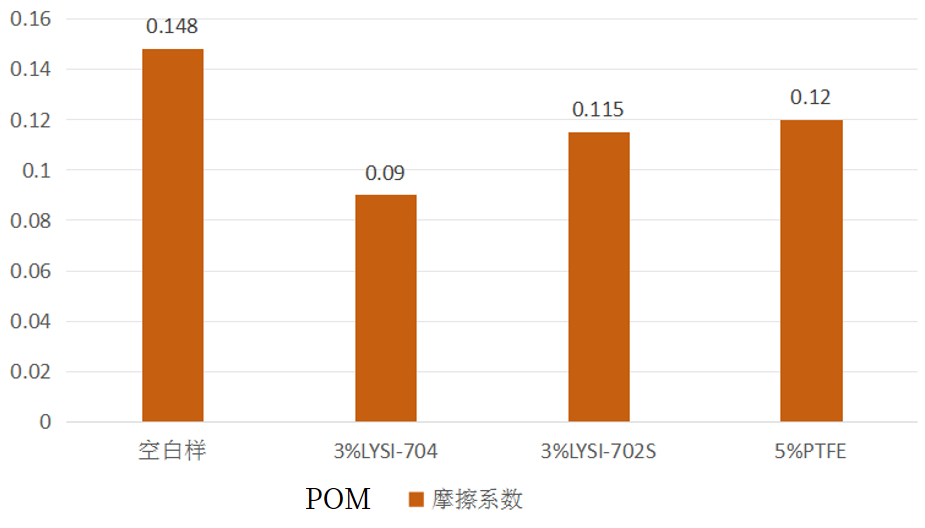

01 POM

Abrasion test conditions: 10 kg weight, sample 40 kg pressure, duration 24 hours.

In the experiment shown in the figure, the friction coefficient of the blank sample in the POM test is 0.148, and the mass wear is 590mg. The sample with added PTFE anti-wear agent shows a slight decrease in friction coefficient and wear amount, but still as high as 0.12 and 224mg. In contrast, the sample with 3% of our new silicone anti-wear agent LYSI-704 shows a decrease in friction coefficient to 0.09 and a reduction in wear mass to 1mg, with wear resistance life improved by 590 times!

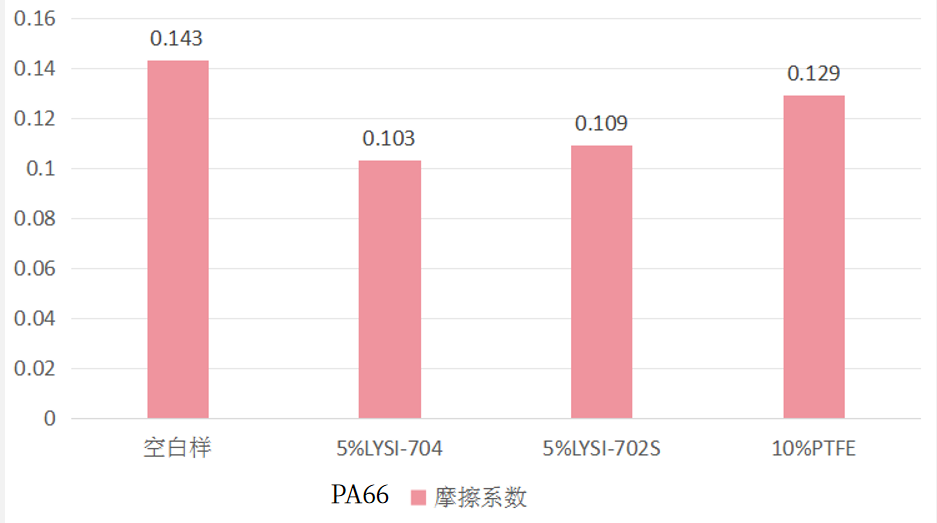

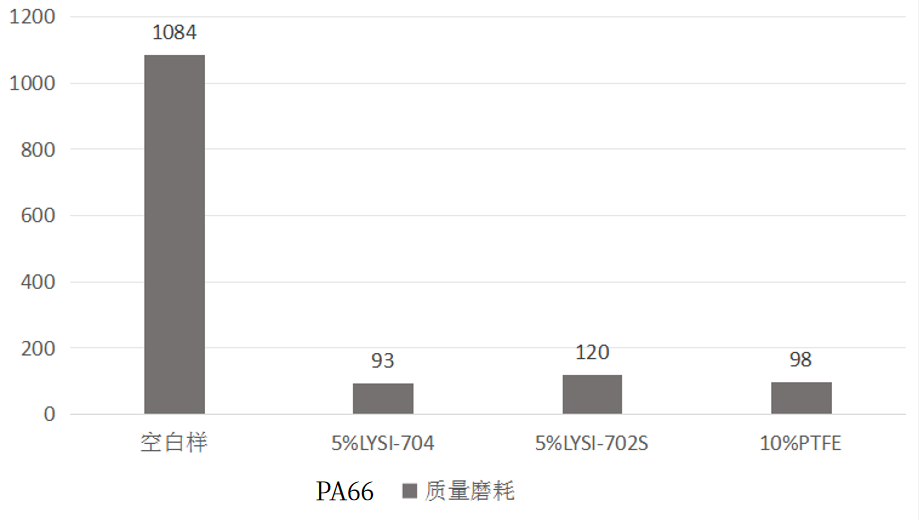

02 PA66

Abrasion test conditions: 10 kg weight, sample 40 kg pressure, duration 3 hours.

In PA66 material, the friction coefficient of the blank sample is 0.143, and the mass wear reaches 1084mg. Although the sample with added PTFE and LYSI-702S shows a significant reduction in friction coefficient and mass wear, it still does not match the friction coefficient of LYSI-704 at 0.103 and mass wear at 93mg. It is evident that LYSI-704 remains the best wear-resistant choice in PA66.

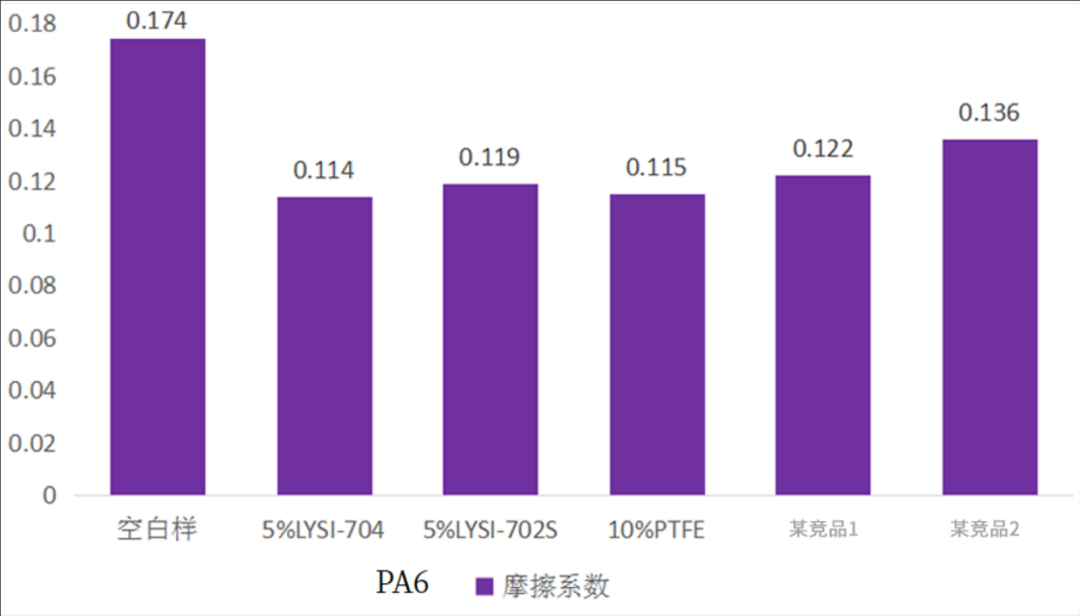

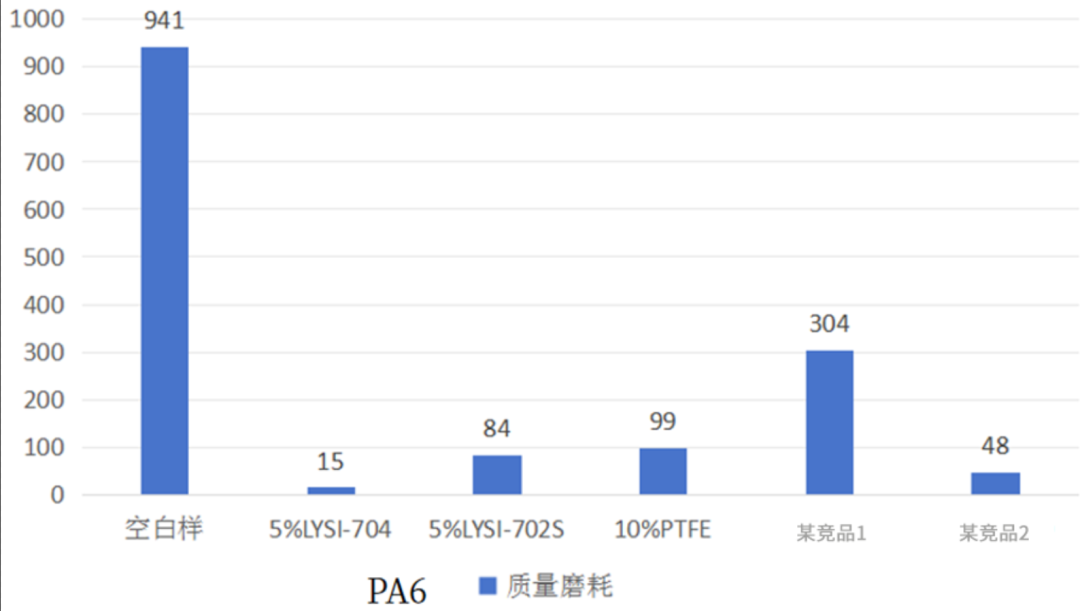

03 PA6

Abrasion test conditions: 10 kg weight, 40 kg pressure on the sample, duration 1 hour.

In the PA6 material, a competitor's product was added as a control experiment. It can be observed that the friction coefficient of the blank PA6 sample is 0.174, with a mass wear of 941mg. The competitor's product, with a 5% addition, has a friction coefficient of over 0.119, and the wear mass is over 48mg. The PTFE with a higher addition level has a friction coefficient of 0.115, and the mass wear reaches 99mg. However, the LYSI-704 at the same low addition level (5%) has the lowest friction coefficient of 0.114, and the mass wear is as low as 15mg, indicating its remarkable effect on PA6, far surpassing products of the same category.

2. Machinability and Revolutionary Nature

RevolutionaryProcessing Friendliness

Easy Dispersion Technology: Dispersion without Agglomeration for More Friendly Processing

Zero Dust Particles: Eliminate Workshop Pollution, Ensure Occupational Health

3. Fluorine-Free Compliance and Cost Optimization

Fluorine-FreeCompliance&Cost Optimization

Trace addition (recommended 2%-5%)

The overall production cost has significantly decreased.

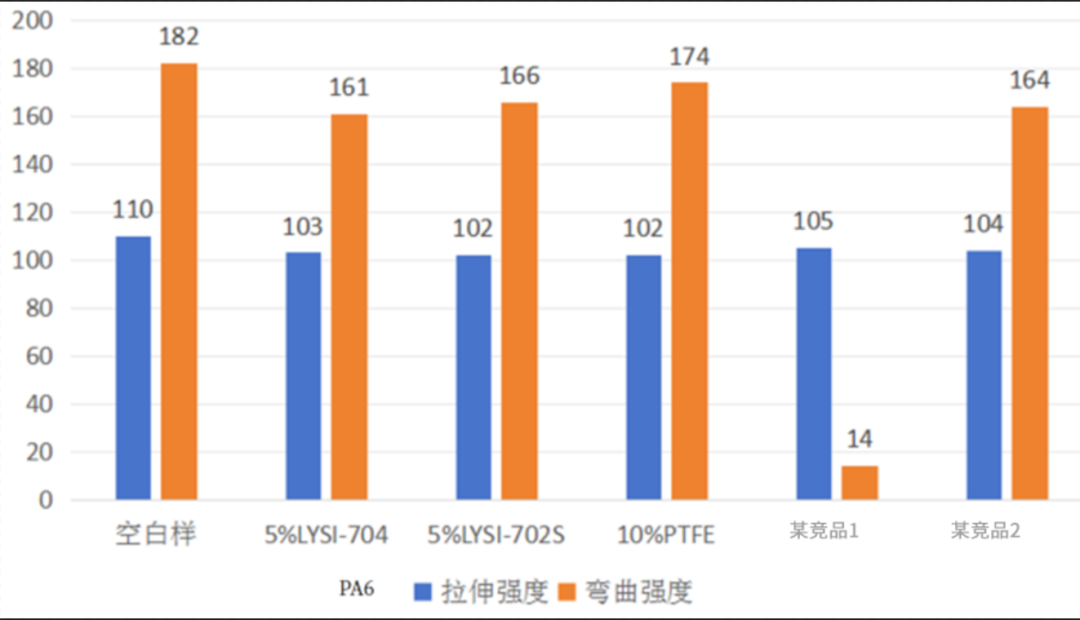

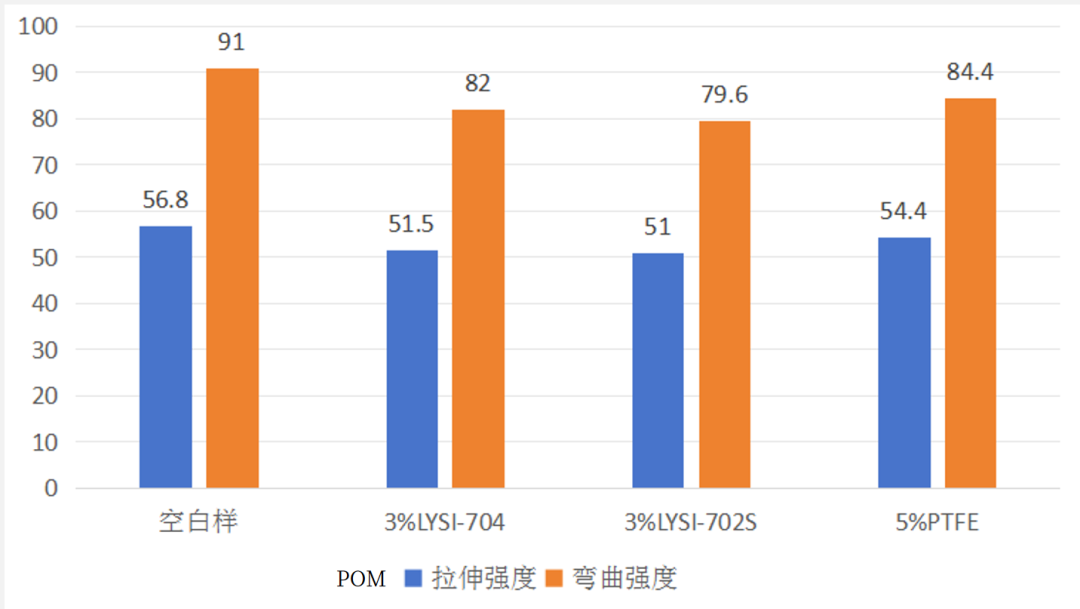

Transparency Technology Statement

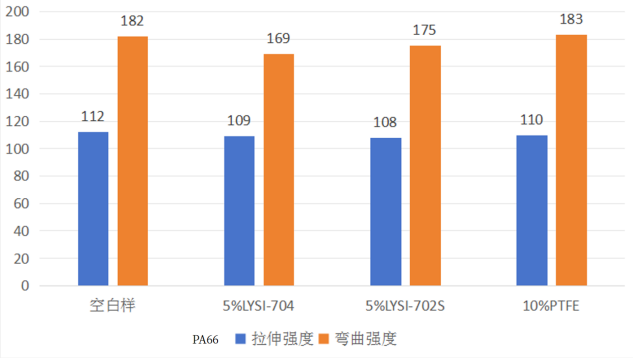

Experimental test data indicate that after the addition of the anti-wear agent, the tensile strength and flexural strength of the samples are affected to varying degrees, but the extent of the impact is within a controllable range.

With fluorine-free technology, build a sustainable industrial future together.

As environmental regulations reshape global supply chains, the upgrading of wear-resistant materials has surpassed mere performance competition, becoming a key component of the green industrial transformation.

Silico's new organic silicon wear-resistant agent carries a triple mission: penetrating the EU PFAS ban barrier with a 100% fluorine-free structure to safeguard the export lifeline of enterprises; achieving a breakthrough in wear resistance through organic silicon molecular design, providing long-term protection in substrates such as POM and nylon; ensuring zero dust particles from the source to protect workers' health, allowing technological advancement and humanistic care to coexist.

When the ban on fluorine is activated, Slike is opening a new track for global manufacturers.Fluorine-free is not a compromise, but a leap in next-generation wear-resistant technology!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track