Finally Someone Explains Plasticizer Clearly!

Friends who work with plastics, coatings, and adhesives, regarding "PlasticizerThese three words must be familiar to you. It is not the main ingredient, yet it often dominates performance; it is used in small amounts, yet it can completely change the “temperament” of a material. Some call it the “softening magician,” while others complain that it is a “migration traitor”…

This seemingly minor molecule, what gives it the power to influence the fate of the entire polymer material? How does it sneak between the molecular chains to "loosen them up"? How should we make good use of it without it "backfiring" on us?

Why do we have to be so entangled with plasticizers?

Think of the products around you: the medical infusion tube as soft as skin; the roll of flooring that never whitens no matter how you fold it; the electrical wire and cable that can be bent repeatedly without breaking...

What determines:

Is the material hard and rigid, or soft and fluffy?

Is the processing smooth and fluid, or does the mold stick and rollers adhere?

After using the product for several years, does it remain as soft as before, or does it become brittle, yellowed, or even develop oily stains?

Tracing back to the source, plasticizers are the "softening hand" in this process!It does not participate in chemical reactions, yet it profoundly influences the physical structure; it is not a framework, yet it determines the material's flexibility and durability. If you choose it wrong or use it improperly, even the most perfect formula may be fleeting. Tell me, can we not fully understand it?

1. What Exactly Are Plasticizers? The "Lubricating Elves" of the Microscopic World

Putting aside chemical terminology, the most straightforward function of a plasticizer is:Make hard materials soft and make brittle materials tough.It is a low-volatility, high-boiling-point organic small molecule that can insert itself between polymer chains, weaken the intermolecular forces, thereby lowering the glass transition temperature (Tg), and increasing the flexibility and plasticity of the material.

Imagine polymer chains as a dense pile of intertwined branches, tangled together with strong attractions, unable to move—this is the rigid and brittle glassy state.

Plasticizer molecules, on the other hand, are likeA group of lubricating little elves sneaked in quietly., they:

Expand the spaceForcibly inserted between molecular chains, "pushing them apart" and increasing the free volume;

- Block attractionUse one's own body to separate originally tightly attracted chain segments, thereby reducing the intermolecular forces between chains.

- Movement of the linker segmentTo make the chain segments start "twisting" at a lower temperature.

The result is that the material's Tg has decreased, it has become softer, easier to process, and more impact-resistant.。

2. How do plasticizers work? A molecular-level "separation and lubrication"

1. The Spacing Effect

Plasticizer molecules insert themselves between polymer chains, acting like "spacers" to forcibly widen the chain distance, reducing friction and attraction between the chain segments, making it easier for the segments to move.

2. The Screening Effect

If the plasticizer molecules themselves contain polar groups (such as ester groups or benzene rings), they can also shield the polar attractions (such as hydrogen bonds and van der Waals forces) between polymer chains, further "loosening" them.

3. The Lubricating Effect

Some plasticizers can also act as lubricants between polymer chains, making it easier for chain segments to slide under external force, thereby improving the material's ductility and flexibility.

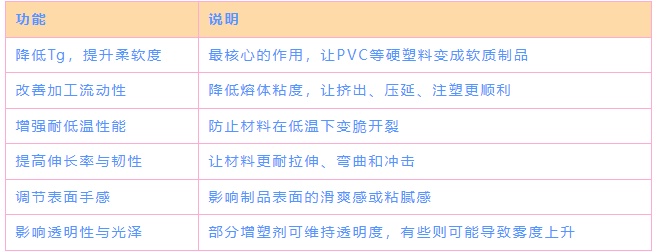

3. Plasticizers are not just about "softness"—they are also versatile "behind-the-scenes players"!

Many people think that plasticizers are only used for making soft products, but their capabilities go far beyond that.

4. Classification of Plasticizers: Who is Your "True Destiny"?

There are many types of plasticizers, commonly including:

1. Phthalate esters (PAEs)

- Representative:DOP(DEHP)、DINP、DIDP

- FeaturesWith good overall performance and low price, it was once mainstream.

- QuestionSome varieties have environmental and health controversies (such as DEHP) and are gradually being replaced.

2. Environmentally Friendly Esters

- RepresentativeDOTP (Dioctyl Terephthalate), ATBC (Acetyl Tributyl Citrate), TOTM (Trioctyl Trimellitate)

- FeaturesResistant to migration, resistant to volatilization, high temperature resistant, more environmentally friendly.

ApplicationsHigh-end fields such as medical devices, automotive interiors, and food packaging

3. Polymer-type plasticizer

- RepresentativePolyester plasticizers (such as adipic acid series, azelaic acid series)

- FeaturesHigh molecular weight, not easy to migrate or extract, excellent durability.

- DisadvantagesHigh price, slightly lower plasticizing efficiency

4. Bio-based plasticizers

- RepresentativeEpoxidized Soybean Oil (ESO), Citrate

- FeaturesRenewable source, environmentally friendly and non-toxic, suitable for food contact and children's products.

- TrendOne of the future development directions

5. How to Choose Plasticizers? Understanding These Parameters Will Ensure You Don't Suffer a Loss!

6. The Application Pitfalls of Plasticizers: Why Do Some People Call Them a "Double-Edged Sword"?

Migration Outflow

Plasticizers are not chemically bonded and will gradually leach out over time.

- The surface is sticky and attracts dust.

- Corrosion or adhesion caused by contact with other materials (such as paint or plastic)

Migration in food packaging affects food safety.

Volatility Loss

In a high-temperature environment, the plasticizer gradually volatilizes.

- The product becomes harder and more brittle

High temperatures inside the car accelerate the aging of the interior.

Extraction

When exposed to oil, water, and detergents, plasticizers are leached out.

- Medical tubing hardens in disinfectant.

The performance of kitchen floor vinyl decreases after encountering oil stains.

Poor Compatibility

Plasticizers will precipitate when they are incompatible with resins.

- Surface blooming

- Decrease in transparency

7. How to Use Plasticizers Effectively? A "Softening Control Manual" for Formula Designers

✅ Selection by Application:

- Medical/food grade → Choose epoxies, citrate esters, DOTP

- Automotive interior → Choose low VOC, high-temperature resistant types (such as TOTM, polyester)

Cables and wires → Choose types with good electrical insulation and resistance to migration.

- Toys/Children’s products → Choose non-toxic and eco-friendly types (such as ATBC, DINCH)

✅ The combination is the way to go.

There is no such thing as a perfect plasticizer.Primary plasticizer + secondary plasticizerCombined use can:

- Balancing cost and performance

Improve the shortcomings of a single plasticizer.

- Improve overall durability

✅Attention to processing technology:

The temperature should not be too high to prevent the plasticizer from decomposing.

Mix thoroughly to prevent localized precipitation.

Post-treatment can promote compatibility and reduce migration.

✅ Focus on environmental protection and regulations:

- REACH, RoHS, CP65... More and more regulations are restricting certain phthalate plasticizers.

The future trend is high molecular weight, low migration, bio-based plasticizers.

In conclusion: Plasticizers are not just synonymous with "softness"!

It is a "space game" on a microscopic level, a "lubrication engineering" on a molecular scale. We use it to adjust softness and hardness, control viscosity, alter texture, and resist low temperatures—but it also brings challenges of migration, volatilization, and extraction.

A good materials engineer does not simply make things "softer," but knows how to strike a balance between softness and durability, performance and environmental sustainability.

Next time you’re holding a piece of soft PVC product, don’t forget:

Behind that touch of softness lies a meticulously choreographed molecular dance.

And you are the one who choreographs the dance.

By mastering plasticizers, you hold the magical key to softening materials.

Make good use of it, so that the material is both soft enough to be comforting and stable enough to last.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track