Fast-drying, high-elasticity, low-temperature curing sealing hardener meets high-performance ink requirements

In today's rapid development of fields such as automotive electronics, flexible displays, photovoltaics, smart packaging, and wearable devices, ink plays a crucial role. It is not only the carrier of pattern colors.Performance, especially adhesion, flexibility, drying speedIt can also directly affect the quality of the final product.

As the ink industry accelerates its transformation towards high performance and differentiation, the market has put forward higher performance requirements for ink.HDI-based polyisocyanateDue to its excellentYellowing resistance, weather resistanceIt has become an important choice for the development of high-performance ink formulations.

Asahi Kasei's HDI (hexamethylene diisocyanate) non-yellowing polyisocyanate product—Duranate™—can help meet the needs of high-performance inks. Quick-drying, flexibility, low-temperature curing, and other differentiated requirementsproducts.

Part.1

Rapid curing, enhance ink adhesion

Asahi Kasei Tenac™ Meet the rapid curing requirements of high-performance inks.While accelerating the drying rate of the coating film, it also helps to achieve a higher crosslinking density, contributing to a good appearance and weather resistance of the coating film, thereby enhancing the adhesion, chemical resistance, and other properties of the ink.

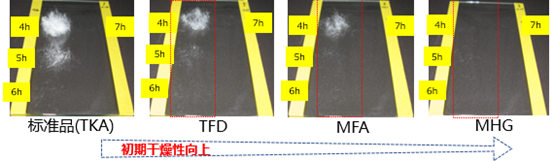

Quick-drying MHG can achieve drying in just 4 hours.While the standard model takes 7 hours to achieve drying.

The above image demonstrates the method of testing drying speed using a cotton ball pressing technique. After a coating film is formed and placed for a period of time, a cotton ball is pressed onto it. The extent of cotton residue left after removal is then observed to assess the drying speed.

Part.2

High elasticity, suitable for substrates requiring high adhesion.

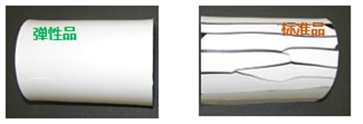

The adhesion of ink to glossy surfaces such as glass and metal, as well as flexible materials like plastic, requires high standards.If the adhesion to the substrate is insufficient, cracking is likely to occur.This affects the quality.

Donar® elastic HDI polyisocyanate product, without the need for additional flexible resins or plasticizers.Typically imparts high elongation and flexibility to the coating film.Enhance adhesion on various substrates.

Low temperature curing blocked Mondur™

Part.3

Low-temperature curing facilitates flexible formulation design.

For a single-component ink system,How to achieve effective curing at lower baking temperaturesIt is a development direction that is widely focused on by the industry.

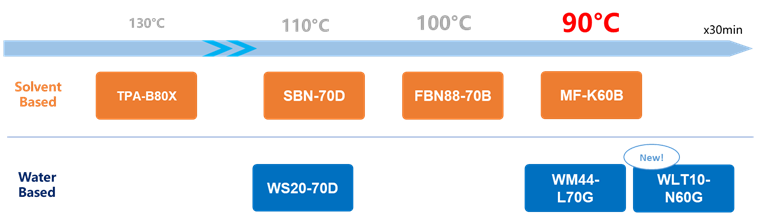

The low-temperature curing blocked Mornic™ product can be used as a crosslinking agent in a one-component ink system, helping to enhance reactive performance and improve film-forming properties.SBN-70D can cure at 110° conditions.As shown in the figure below, Asahi Kasei also offers a series of products with lower unsealing temperatures.

Particularly, the low-temperature activation of water-dispersed Multi-Nydd™ products has been achieved.The upgrade of a single-component baking system from solvent-based to water-based.Under appropriate conditions,It can achieve a curing reaction at approximately 90°.This allows customers to flexibly design formulations and choose baking process conditions.

Asahi Kasei Duranate™

====== HDI series polyisocyanate Duranate™ can provide customized solutions to meet the needs of customers in different market segments.Fast-drying, low-viscosity, water-dispersible, elastic, low-temperature curing, etc.Various high-performance products help meet the formulation development requirements in different application areas.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track