Explosive growth in electric vehicle market: Five "Golden Opportunities" for Established Manufacturers

According to the International Energy Agency's "Global Electric Vehicle Outlook 2024" report, global electric vehicle sales in 2024 are expected to soar to approximately 17 million units, marking a 25% year-on-year increase. Among these, the Chinese market is projected to secure nearly 60% of the share, becoming the "main engine" of global electric vehicle growth. In 2023 alone, 8.1 million new electric vehicles were registered domestically, a staggering 35% increase compared to 2022—meaning that out of every three newly registered vehicles, more than one is an electric vehicle.

At the same time, China is also a major exporter of electric vehicles, with export volumes reaching 1.2 million units in 2023 (an 80% year-on-year increase). Driven by both policy support and market demand, automotive original equipment manufacturers (OEMs) are expanding production and competing fiercely to meet regulatory requirements and the continually growing consumer demand. Given the unique characteristics of electric vehicles, OEMs have an emerging need for batteries, more complex forming processes, and specialized technologies. They are actively seeking "high-energy" forming partners who, in addition to mastering production techniques in the traditional automotive field, must also possess other advanced capabilities.

For molding manufacturers with relevant expertise and resources, filling the supply chain gaps left by traditional supplier networks undoubtedly presents an opportunity. In this article, we will explore the five high-growth opportunity areas directly faced by molding manufacturers in the expanding electric vehicle market and analyze the "ways" and "techniques" to seize these business opportunities and set sail.

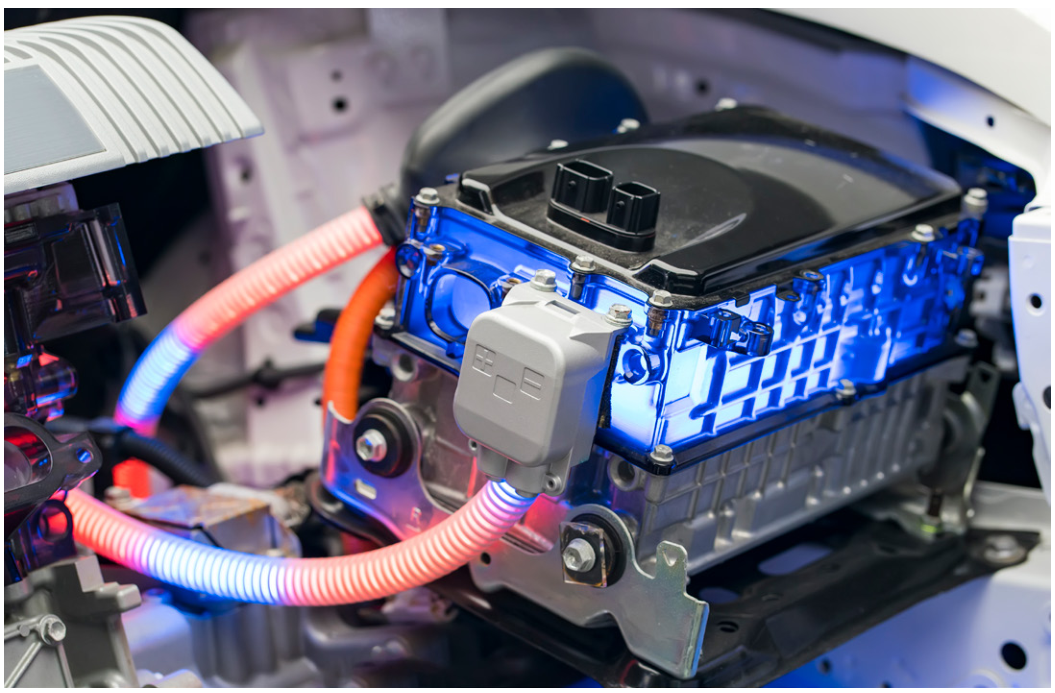

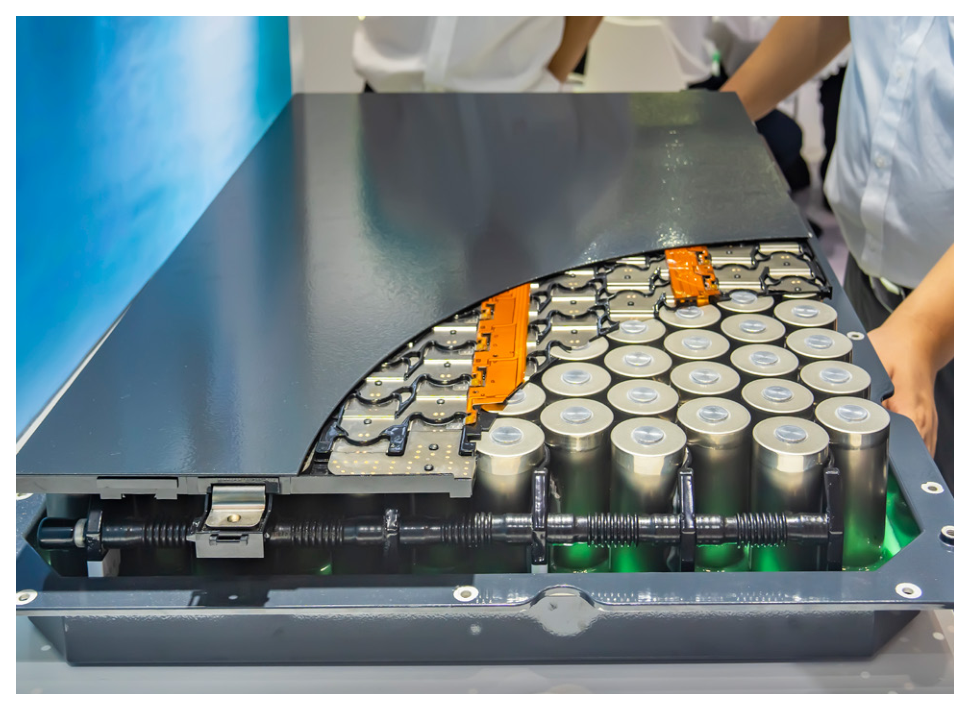

High-performance battery module forming

The battery system is the "heart" that powers electric vehicles with continuous energy. With the surge in battery demand, the market demand for key plastic components that ensure cell integrity, safety, and superior performance is also rising. These components mainly include:

Isolation ring, gasket, and top gasket: play a key role in maintaining cell integrity and ensuring its efficient operation.

Protective casings, covers, trays: Mainly made of polypropylene (PP), they provide protection and insulation for the cells inside electric vehicles to ensure the safety of the vehicle and its passengers.

Special cylindrical battery components: Various components made from different materials, including PP required for high-quality production, PBT for thermal sensitivity, and PFA for high-temperature resistance.

For established manufacturers entering the electric vehicle sector, one of the key challenges is developing specialized skills to properly process highly corrosive and temperature-sensitive materials. Unlike traditional automotive forming which emphasizes wear resistance, electric vehicle battery components require both robustness and extreme precision. This demands high requirements for unique processing settings, temperature, pressure, and speed.

Case Focus: PFA Battery Ring

A leading battery manufacturer faced significant challenges in processing highly corrosive PFA resin to produce critical battery components. Husky utilized a hot-to-cold gating method, equipped with 4-point and 8-point U750 HT-DC nozzle heads, effectively reducing downtime caused by maintenance, achieving over 1.8 million injections, and significantly extending equipment operational time—demonstrating Husky's ability to handle complex materials related to electric vehicle applications.

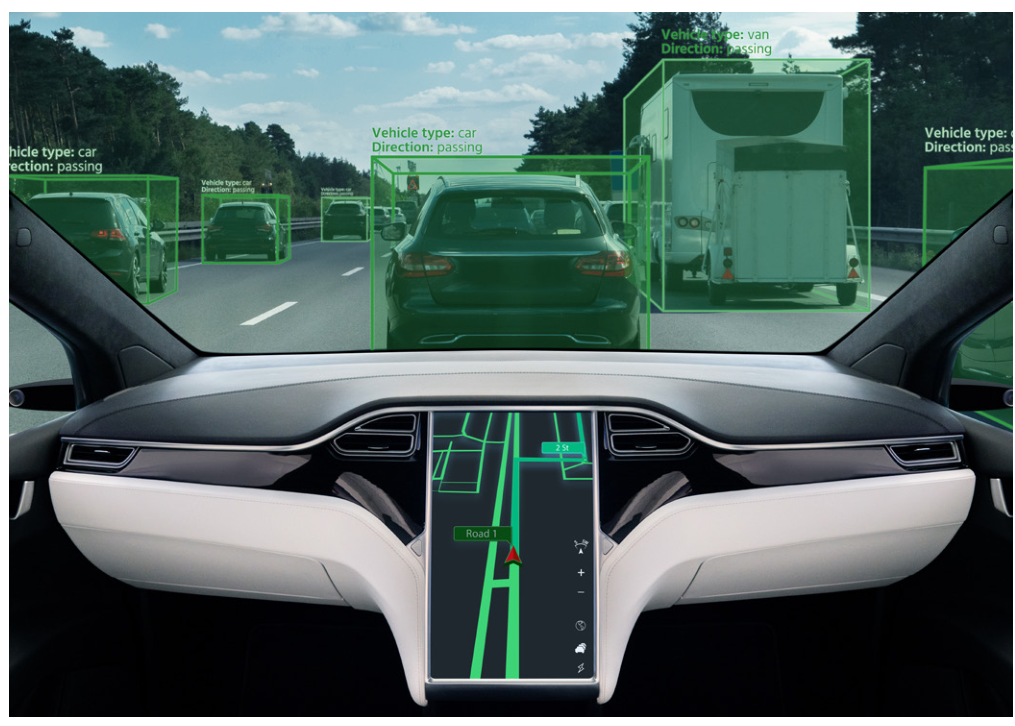

Integration of smart components and sensors

Similar to smartphones, electric vehicles are gradually "evolving" into intelligent machines that require the integration of complex electronic devices, which redefine the user experience by enhancing connectivity, communication, and control functions. This "iteration" indeed brings an increased demand for precision-molded components that support these intelligent systems.

The aforementioned precision molded parts mainly include:

Sensors: Provide real-time data, enabling collision avoidance, lane-keeping assistance, and adaptive cruise control functions.

Camera lens: As the "eyes" of an electric vehicle, it supports functions such as lane departure warning and parking assistance.

Connectors and housings: providing comprehensive protection for complex electronic systems that form the nervous system of modern electric vehicles.

These precision components require special materials to protect delicate and fragile electronic devices while providing adequate sealing and thermal management. Achieving perfection in this regard depends on the ability to achieve optical clarity and dimensional stability. For molding manufacturers with experience in consumer electronics or medical device injection molding, this is akin to having a "halo effect," granting them a natural advantage.

Extended-Range Electric Vehicle Lightweighting Solutions

At present, range anxiety remains a major obstacle to the widespread adoption of electric vehicles. "Lightweighting," which involves reducing the amount of material used in the entire vehicle, has become a key strategy to improve the range of electric vehicles without needing to increase battery capacity, allowing the vehicle to "extend range without adding weight."

For manufacturers, this presents an excellent opportunity to develop thin-walled components that maintain structural integrity while being as lightweight as possible. The key challenge lies in how to create structurally precise components with appropriate wall thickness through complex injection molding processes, achieving the right balance between material reduction and performance requirements.

As OEMs go to great lengths to increase range, manufacturers skilled in mastering these lightweight technologies will become highly sought-after and valuable within the entire electric vehicle supply chain. To achieve lightweighting in the electric vehicle market, it is recommended to consider the following factors:

The application of expertise is not limited to batteries and can be further expanded to interior components, under-the-hood components, and structural elements.

A larger battery system often means increased weight, and developing the corresponding capability to handle this additional weight.

Position your product or solution as a key driver of market differentiation.

Make full use of the expertise in precision forming that many traditional automobile suppliers lack.

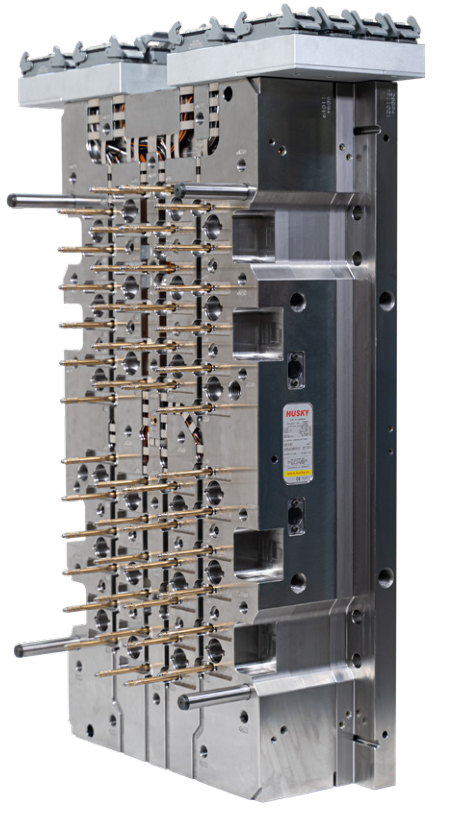

Engineering-grade material processing "new track"

The production of electric vehicle components demands much higher material requirements than traditional fuel vehicles. The transition to electric vehicles will inevitably give rise to unique material challenges, and traditional automotive manufacturers may not yet be prepared to tackle these issues. From the corrosive properties of certain compounds to the stringent protection required for sensitive components, the production of parts in the electric vehicle sector relies heavily on material expertise.

For manufacturers entering the electric vehicle supply chain, mastering the processing technology of engineering-grade polymers undoubtedly offers a highly valuable competitive advantage. This advantage becomes even more apparent as the complexity of components continues to increase with each new generation of vehicles.

Typical engineering polymers include:

Polypropylene (PP): Known for its excellent chemical stability and wear resistance, it is commonly used in battery casings and other components.

Polybutylene terephthalate (PBT): Extremely high thermal management requirements during processing

Perfluoroalkoxy (PFA): Requires specialized technology and experience for high-temperature processing.

The complexity of these materials poses severe challenges in process control. When processing engineering-grade polymers, molders must ensure consistent part quality, even if the material faces degradation risks due to high temperatures or prolonged processing times.

Application Focus: Hot-to-Cold Three-Board Forming

Husky converted a 32-cavity PBT resin project from a cold runner to an 8-point U500 VX hot runner system, reducing the production cycle by 33% (from 12 seconds to 8 seconds); the number of molds required drastically decreased from 44 to 29, significantly improving production efficiency; meanwhile, the weight of the cold runner was also reduced by 76%.

Production efficiency and component quality are firmly grasped.

Nowadays, as the electric vehicle market continues to expand, established manufacturers must meet the growing demand while ensuring that safety-critical components meet ideal quality standards. Leading automotive OEMs are increasingly favoring partners that can simultaneously meet the demands for "high volume, high quality" manufacturing, driving the production model towards advanced process control and real-time quality monitoring.

To "win a beautiful battle" in this field, molding manufacturers must:

Achieving a perfect balance between strict quality control and high cavity molding.

While ensuring the parts are flawless, shorten the molding cycle.

With precise process control, reduce material waste.

Ensure that the assembly and installation processes adhere to strict dimensional tolerances.

Maintain mechanical strength to ensure stable and consistent component filling.

With real-time monitoring and automated process adjustments, molding manufacturers will gain a competitive advantage, providing electric vehicle manufacturers with the scale, efficiency, and precision they need.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track