Exploring the composition, benefits, and application considerations of talc masterbatch: An Essential Additive for Enhanced Plastic Durability!

In the modern plastics industry, durability is not just an ideal characteristic but a necessity. From automotive parts to household items, consumers expect products to withstand stress, temperature fluctuations, and everyday use.

One of the most effective and cost-efficient ways for manufacturers to achieve this goal is to use talc masterbatch, which has become the preferred solution for enhancing plastics, helping to extend the lifespan of plastics while maintaining cost competitiveness.

What is talcum powder masterbatch?

Talc masterbatch is a polymer-based compound that contains finely ground talc particles dispersed in a carrier resin, typically polypropylene (PP) or polyethylene (PE). It is produced using a twin-screw extruder to mix the talc with molten polymer and additives. The mixture is then cooled and formed into uniform small pellets.

At this stage, since talcum powder is incorporated into the polymer matrix, its dispersibility is far superior to that of on-site mixed raw material powder. This provides plastic manufacturers with consistent mechanical properties and more convenient quality control.

The final product is a ready-to-use granule that manufacturers can directly feed into extrusion or injection molding equipment. Unlike talc raw materials that require additional mixing and dispersion, talc masterbatch simplifies the processing while ensuring uniform distribution of the mineral filler.

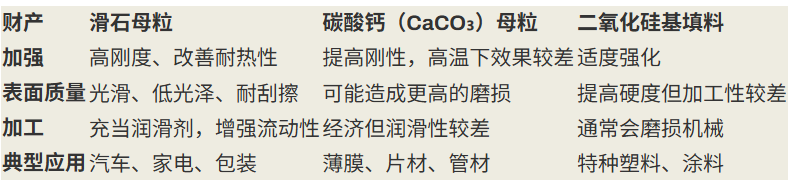

Talc is not the only mineral filler used in plastics, but compared to common alternatives, it has unique advantages:

In fact,Talc masterbatch is chosen when durability, thermal stability, and dimensional control are of primary concern.

2. The unique properties of talcum powder in plastics

2.1 Sheet-like Crystal Structure

Talc powder has a layered or flaky structure. When talc powder is dispersed in a polymer, these flakes align neatly to form a barrier structure. This reinforcement mechanism can increase stiffness and reduce creep (the tendency of plastics to slowly deform under load). Research published in "Polymer Composites" indicates that talc-filled polypropylene can achieve up to a 40% increase in tensile modulus compared to unfilled polypropylene.

2.2 Thermal Resistance and Dimensional Stability

Plastics typically expand and contract with changes in temperature. The thermal stability of talc can reduce this effect, thereby improving the heat deflection temperature (HDT) and dimensional stability. In automotive applications, this means that dashboards and interior panels can remain warp-resistant even under prolonged sunlight exposure.

Adding talc to polypropylene can increase the HDT from about 100°C to over 130°C, enabling a wider range of applications without the need for expensive engineering plastics.

2.3 Lubricating Function

Talc particles have natural lubricating properties, which can reduce friction during processing. This can enhance melt flow, lower energy consumption, and minimize mechanical wear. Compared to other fillers such as silica, talc is less abrasive, which can extend equipment life while maintaining production efficiency.

3. How talc masterbatch enhances the durability of plastics

3.1. Mechanical Strength

Durability begins with mechanical properties. Adding talc masterbatch can improve:

Stiffness and rigidity:Talc enhances the polymer structure, making the parts more resistant to bending and deformation.

Creep resistance:Plastic with added talc can maintain its shape under long-term pressure, which is crucial for products such as automotive components and structural profiles.

An article published on ScienceDirect shows that the flexural modulus of polypropylene filled with 20–30% talc is significantly increased, making it suitable for demanding load-bearing components.

3.2 Improve Heat Resistance and Thermal Stability

Heat resistance is another key aspect of durability. Pure PP or PE softens at relatively low temperatures, limiting their applications. By adding talc masterbatch, manufacturers can extend their usable temperature range.

This is particularly important in automotive and electrical applications, as the components in these applications are subjected to both high temperatures and mechanical stress. Talc can reduce thermal expansion and enhance the heat deflection temperature (HDT), ensuring that components can function properly even under conditions where unfilled plastics would deform.

3.3 Scratch and Abrasion Resistance

Daily use can make plastic surfaces prone to damage. Talc masterbatch, with its hard and smooth talc particles, enhances scratch and abrasion resistance. In the field of automotive interiors, this can be reflected in dashboards, panels, and trims, enabling them to resist visible scratches and maintain long-lasting aesthetics.

Similarly, in household appliances and storage containers, talc-enhanced materials ensure that surfaces remain clean and resistant to wear during repeated use.

3.4 Dimensional Stability

Warping and shrinkage are common issues in plastic molding. Since talc can reduce thermal expansion, plastics with added talc masterbatch can maintain better dimensional stability during processing and final use.

For example, injection-molded polypropylene with added talc has a lower shrinkage rate, allowing for tighter tolerances and fewer defects. This reliability is highly attractive to manufacturers who need to ensure product dimensional consistency, such as cap and closure producers in the packaging industry.

3.5 Moisture and Chemical Resistance

Durability also depends on the interaction between plastics and the environment. Polymers can absorb moisture or degrade when in contact with chemicals, while talc masterbatches help to enhance their durability.

Talc's hydrophobicity can reduce the water absorption rate of plastics, making them less likely to swell or become brittle in humid environments. Additionally, plastics filled with talc exhibit greater resistance to chemicals such as oils and detergents, which is crucial for household products and industrial components.

4. Case Studies and Data

Scientific research and industrial experience have confirmed the performance advantages of talc-filled plastics.

4.1 Strength Improvement

A study published in "Today's Materials: Conference Records" indicates that polypropylene composites with 20% talc added have a tensile modulus that is 40% to 45% higher than that of pure polypropylene. This makes them more suitable for manufacturing load-bearing components where rigidity is crucial.

4.2 Heat Resistance

Data from the Journal of Polymer Testing indicate that talc-reinforced polypropylene can increase the heat deflection temperature (HDT) by 20-30°C, extending the usability of the plastic in high-temperature environments.

4.3 Industry Benchmark

In the automotive field, original equipment manufacturers often specify talc-filled polypropylene (PP) grades for interior parts because they are superior to calcium carbonate-filled grades in terms of scratch resistance and dimensional stability. This practical benchmark further demonstrates why talc masterbatches have become a standard in automotive design.

5. Economic and Environmental Benefits

The advantages of talc masterbatch lie not only in its durability but also in its contribution to cost-effectiveness and sustainability.

5.1 Cost savings compared to engineering plastics

Engineering plastics such as ABS, polyamide, or polycarbonate offer excellent performance but are much more expensive. Talc masterbatch can help manufacturers achieve stiffness and heat resistance comparable to PP or PE at a lower price. This alternative material reduces the overall material cost while maintaining the desired durability.

5.2 Automotive and Packaging Lightweighting

Lightweighting is a key strategy in industries such as automotive and packaging to reduce energy consumption and transportation costs. Since talc powder can enhance stiffness, it allows for achieving the same mechanical performance with less material. This means that thinner wall thicknesses or lighter component weights can be achieved without compromising durability.

5.3 Compatibility with Recycling

Recycling has become central to the sustainability roadmap of the plastics industry. Talc masterbatches are compatible with multiple recycling streams and can even enhance the performance of recycled plastics by improving stiffness and dimensional stability. This enables manufacturers to more easily incorporate more recycled materials while still meeting durability requirements.

6. Frequently Asked Questions about Talcum Powder (People Also Ask)

Q. Is talc masterbatch safe for food packaging?

Yes, food-grade talc masterbatch is widely used in rigid packaging applications such as caps and containers. Approval by regulatory authorities depends on the supplier, so manufacturers should ensure compliance with FDA or EU food contact standards.

Q. What is the difference between talcum powder and calcium carbonate in plastics?

Both are mineral fillers, but talc has superior reinforcing properties, scratch resistance, and thermal stability. Calcium carbonate is typically used to reduce film costs, while talc is the preferred choice when durability and thermal performance are crucial.

Q. Can talc masterbatch improve the heat resistance of PP and PE?

Talc powder can increase the heat distortion temperature of polypropylene, allowing it to be used in high-temperature environments such as automotive interiors or under-the-hood components.

Q. What is the common usage amount of talcum powder?

The typical addition amount ranges from 10% to 40% depending on the specific application. The packaging industry usually uses lower addition amounts to increase stiffness and opacity, while automotive or construction components typically use higher addition amounts.

Durability is one of the defining characteristics of high-quality plastic products, and talc masterbatch has been proven to be an effective method for achieving durability. By using talc to enhance polymers, manufacturers can significantly improve their stiffness, heat resistance, scratch resistance, and dimensional stability, while being highly cost-competitive.

From automobiles to consumer goods, from packaging to construction, talc masterbatches offer versatile solutions that meet both performance requirements and sustainability goals. For businesses competing in a fiercely competitive market, adopting talc masterbatches is not only about durability but also about building long-term reliability and consumer trust.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track